7

4. Service points

z

Lead-free solder

This product uses lead-free solder (unleaded) to help protect the environment. Please read these instructions

before attempting any soldering work.

Caution:

Always wear safety glasses to prevent fumes or molten solder from getting into

the eyes. Lead-free solder can splatter at high temperatures (600

℃

).

Lead-free solder indicator

Printed circuit boards using lead-free solder are engraved with an "F."

Properties of lead-free solder

The melting point of lead-free solder is 40-50

℃

higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended. Although servicing with

leaded solder is possible, there are a few precautions that have to be taken. (Not taking these precautions

may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

z

Remove all lead-free solder from soldered joints when replacing components.

z

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead-free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead-free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

z

Soldering iron with temperature control function (temperature range: 320-450

℃

)

Recommended temperature range per part:

Part

Soldering iron temperature

Mounting (chips) on mounted PCB

320

℃

±30

℃

Mounting (chips) on empty PCB

380

℃

±30

℃

Chassis, metallic shield, etc.

420

℃

±30

℃

(

1) EMI PWB, AUDIO TRANSFER PWB, RS-232 PWB, AUDIO PWB, KEY PWB, IR PWB, I/O PWB,

CONNECTOR PWB, SPEAKER CONNECTOR PWB

(2) MAIN PWB

(3) ATSC BOX(Digital Tuner Module) / TUNER

(4) POWER PWB

(5) PDP MODULE (is all lead free solder. X-SUS PWB, Y-SUS PWB, LOGIC PWB, ADDRESS PWB, SDM PWB)

The PWB assembly which has used lead free solder

Содержание 42HDF52A

Страница 9: ......

Страница 10: ......

Страница 11: ......

Страница 12: ......

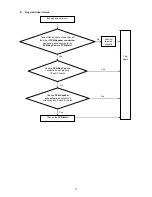

Страница 26: ...26 7 Block Diagram z Plasma Television ...

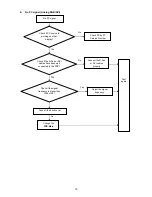

Страница 27: ...27 z ATSC Module ...

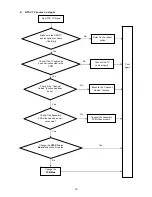

Страница 28: ...28 z Power Module ...

Страница 29: ...29 8 Connection Diagram ...

Страница 31: ...31 10 Basic Block Diagram ...

Страница 32: ...32 11 Printed Wiring Board Diagram z Main Board Top Side ...

Страница 33: ...33 z Main Board Bottom Side ...

Страница 34: ...34 z I O Board Top Side z RS 232 Board Top Side Audio Board Top Side ...

Страница 35: ...35 z Audio Transfer Board Top Side L Bottom Side R ...

Страница 36: ...36 z Power EMI Board Top Side L Bottom Side R z ATSC Connector Board Top Side L Bottom Side R ...

Страница 38: ...38 z Power Board ...

Страница 39: ...39 12 Disassembly Diagram z Mechanical ...

Страница 40: ...40 z Packing ...