20

21

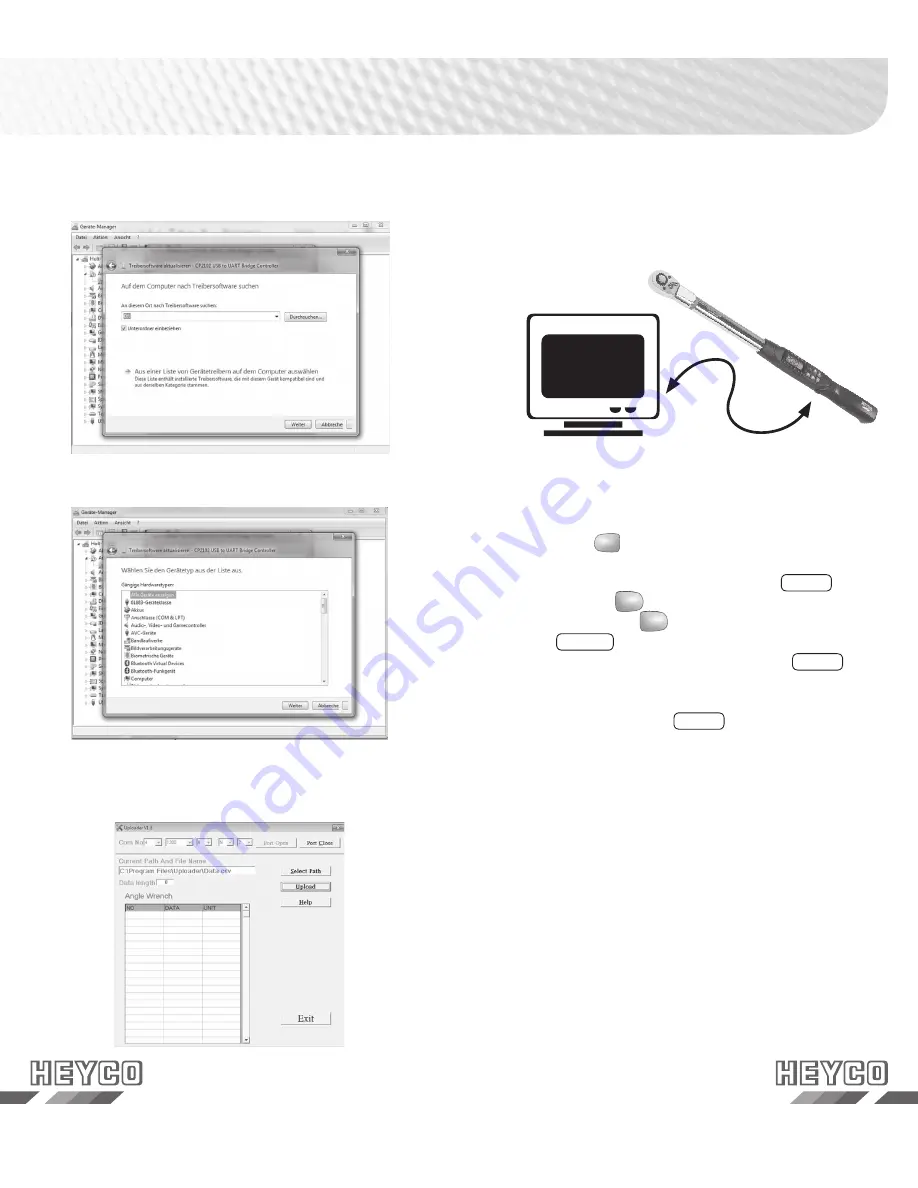

Please click „drivers to be selected from list“

Please select the respective Com Port in the

„Uploader“ and klick „Port open“

Please click „Next“

Connection of the communication cable

Turn off the Torque wrench and connect the accessory cable

between the COM Port of the PC and the torque wrench.

Transmission of recorded data

1. Please press

C

after successfull connection to turn on

the Torque Wrench.

2. Please change in to the operation mode SEND by

pressing button

U/S

until you reach the menue. By

pressing the button

U/S

several times you reach the

mode COMU .

By pressing the arrow keys you reach the SEND

mode.

3. Please start the uploader program on your PC.

4. Please select the correct COM port in the uploader

program.

5. Then please select the fi le path to save the uploaded

data.

6. Finally, press Upload to transmit the torque records to the

PC.

7. The uploaded datas are shown in a column and saved in

a *.csv fi le. Please use Microsoft Excel to view *.csv fi le.