Herrtronic

®

MD Series

I n s t a l l a t i o n , O p e r a t i o n , & M a i n t e n a n c e M a n u a l

22

www.herrmidifier-hvac.com

V. TROUBLESHOOTING GUIDE

General Maintenance Notes

WARNING!

High Voltage components are present in both the cylinder and

electrical compartments. Maintenance must be performed by

qualified individuals. Absolutely no other components may be

mounted inside or electrically tapped into humidifier without

voiding the warranty.

A. Externally, controls of many configurations may be used

with your new MD series humidifier. Herrmidifier strongly

recommends the use of some type of control humidistat,

a high limit humidistat, and an air proving switch to insure

proper operation of your humidification system.

B. Electrode boilers operate by passing current through the

water utilizing the conductivity of the water itself as a cur-

rent path. The flow of current through the water generates

heat which boils the water and produces the steam required

for humidification. The diagnostic features of the MD series

humidifier are designed to help you maintain and optimize

your system for years of service. If the fault light is illumi-

nated, see the diagnostic section on page 19.

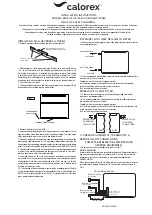

C. The wiring diagram, illustrated on page 34 (for MDD units,

the wiring diagram is located on pages 11 and 12 of the

“MDD Supplement”), clearly shows the path of the 24 VAC

control circuit. Control voltage leaves the transformer,

passes through a fuse and then into the circuit board. The

microprocessor has inputs and outputs for the humidistats

or sensors, contactor auxiliary pole, differential pressure

switch and the control loop. Power for the control loop goes

through the external off switch (optional), the door interlock

switch, and then back to the microprocessor. Understand-

ing the wiring diagram will give you a better idea of the logic

of the MD series humidifier and simplify your troubleshoot

-

ing.

D. If any changes to the physical board set-up are made, i.e.

capacity changes or resistor, the unit must be reset. You

may reset the unit by depressing the “reset” button on the

back of the board or turning the unit off and on through the

disconnect (See PC Board diagram on page 28).

E. If the circuit board needs to be changed, make sure the

ribbon cable connector from the main board to the display

board is as originally supplied (red stripe on top at LCD and

on the right at PCB). Reattach the (three) 11 Pin connectors

in the same manner. (J1, J3 and J5)

Operating The Humidifier Without External Controls

The humidifier has the capability to operate without any external

signals being sent to the unit. Being able to isolate the humidifier

from the external controls is invaluable in troubleshooting. The

unit can be “jumped-out” whether it’s mode 1, 2, 3.

A. Mode 1 - On/Off

1. Remove any control wiring supplied by others; mark

wires for re-attachment.

2. Jump terminals 1 & 2 on controls terminal strip.

3. Jump terminals 1 & 3 on controls terminal strip

4. Jump terminals 4 & 5 on controls terminal strip.

5.

After unit is turned ON, it should fill to 100% output (or

capacity setpoint) or cylinder full.

6.

After confirming proper operation, reattach controls for

normal operation and remove added jumpers.

B. Mode 2 - Proportional

This signal is typically supplied by others. The MD has 2 sepa-

rate VDC power supplies accessible from the controls terminal

strip (as shown on page 26). Either one of these outputs will be

sufficient to bring the MD into an operational state. You will need

to know the control signal being supplied and select the 5 VDC

or 2O VDC output from the control terminal strip. The humidifier

will react in proportion to its programmed signal range.

Example: The humidifier is set up for 0-10 VDC signal from the

BMS. The humidifier is being jumped-out with the 5 VDC signal

from pole 6 to pole 5 on the control terminal strip. You can ex-

pect the humidifier to fill to 50% output or cylinder full.

1.

Remove any field installed control wires; mark for re-

attachment.

2. Through Menu 5, disable limit input (if applicable).

3. Jump terminals 1 & 2 on controls terminal strip.

4. Jump terminals 1 & 3 on controls terminal strip.

5. Select 5 VDC from control terminal strip pole 6 or 20

VDC from control terminal strip pole 7 to jump to pole 5

on the controls terminal strip.

6. If signal provided is other than VDC, use the following

comparisons: mADC; 20mA = 20 VDC, resistance; 135

ohms = 2 VDC

C. Mode 3 - Propor Integral

If a problem is detected in the sensors, the diagnostics will pick

up the problem and display a fault with the sensor. To jump-out,

follow the steps 1-4 listed for Mode 2 above, then follow steps 1

through 3 below.

1. If the control signal is a DC voltage type with a maximum

signal level of 5 VDC or greater, or a DC millilamp type with

a maximum signal level of 20 mA or greater, apply a jumper

wire between poles 5 & 6 on the controls terminal strip.

2. A control RH level will be indicated based on the jumped

input signal and the factory board set up for the actual field

control signal. i.e., board factory set for a 0-10 VDC control

signal, jumper wire applied between poles 5 & 6, the indi-

cated control RH level (via Menu #1) will be approximately

50%.

3. Adjust the control setpoint relative to the control RH level

via Menu #2, keeping in mind the bandwidth, i.e., control

RH level is 50%, Bandwidth is +/- 10%, adjust the control

setpoint to 60%, or greater, to obtain 100% output from the

unit.