7

6. Warming up (Fig. 11)

The grease lubrication system in this unit may

require warming up in cold regions.

Position the end of the bit so makes contact with

the concrete, turn on the switch and perform the

warming up operation. Make sure that a hitting

sound is produced and then use the unit.

Fig. 11

CAUTION:

When the warming up operation is performed, hold

the side handle and the main body securely with

both hands to maintain a secure grip and be careful

not to twist your body by the jammed drill bit.

DRILLING AND DRIVING-IN OPERATIONS FOR

ANCHORS

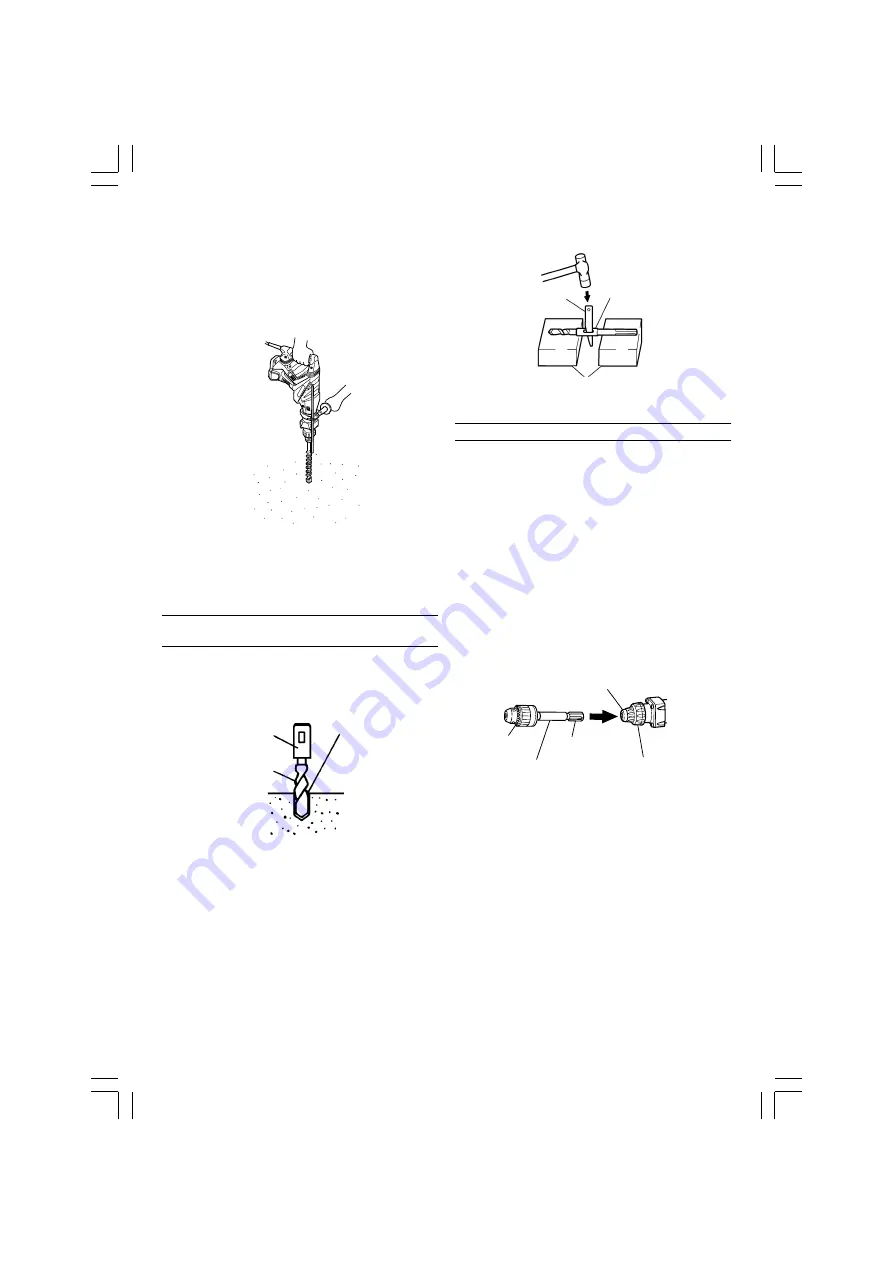

1. When a taper shank adapter is used. (Fig. 12)

(1) Install drill bit with taper shank in the taper shank

adapter.

Fig. 12

(2) Turn the power on and drill a base hole to the depth

sounded by indicating groove on the drill bit.

(3) After cleaning out dust with a syringe, attach the

plug to the anchor tip and drive in the anchor with

a manual hammer.

(4) To remove the drill bit (taper shank), insert the

cotter into the slot of the taper shank adapter and

strike the head of the cotter with a manual hammer

supporting on a rest. (

Fig. 13

)

Fig. 13

USING DRILL CHUCK, CHUCK ADAPTER

Note that this machine can be used at “rotation only”

if separately sold parts such as drill chuck and chuck

adapter are attached. Use it with the selector lever

positioned at “ro hammering”.

CAUTION:

During operation, be sure to grip the handle and

the side handle firmly to prevent your body from

swaying.

(1) Switching to “ro hammering”

For switching to “ro hammering”, follow the

same procedures mentioned in [3. When drilling at

“ro hammering”].

(2) Attaching chuck adapter to drill chuck (

Fig. 14

)

(a) Attach the chuck adapter to the drill chuck.

(b) The SDS max shank of the chuck adapter is

equivalent to the drill bit. Therefore, follow the

same procedure as [How to install tool] for

attaching and detaching.

Fig. 14

(3) Drilling

(a) Even if you apply more-than-required pressure to

the machine body, drilling can never be performed

as quickly as you expect. Applying more force or

pressure to the machine body than what is needed,

on the contrary, damages the drill tip, resulting in

the declined working efficiency and shortened life

of this machine.

(b) A drill can snap sometimes when drilling is almost

finished. It is important to relax your thrusting

pressure when drilling is nearing the end.

Taper shank adapter

Drill bit (taper shank)

Indicating groove

shows standard

depth matching

the outside

diameter of the

anchor for

drilling.

Taper shank adapter

Cotter

Part of SDS

max shank

Chuck adapter

Drill chuck

Grip

Front cap

Rest

01Eng_DH50MRY_ENG

7/18/13, 8:54 AM

7

Содержание DH 50MR

Страница 10: ...10 DH50MRY 02Back_DH50MRY_ENG 07 8 8 19 06 10 ...

Страница 12: ...12 DH50MR 02Back_DH50MRY_ENG 07 8 8 19 06 12 ...

Страница 14: ...14 02Back_DH50MRY_ENG 07 8 8 19 06 14 ...

Страница 15: ...15 02Back_DH50MRY_ENG 07 8 8 19 06 15 ...