Installation instructions

Incremental Shaft Encoder Type RI 42

Item No. 2 521 251, Edition 3 161105 HOR Page 1/1

Hengstler GmbH

Uhlandstr. 49 Tel. +49(0)7424-89 0

D-78554 Aldingen Fax +49(0)7424-89500

Mechanical data

Mounting

round flange

1)

Shaft diameter

6 mm

Absolute max. shaft load

radial 30 N (6.5 lbs), axial 15 N (3.3 lbs)

Max. speed

10,000 RPM

Torque

≤

1 Ncm

Protection class housing/ball bearing IP 65/64

2)

Operating temperature

-1

0 … +60 °C

(Open Collector: 0 ... +60°C)

Storage temperature

–25 … +85 °C

Vibration performance (IEC 68-2-6)

100 m/s

2

(10 … 2,000 Hz)

Shock resistance (IEC 68-2-27)1,000 m/s

2

(6 ms)

Connection

cable axial

Material

flange: aluminium, cap: plastics

Weight

75 g approx.

1)

use threads M3 for fastening

2)

no standing water allowed at the shaft entrance or at the ball bearing

Technical specifications subject to change without notice.

Ordering data (see identification plate)

R I 4 2 –

/

·

1

A

R

4

0

O

Standard

Supply voltage

A

5 VDC

E

10 … 30 VDC

C*

10 … 24 VDC

Type of flange

R

Round flange

Shaft

diameter

1

6 mm

Number of pulses

5 … 1,024

Protection

class

4

IP 64

Type of connection

A

Cable axial

**

* only with Output S

Connection diagram

Output

Colour (PVC)RS 422 (T),

Push-pull (K, D),

Push-pull

RS 422 (R)Open Collector (S)

complementary (I)

white

Channel A

Channel A

Channel A

white/brown Channel A

Channel A

green

Channel B

Channel B

Channel B

green/brown Channel B

Channel B

yellow

Channel N

Channel N

Channel N

yellow/brownChannel N

Channel N

yellow/black Sense GND/Alarm

1)

Alarm

Alarm

yellow/red

Sense V

CC

Sense V

CC

red

5 V DC

5/10…30/10…24 VDC

10…30 V DC

black

GND

GND

GND

1 )

Sense GND for RS 422 (T), Alarm for RS 422 (R)

R 100

Output

K

Push-pull short circuit proof

D

Push-pull 5 V, ± 30 mA

S

Open Collector NPN

T

RS 422 + Sense

R

RS 422 + Alarm

I

Push-pull complementary

** Special types are additionally marked by an ordering code

-S

. In this case customer specifications are to

be applied.

If you don’t know these please call us for the specifications, indicating the encoder ordering code.

Electrical data

General design

as per DIN VDE 0160, protection class III,

contamination level 2, overvoltage class II

Power consumption

5V/40 mA, 24V/30 mA (10...30 V), 24V/40 mA (10...24V)

Supply voltage U

B

(SELV)5 V DC

±

10%

10...30 VDC 10...24 VDC

Output circuit

1)

PP

PP

RS422

PP, PPcomp. O.C. NPN

Code letter

K

D

R, T

K, I

S

Output load [mA]

±

10

±

30

±

30

±

30

±

30

Output voltage [V]

High

≥

2.5

≥

2.5

≥

2.5

U

B

-3

U

B

-2

Low

≤

0.5

≤

0.5

≤

0.5

≤

2

≤

0.4

Pulse rise time [ns]

250

100

100

2000

4000

Max. pulse frequency [kHz]

300

300

300

200

50

Reverse polarity protection

yes

no

no

yes

yes

Short-circuit protection

yes

1

channel

1

channel

yes

yes

2)

Pulse duty factor

1 : 1

Pulse width error

± 25° electrical (RS 422, Push-pull)

± 30° electrical (Open Collector NPN)

Phase shift

90° (distance from Channel A to B is at least

0.45 µs, at 300 kHz)

Pulse shape

rectangular

Alarm output

Open Collector, NPN (with U

B

=5 VDC or 10...24 VDC:

max. 5 mA, 24 V; with U

B

=10...30 VDC: max. 5 mA, 32 V)

1)

PP=Push-pull; PPcomp.=Push-pull complementary; RS422=Line driver;

O.C. NPN=Open Collector NPN with internal pull up-resistor (10 k

Ω)

2)

not aU

B

Introduction

These installation instructions are provided for the connection and starting

procedure of your shaft encoders.

Safety and Operating Instructions

• The incremental shaft encoders of the type RI 42 model series are quality

products manufactured in accordance with established electrical engineering

standards. The units have been delivered from the factory in perfect confor-

mance to safety regulations.

To maintain this condition and to ensure trouble-free operation, please

observe the technical specifications of this document.

• Installation and mounting may only be performed by an electrotechnical

expert!

• The units may only be operated within the limits specified by the technical data.

•

Maximum operating voltages must not be exceeded!

The units are designed complying with VDE 0160, protection class III.

To prevent dangerous structure-borne currents, the equipment has to be run

on safety extra-low voltage (SELV) and must be in an area of equipotential

bonding.

• Application: Industrial processes and control systems.

Overvoltage at the connecting terminals must be limited to the values within

overvoltage category II.

• Please avoid shocks to the housing – especially to the encoder shaft – and

axial or radial overload to the encoder shaft.

• Maximum accuracy and durability of our shaft encoders is only granted

when using suitable couplings.

• The high-quality EMC-specifications are only valid together with standard-

type cables and plugs. When using screened cables, the screen must broadly

be connected with ground on both ends. Likewise, the voltage-supply cables

should entirely be screened. If this is not possible you will have to take

appropriate filtering measures.

• Installation environment and wiring are influential on the encoder's EMC:

Thus the installer must secure EMC of the whole facility (device).

• Transient peaks on the power supply leads are to be limited by the pre-

connected power unit to a maximum of 1000 V.

• In electrostaticly threatened areas please take care for neat ESD-protection

of plug and connecting cable during installation work.

• Specified maximum shaft loads are only given under restrictions:

– Full bearing life of 1 x 10

10

revolutions (typ.) will be reached at 35% of full

rated shaft load

– a bearing life of 1 x 10

8

revolutions (typ.) will be reached at 100% of full

rated shaft load.

Item

No. 2 521 251, 3 1

61105 HOR

• For use in class II circuits only

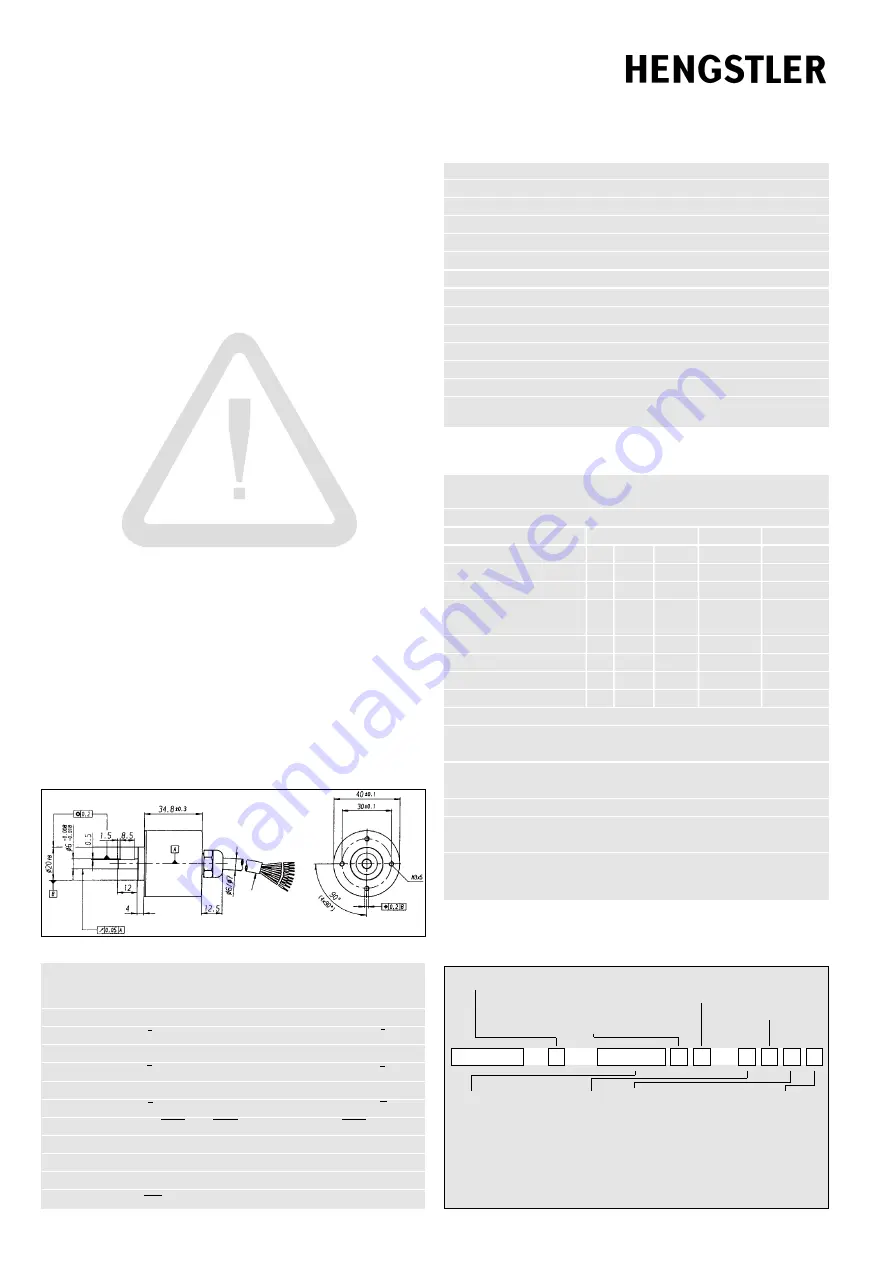

Dimensioned drawing