4.

Using a drill and 3/8” drill bit (not provided), drill the two previously marked holes

completely through the top of the workbench.

5.

Place the Mini Rolling Mill back upon the workbench, and align the two 3/8”

mounting holes on the Base Body (part #1) with the two previously drilled holes

in the workbench. Then, firmly secure the Mini Rolling Mill to the workbench with

two 3/8” diameter bolts of appropriate length, two lock washers, and two nuts (not

provided).

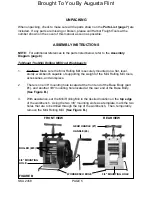

(See Figure B.)

To Attach The Handle:

1.

To attach the Handle (part #4) to the Mini Rolling Mill, insert the Handle onto its

Handle Shaft and secure the Handle with the Bolt and Washer (part #5).

(See Figure A.)

OPERATING INSTRUCTIONS

NOTE:

For additional references to the parts listed below, refer to the

Assembly

Diagram (page 8)

.

1.

Insert the Gear Handle (part #7) into the top of the Mini Rolling Mill.

(See Figure B.)

2.

Prepare the material to be rolled: anneal (heat and then cool to soften and re-

duce brittleness) the piece of sheet or ingot, pickle (preserve) it, and rinse it with

clean water.

3.

Feed the metal into the

front

end of the Mini Rolling Mill by inserting the metal

between the two Rollers (part #23). Then, turn the Handle (part #4)

clockwise

.

Apply snug (but not overpowering) pressure on the Rollers.

NOTE:

To apply

greater pressure on the Rollers, turn the Gear Handle (part #7)

clockwise

. To

apply less pressure, turn the Gear Handle

counterclockwise

.

(See Figure B.)

4.

After rolling the metal completely through the Mini Rolling Mill, flip the metal end to

end before rolling it through again. This allows for a more even roll.

5.

Before passing the metal through the Rollers (part #23) again, apply greater

pressure to the Rollers until the metal passes through snugly.

(See Figure B.)

6.

If the metal becomes too hard to roll, it must be annealed (heated, then cooled)

again. Then roll the metal through the Rollers (part #23), repeating as necessary

until the desired thickness is achieved.

(See Figure B.)

7.

NOTE:

When rolling silver sheet, it may be necessary to anneal (heat, then cool)

the sheet after rolling it from

3.0mm

to

1.0mm

in thickness. For 14kt gold, the

annealing may be necessary after rolling from

3.0mm

to

2.0mm

.

SKU 2458

PAGE 6

Brought To You By Augusta Flint