14

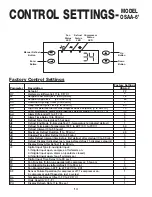

CONTROL SETTINGS-

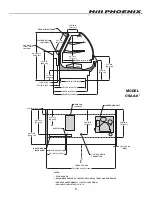

MODEL

OSAA-6’

Manual Defrost

Button

Enter

Button

Up

Button

Down

Button

Fan

Status

LED

Compressor

Status

LED

Defrost

Status

LED

Factory Settings

Parameter

Description

OSAA-6’

Setpoint

HY

Hysteresis (differential) [1 to 9

o

F/

o

C]

LL

Setpoint Low Limit [67

o

F (55

o

C) to HL]

HL

Setpoint High Limit

[LL to 99

o

F/

o

C]

CC

Anti-Short Cycling Timer [0 to 9 min.]

Co

Deep Freeze Cycle Time [0 to 99 min.]

AH

High Temperature Alarm Value (degrees above setpoint) [0 to 55

o

F/

o

C]

AL

Low Temperature Alarm Value (degrees below setpoint) [-50 to 0

o

F/

o

C]

Ad

Alarm Differential [1 to 9

o

F/

o

C]

At

Alarm Time Delay [0 to 99 min.]

dF

Defrost Type (0-electrical; 1-hot gas)

dE

Defrost End Mode (0-timed defrost; 1-temperature terminated defrost)

dt

Defrost Termination Temperature [32

o

F to 68

o

F (0

o

C to 20

o

C)]

di

Defrost Interval [0 to 99 hours]

dd

Maximum Defrost Duration [1 to 99 min.]

dC

Dripping Time After Defrost [0 to 99 min.]

dU

Initial Defrost Interval (time before first defrost after startup) [0 to 99 min.]

dP

Defrost Display (0-displays last value before defrost; 1-displays setpoint)

dr

Display Delay After Defrost [1 to 99 min.

iF

Digital Input Type (0-no digital input;

1-if digital input open, compres. off w/alarm on:

2-if digital input open, alarm on (contacts closed);

3-if digital input open, fan off w/alarm on)

id

Digital Input Time Delay [0 to 99 sec.]

FF

Fan Function (0-fan runs parallel with compressor; 1-fan on)

Fd

Fan Start-Up Delay (after defrost) [0 to 99 min.]

Fr

Fan Start-Up Temp. [-22

o

F to 41

o

F/-30

o

C to 5

o

C]

SF

Sensor Failure Operation (0-compressor off; 1-compressor on;

2-compressor on/off based on last 4 cycles)

So

Temperature Sensor Offset [-20

o

to 20

o

F/

o

C]

Un

Units Used (0-

o

C; 1-

o

F)

PU

Display Refresh Rate [1 to 99 sec.]

Factory Control Settings

22

3

18

30

1

60

10

-10

5

3

0

1

50

8

45

0

0

0

5

0

0

1

0

40

1

0

1

1

Содержание Origin2 OSAA

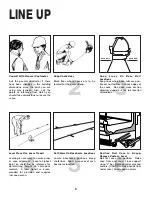

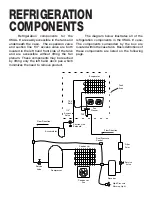

Страница 1: ...DELI C A S E S MODEL OSAA HANDBOOK INSTALLATION OPERATION 9 03 P061773M...

Страница 2: ......

Страница 4: ......

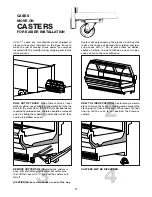

Страница 8: ...31 11 16 71 1 4 4 6 CASE FRONT OF CASE 4 GENERAL INFORMATION BASEHORSE LOCATIONS FOR MODEL OSAA...

Страница 29: ...25 NOTES...

Страница 30: ...26 NOTES...