Herrtronic

®

RDU-D Supplement

I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

7

www.herrmidifier-hvac.com

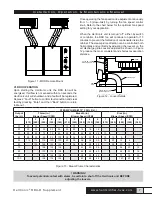

Figure 11 - MDD Remote Mount

VI. RDU OPERATION

Upon starting the Herrtronic unit, the RDU fan will be

energized. If airflow is not sensed within ten seconds, the

Herrtronic unit will shutdown and a fault will be registered.

Depress ‘”Fault” button to confirm fault condition and clear

fault by pressing “Enter” and then “Back” button to return

to Menu 1.

Once operating, the fan speed can be adjusted continuously

from 1—5 (slow—fast) by turning the fan speed control

knob. Refer to the chart below for the optimum fan speed

setting for your application.

When the Herrtronic unit is turned “off”, either by switch

or controller, the RDU fan will continue to operate for 15

minutes to prevent the formation of condensate inside the

cabinet. The steam plume direction can be controlled both

horizontally and vertically by adjusting the louvers on the

air discharge grille.Louvers adjusted as shown in Figure

12 produce the most consistent and shortest evaporation

distance.

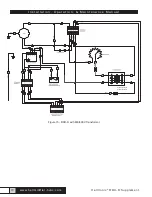

Figure 12 - Louver Details

Figure 11 - MDD Remote Mount

HERRTRONIC MD

STEAM INLET UNION

(REMOTE MOUNT)

STEAM HOSE

DRAIN

LINE

BLOWER

OPTIMUM LOUVER

DIRECTION, DOWN 30°

Figure 14 - Optimum Louver Placement

Figure 13 - Steam Plume Characteristics

! WARNING!

To avoid potential contact with steam, be certain to shut off the Herrtronic unit BEFORE

adjusting the louvers.

STEAM PLUME (@75° F, 55% R.H.)

Output

lbs./Hr

Throw (in.)

Blower Speed (CFM)

Breadth (in.)

Blower Speed (CFM)

Rise (in.)

Blower Speed (CFM)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

1

(210)

2

(240)

3

(280)

4

(320)

5

(365)

10

20

15

15

15

20

50

35

30

35

35

20

20

18

18

18

30

90

80

75

70

60

28

26

24

24

24

10

40

98

92

90

94

100

36

36

36

32

26

18

12

6

50

112

112

116

120

120

40

36

36

36

30

36

22

12

6

60

120

126

130

134

36

34

28

28

58

30

14

6

70

126

132

138

42

40

36

36

20

12

80

130

138

156

48

42

40

52

24

16

90

136

144

156

58

52

46

72

36

20

100

126

138

156

60

60

48

120

50

25