Page 11 of 19

CUS

-009

-0008

-0

3

5.3 Double deck rotisserie

5.3.1 Preparation

1. Using a crowbar and hammer, remove the top and sides of each packing crate.

2. Remove all accessories and loose items from in and around the equipment. Keep the accessories separate for

each rotisserie.

3. Remove all wrapping from the rotisseries. Care should be taken not to scratch any surfaces if a knife is being

used. Remove all wood blocks around the casters that might hinder the removal from the pallets.

4. The bottom rotisserie (the one equipped with caster wheels) must be unpacked and set on the floor first.

5. Determine if your rotisserie comes with a wood lifting jig (located inside one of the rotisseries) or the metal lifting

bracket (installed on the bottom rotisserie). If using a wood lifting jig then follow the instructions in section 5.3.2, if

using the metal bracket then follow the instructions in 5.3.3.

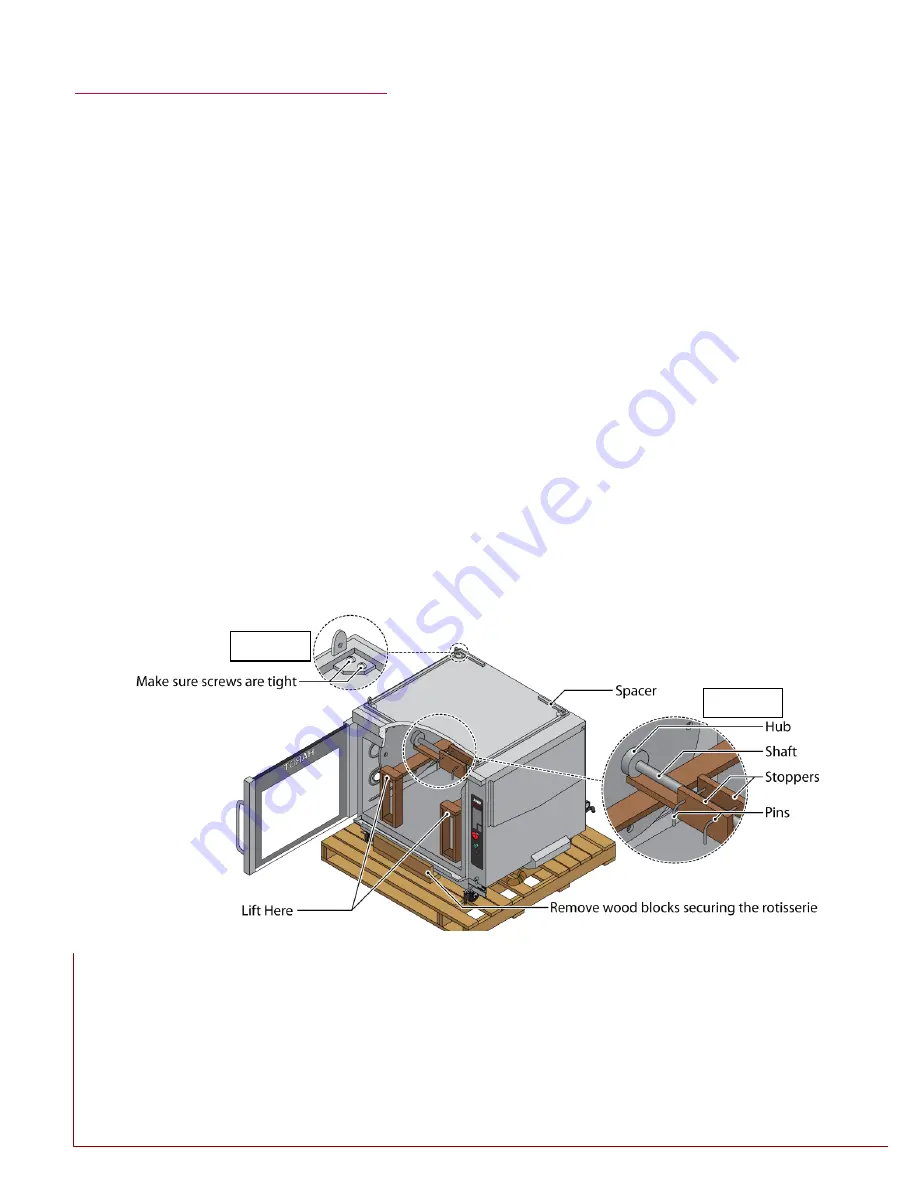

5.3.2 Using the wood lifting jig

1. Open the door on the rotisserie.

2. Insert the lifting jig inside the cooking cavity, taking care not to damage the door. The proper orientation is shown

in

3. Align the jig so the shaft is between the two stoppers built into the jig as shown in detail 2 of

4. Lift the jig and insert the two pins that hold the jig on the shaft.

5. The rotisserie

may now be lifted by inserting the lift’s forks in the openings of the jig. The lifting jig should support

the rotisserie

from the rotating plates’ hubs and NOT from the shaft as shown in detail 2 of

Figure 5-3: Wood lifting jig in bottom rotisserie (with wheels)

Detail 1

Detail 2