Model

Low TPR-3SL 040L-EP TPR-3SL 055L-EP TPR-3SL 070L-EP TPR-3SL 090L-EP TPR-3SL 130L-EP TPR-3SL 160L-EP

High TPR-3SL 040H-EP TPR-3SL 055H-EP TPR-3SL 070H-EP TPR-3SL 090H-EP TPR-3SL 130H-EP TPR-3SL 160H-EP

Power supply

voltage

Low

100

-

240 V a.c.

High

100

-

440 V a.c.

Circuit input power

100

-

240 V a.c. 18 W

※ Rated current 130 A, 160 A specification Separate input of FAN power

-

24 V d.c. 10 W

Power frequency

50/60 Hz (Dual usage)

Rated current

40 A

55 A

70 A

90 A

130 A

160 A

Applying load

Resistive load

Current input

4

-

20 mA d.c. (Impedance : 100 Ω)

Control method

Phase control, Fixed Cycle control, Variable Cycle control

Movement type

SOFT START, SOFT UP/DOWN

Output voltage

More than 98 % of the power supply voltage (In case of maximum current input)

Cooling method

Forced cooling

Display method

Display by LED

Insulation resistance

Min 100 MΩ (Base on 500 V d.c. mega)

Output control range

0 ~ 100 %

Dielectric strength

3000 V a.c. 50/60 Hz for 1 min

Line noise

Noise by noise simulator (2,500 V)

Ambient temperature &

Humidity

0 ~ 40 ℃(Without Condensation), 30 ~ 85 % RH

Storage temperature

-

25 ~ 70 ℃

Approval

Weight(g)

4,324

9,194

9,288

Thyristor Power Regulator

TPR-3SL-EP

Thank you for purchasing Hanyoung Nux products. Please read the

instruction manual carefully before using this product, and use the product

correctly. Also, please keep this manual where you can view it any time.

MB0602KE201103

INSTRUCTION MANUAL

▍Safety information

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor injury or property damage

• If there is a possibility that a malfunction or abnormality of this

product may lead to a serious accident, install an appropriate

protection circuit on the outside.

• Any use of the product other than those specified by the

manufacturer may result in personal injury or property damage.

• Since this product is not designed as a safety device if it is used

with systems, machines and equipment that could lead to a risk

of life or property damage, please implement safety devices and

protections for both lives and the applications and plan for

preventing accidents.

• Please supply the rated power voltage, in order to prevent

product breakdowns or malfunctions.

• To prevent electric shocks and malfunctions, do not supply the

power until the wiring is completed.

• Never disassemble, modify, process, improve or repair this

product, as it may cause abnormal operations, electric shocks or fires.

• Please disassemble the product after turning OFF the power.

Failure to do so may result in electric shocks, product abnormal

operations or malfunctions.

• Since the product operating environment influences the product

performance and expected life span, please avoid using in the

following places.

· a place where humidity is high and air flow is inappropriate.

· a place where dust or impurity accumulates, ambient temperature is

high and vibration level is high.

· a place where corrosive gases

(such as harmful gases, ammonia, etc.) and flammable gases occur.

· a place where there is direct vibration and a large physical impact

to the product.

· a place where there is water, oil, chemicals, steam, dust, salt, iron or

others (Contamination class 1 or 2).

· a place where excessive amounts of inductive interference and

electrostatic and magnetic noise occur.

· a place where heat accumulation occurs due to direct sunlight or

radiant heat.

• Please do not wipe the product with organic solvents such as alcohol,

benzene, etc. (use neutral detergents).

• When water enters, short circuit or fire may occur, so please inspect

the product carefully.

• Please connect the product and other units after turning off all the

power of the product, instruments and units.

• Please make sure that the thyristor power regulator (TPR) is installed vertically.

• Please install the product inside of the control panel and install an

exhaust fan onto the top of the control panel.

• Pay attention to the edge of heat sink which is sharp.

• Please close the cover after installation in the place in which there is a cover.

• The external circuit connected with the product should be connected

by an insulated circuit more than basic insulation.

• The temperature of the body and the heat sink may be extremely high

when electric current is applied, which may cause burns.

To prevent electric shock while it is running, put to earth with the fixed

screw of the unit and do not touch the heat sink since it is very hot. Do

not touch or contact the input/output terminals because they cause

electric shock.

Please read the safety information carefully before the use, and use the product correctly. The alerts declared in the

manual are classified into Danger, Warning and Caution according to their importance

DANGER

WARNING

CAUTION

28, Gilpa-ro 71beon-gil,

Michuhol-gu, Incheon, Korea

TEL : +82-32-876-4697

http://www.hanyoungnux.com

HANYOUNGNUX CO.,LTD

■ Communication protocol selection

• Set the communication protocol with DIP S/W no. 8

RTU

ASCⅡ

■ Address (ID) setting

• Set the ID with DIP S/W no. 1~5

• Set 1 ~ 31 (except 0).

• When communication setting is changed,

the change is applied after reset.

1. Communication method : RS485 2

-

wire half-duplex

2. Communication speed : 2400, 4800, 9600, 19200 bps

3. Maximum number of connections : 31

4. Protocol : ModBus RTU, ModBus ASCII

▍Communication

■ Communication setting (ModBus RTU/ASCⅡ)

Communication settings

Communication speed

2400, 4800, 9600, 19200

bps

Protocol

ModBus RTU

ModBus ASC II

Parity bit

Even

None

bit

Data bit

8

7

bit

Stop bit

1

bit

ID

1 ~ 31

Structure (RTU)

Division Address(ID) Function Start Address No. of Data CRC

Request

1

1

2

2

2

Division Address(ID) Function No. of Data

Data

CRC

Request

1

1

1

2

2

2400 bps

■ Communication speed setting

• Set the communication speed with DIP S/W no. 6 or 7

2400 bps 4800 bps 9600 bps 19200 bps

ID:1

ID:2

ID:3

ID:4

ID:5

ID:6

▍Function descriptions

7. Tighten the screws of the terminal block with the

specified torque.

M3.5: 0.6 ~ 1.2 N.m / M6: 4.41 ~ 4.9 N.m /

M8 : 8.82 ~ 9.80 N.m

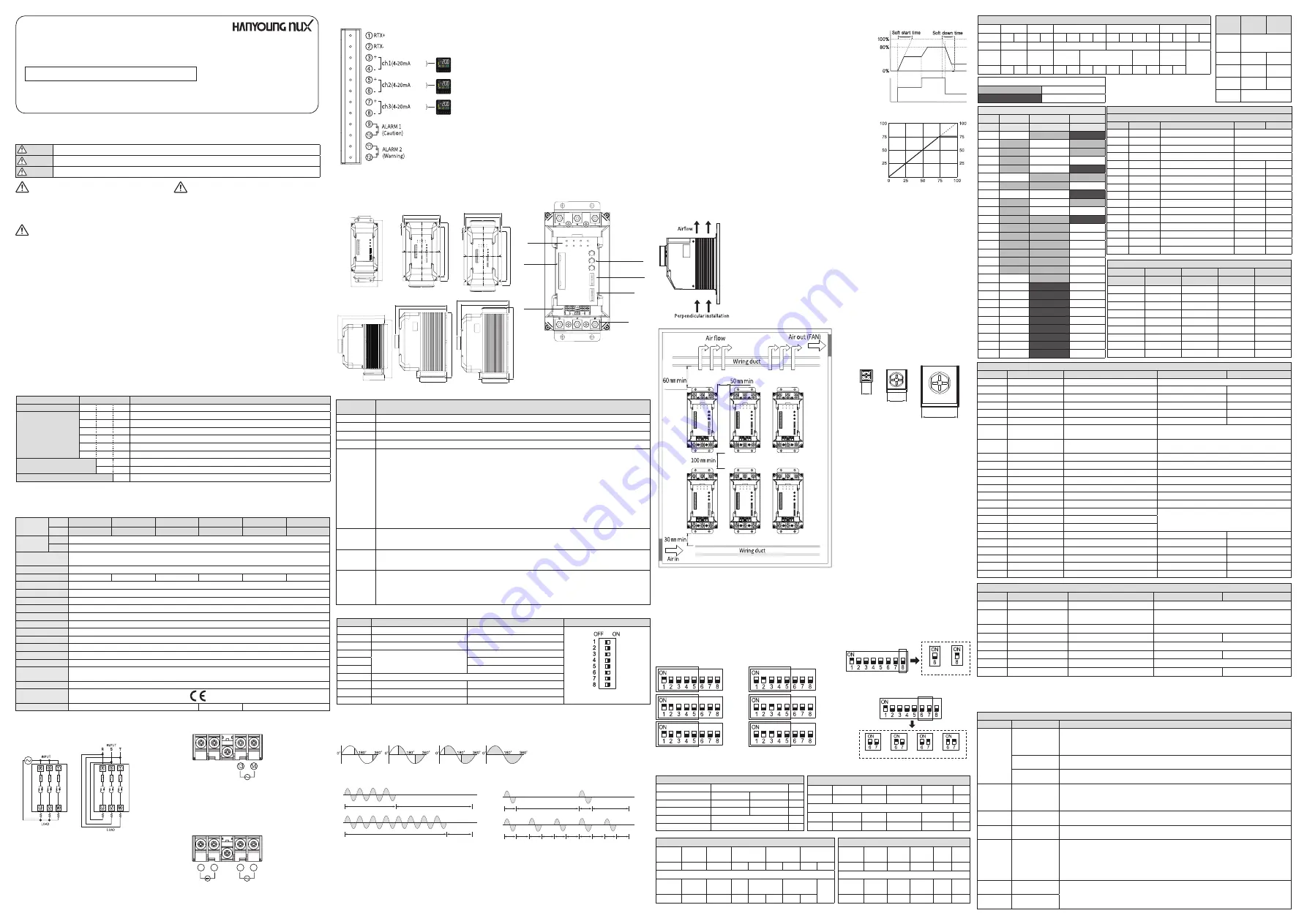

▍Specification

▍Suffix code

Model

Code

Content

TPR-2SL

⃞

⃞

- ⃞

Slim type Single phase power regulator

Rated current

040

40 A

055

55 A

070

70 A

090

90 A

130

130 A

160

160 A

Power supply voltage

L

100

-

240 V a.c. (Low)

H

100

-

440 V a.c. (High)

Option

EP

Each phase control (3 device individual control)

※ The circuit power and fan power must be applied separately 100

-

240 V a.c.

※ 130 A, 160 A products are FAN power 24 V d.c. Voltage must be applied.

▍Connection diagram

■ Connection diagram of load terminal

■ Restart function

When a warning or caution alarm occurs, TPR gives alarm 1 or 2 or stop the output.

This function is used to return to normal operation mode when factors caused errors are eliminated.

This function is able to set up when Fuse/Power Supply is in disorder, Heat sink over heat, SCR Short is occurred.

(When Overcurrent is occurred, this function is not working)

0VUQVU

DVSSFOU

*OQVU

TJHOBM

5JNF

5JNF

0

VU

QV

UW

PM

UB

HF

*OQVUTJHOBM

0VUQVUMJNJUWBMVF

1. Please install it perpendicularly. If the product is installed vertically in unavoidable circumstances,

please use 50% of rated current.

2. When multiple products are closely installed, please install them with keeping a distance of more than

a width of 5cm and a length of 10cm as shown in the picture.

3. In order to not block the air flow, please install the wiring duct less than the half of the heat sink height.

4. Please consider whether the air flow is good enough when installing the product. If the ambient

temperature is as low as possible in the inside then the life span of the product is increasing as the

durability and reliability of the product are improving. The operating ambient temperature is 0 ~ 40 ℃.

Please refer to the following graph. However, if the ambient temperature is higher than 40 ℃,

the maximum load current is decreasing like the below.

5. When connecting R and U, please securely fasten them with using crimp connectors since high current

flows into these terminals. If the contact surface of the connectors and terminals are poor, it may lead

to a fire since the wires and terminal gets overheated.

6. Before applying power, this model need more than the third class grounding to prevent electric shock.

This model does not have separate grounding terminal so we suggest using grounding terminal and

bracket together when install this model to a panel.

▍Installation

M3.5

M6

M8

M6

M3.5

M8

M8

M6

M3.5

26.0

15.0

7.3

M3.5

M6

M8

M6

M3.5

M8

M8

M6

M3.5

26.0

15.0

7.3

• Circuit

power

• 40/55/70A

Structure (ASCⅡ)

Division Address

(ID)

Function Start

Address

No. of

Data

LRC

Request

2

2

4

4

2

Division Address

(ID)

Function No. of

Data

Data

LRC

Response

2

2

2

4

2

Example (RTU)

Division Address

(ID)

Function Start Address No. of Data

CRC

Request

0x01

0x03

0x00 0x01 0x00 0x01 0xD5 0xCA

Division Address

(ID)

Function No. of

Data

Data

CRC

Response

0x01

0x03

0x02 0x00 0x00 0xB8 0x44

· Inside of TPR, the fuse is installed in the R,S,T input power supply

portion depending on thespecification of options

· When connecting terminals, please use crimp connectors and

securely fasten them due to the high current flow.

(Max space for solder less terminal connection is

40/55/70 A : 16 mm, 90/130 A : 26 mm)

· Only one channel can be used per temperature controller.

(Serial connection disabled)

· Since the internal GND is not separated, use a module or

temperature controller that has separate analog inputs for each

channel.

■ Connection diagram of input signal and power terminal

*/165

7%$

*/165

7"$

*/165

7"$

*/165

7%$

*/165

7"$

*/165

7"$

● 40/55/70/90 A

● 130/160 A

· Extra input power supply (For circuit power and FAX

operation power) : 100

-

240 V a.c. (13, 14)

Have to connect power to operate unit

(Even if do not need to use FAN).

· Extra input power supply (For circuit power) : 13, 14

· FAN-driven power source : 15, 16

• NO. 1, 2 : RS485 Communication connection port

• NO. 3, 4 : Channel 1 4

-

20 mA d.c. input

• NO. 5, 6 : Channel 2 4

-

20 mA d.c. input

• NO. 7, 8 : Channel 3 4

-

20 mA d.c. input

• NO. 9, 10 : Alarm1 caution

"caution" The alarm is not a serious problem, but it is an alarm that needs to

be checked by the user due to abnormal symptoms. At this time, the TPR

output will go out to normal and only the alarm will be output.

·Caution error : partial load disconnection, heat sink overheat (60 ℃),

overcurrent, power failure, fuse disconnection, FAN error

• NO. 11, 12 : Alarm2 warning

If a "Warning" alarm can cause damage to the product and the load, a

warning will be issued in the following emergency situations. At this

time, the TPR will stop the output itself.

·Warning error : Heat sink overheat (80 ℃), SCR conduction (Short)

※ Once it enters the normal state by supplies of circuit power ( 100 ~ 240

V a.c. ) and load power, the alarm relay is short-circuited and it is

opended when alarm occurs. ("B" contact normally close) In case of

using "A" contact, inquire separately

※ If an alarm condition occurs, an alarm is output after 3 seconds, and

if the alarm condition is released within 3 seconds, an alarm No output.

■ Connection diagram of signal and alarm terminal

*OQVU

*OQVU

*OQVU

▍Installation panel cutout

■ 40/55/70 A

▍Part name and function

[Unit : mm]

■ 90 A

■ 130/160 A

LED indicator

name

Description

POWER

POWER indicator is ON when the power is being supplied to the control unit

CH1

Lights up when an alarm related to channel 1 occurs.

CH2

Lights up when an alarm related to channel 2 occurs.

CH3

Lights up when an alarm related to channel 3 occurs.

L.L

• When the heater is configured in parallel with the partial heater disconnection function, at least one of them is disconnected

This function is to maintain the process while detecting the heater disconnection.

• Detectable when using less than 3 parallel heaters. (In case of 4 or more parallel configurations)

• The total load capacity is not detected within the range of less than 6 A and 0 to 20 %.

• Part heater disconnection detection operation method (scan function)

- Corresponds to phase control, variable cycle control

- After circuit and load power supply is turned on, the LL LED flashes 0 to 100% The heater value is detected while sequentially

outputting the output.

- If the initial scan function is used only once after connecting the heater, the value stored in the internal CPU Therefore, no

further operation is required in the future.

- If you do not use the scan function and leave the initial mode 2 ON, Partial heater disconnection function is activated.

It is not precise in the way that it is detected by calculation formula automatically.

OT

• The LED flashes when the heat sink temperature rises above 60 ° C during control, Operation is normal, and if the

heatsink temperature drops below about 50 °C Will be released.

• If the heat sink temperature rises above 80 ° C during control, the LED will light up and TPR output will stop.

O.C

• When an overcurrent occurs, it will light up if a current above a set value is generated to protect the product and load,

Operation stop (can be set by communication)

• FAN failure: Flashing when FAN fails

EMG

EMG LED lighting situation is as follows.

1. Power failure: The load power is turned on when the circuit powe (100

-

240 V a.c.) is applied Lights when the

heater is disconnected.

2. SCR short: When SCR is shorted, the power is on without control input and TPR output Since the heater continues to

overheat, the current continues to flow without the control input. The EMG LED flashes when it flows. (10 A or more)

■ LED indicator and explanation

Number

OFF

ON

Initial setup MODE

No. 1

-

RESET (Functioning stops)

1. Input mode : 4

-

20 ㎃ d.c.

2. Control Mode: Phase control

No. 2

load volume scan

Partial load disconnection function

No. 3

Restart mode

Not Using

No. 4

-

cycle control fixed cycle method

No. 5

cycle control variable cycle method

No. 4, 5

Phase control

No. 6

Not Using

No. 7

3 channel function fixed

use all 1, 2, 3 channels

No. 8

-

4

-

20 mA d.c.

No. 7, 8

Check 8 LED lights

-

■ Internal dip switch operation

■ Fixed cycle control

As setting the constant cycle of the output, fixed cycle control

is to control the AC power supply repeatedly with a constant

rate of ON/OFF according to the control input.

■ Variable cycle control

Without setting a constant cycle, variable cycle control is to

control AC power supply with using the number of cycle.

■ Phase control

Phase control is to control the AC power supply

applied to the load proportionally according to

the control input signal as changing phase angle

(0 ~ 180 degree) in a each half cycle, 8.33 ms.

0/

0VUQVUDPOUSPM

0''

0/

0''

0/

0''

0/

0''

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0VUQVUDPOUSPM

$POUSPM

0VUQVU

$POUBDU

TJHOBM

$POUSPM

$POUSPM

$POUSPM

0/

0VUQVUDPOUSPM

0''

0/

0''

0/

0''

0/

0''

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0VUQVUDPOUSPM

$POUSPM

0VUQVU

$POUBDU

TJHOBM

$POUSPM

$POUSPM

$POUSPM

0/

0VUQVUDPOUSPM

0''

0/

0''

0/

0''

0/

0''

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0/

0''

0VUQVUDPOUSPM

0/

0''

0VUQVUDPOUSPM

$POUSPM

0VUQVU

$POUBDU

TJHOBM

$POUSPM

$POUSPM

$POUSPM

Example (ASCⅡ)

Division Address(ID) Function

Start Address

No. of Data

LRC

END

Request 0x01 0x31 0x03 0x33 0x30 0x30 0x30 0x31 0x30 0x30 0x30 0x31 0x46 0x41 0x0D 0x0A

Division Address(ID) Function

No. of

Data

Data

LRC

END

Response 0x30 0x31 0x30 0x33 0x30 0x32 0x30 0x30 0x30 0x30 0x46 0x41 0x0D 0x0A

Protocol MODBUS

RTU

MODBUS

ASCII

Speed

2400, 4800, 9600,

19200 bps

Parity

Even

None

Data bit

8

7

Stop bit

1

1

ID

1 ~ 31

BOLD : RAM DATA

READ

monitoring

READ/WRITE

Configurable

Communication MAP

PROCESS

INFO

CAL

Address

0

100

200

0

System

Scan Start

1

AlarmStatus

Scan Out Mode

2

CH1 Status

CH1 Complete

3

CH2 Status

4

CH3 Status

CH1 LL Rate

5

Rev

CH2 Complete

6

Soft Time

Out Mode

7

CH2 LL Rate

8

CH1 Output

CH3 Complete

9

CH1 Current

10

CH2 Output LL Use Mode

CH3 LL Rate

11

CH2 Current

Protocol

12

CH3 Output

BPS

13

CH3 Current

Parity

14

CH1 Input

Stop Bit

15

CH2 Input

Data Length

16

CH2 Input

Address

17

R.Time

18

CH1 Enable

19

CH2 Enable

20

CH3 Enable

21

CH1 Power Limit

22

CH2 Power Limit

23

CH3 Power Limit

24

CH1 OC Limit

25

CH2 OC Limit

26

CH3 OC Limit

Explanation by address

Process (0 ~ 99)

Address Parameter

Explanation

Setting range

Unit

1

AlarmStatus

Alarm status information

Refer to Bit Information

2

CH1 Status

CH1 Status information

Refer to Bit Information

3

CH2 Status

CH2 Status information

Refer to Bit Information

4

CH3 Status

CH3 Status information

Refer to Bit Information

5

-

-

-

-

6

Soft Time

Soft start Setting time

0 ~ 60

sec

7

-

-

-

-

8

CH1 Output

SCR CH1 Yield

0 ~ 100

%

9

CH1 Current SCR CH1 Load current value 0 ~ CT (max) (x10) A

10

CH1 Output

SCR CH2 Yield

0 ~ 100

%

11

CH1 Current SCR CH2 Load current value 0 ~ CT (max) (x10) A

12

CH1 Output

SCR CH2 Yield

0 ~ 100

%

13

CH1 Current SCR CH2 Load current value 0 ~ CT (max) (x10) A

14

CH1 Input CH1 4 - 20 mA Control signal input

0 ~ 100

%

15

CH2 Input CH2 4 - 20 mA Control signal input

0 ~ 100

%

16

CH3 Input CH3 4 - 20 mA Control signal input

0 ~ 100

%

Calibration (200 ~ 299)

Address

Parameter

Explanation

Setting range

Unit

200

Scan Start

Partial load disconnection scan

0 : Operating, 1:LL Scan

201

Scan Out Mode

Control mode for partial

load disconnection scan

0 : phase control 1 : fixed cycle cycle control

2 : Variable cycle cycle control

202

CH1 Complete

CH1 heater value saved

control, 2 : Variable cycle cycle control

204

CH1 LL Rate

CH1 Parallel heater breaks

1 ~ 6

EA

205

CH2 Complete

CH2 heater value saved

0 : No scan data, 1 : Complete

207

CH2 LL Rate

CH2 Parallel heater breaks

1 ~ 6

EA

208

CH3 Complete

CH3 heater value saved

0 : No scan data, 1 : Complete

210

CH3 LL Rate

CH3 Parallel heater breaks

1 ~ 6

EA

Infomation (100 ~ 199)

Address

Parameter

Explanation

Setting range

Unit

100

System

SCR Product Setup Status

0x0130 : TPR3SLEP

101

-

-

102

-

-

103

-

-

104

105

Rev

SCR Revision

106

Out Mode

Control method setting status

0 : phase control 1 : fixed cycle cycle control

2 : Variable cycle cycle control

110

LL Use Mode

Whether the partial heater

break function is used

0 : Disable partial heater disconnection function

1 : Using partial heater disconnection function

111

Protocol

Protocol setting status

2 : ASCII, 3 : RTU

112

BPS

Communication speed setting status

0 : 2400, 1 : 4800, 2 : 9600, 3 : 19200

113

Parity

Parity bit setting status

0 : None, 1 : Odd, 2 : Even

114

STOP BIT

Stop bit setting state

1, 2

115

DATA LENGTH

Data length

7, 8

116

ADDRESS

ID (SCR communication number)

1 ~ 31

117

R.TIME

Response time

0 ~ 10

118

CH1 Enable

Decide whether to use CH1

0 : Do not use this channel

1 : Use this channel

119

CH2 Enable

Decide whether to use CH2

120

CH3 Enable

Decide whether to use CH3

121

CH1 Power Limit

CH1 output limit setting

0 ~ 100

%

122

CH2 Power Limit

CH2 output limit setting

0 ~ 100

%

123

CH3 Power Limit

CH3 output limit setting

0 ~ 100

%

124

CH1 OC Limit

Set CH1 overcurrent value

0 ~ CT (max)

(x10) A

125

CH2 OC Limit

Set CH2 overcurrent value

0 ~ CT (max)

(x10) A

126

CH3 OC Limit

Set CH3 overcurrent value

0 ~ CT (max)

(x10) A

BIT Information

Parameter

AlarmStatus

CH1 Status

CH2 Status

CH3 Status

Address

1

2

3

4

Bit 0

-

Power Fail

Power Fail

Power Fail

Bit 1

FAN Fail

LL Fail

LL Fail

LL Fail

Bit 2

OC Fail

OC Fail

OC Fail

OC Fail

Bit 3

LL Fail

SCR Short

SCR Short

SCR Short

Bit 4

Over Temp 60

-

-

-

Bit 5

Over Temp 80

-

-

-

Bit 6

SCR Short

-

-

-

Bit 7

Power Fail

-

-

-

Bit 8 ~ 15

-

-

-

-

* 200: If it is 1, the status is being scanned. 0 is displayed after scanning is completed (3 channels are scanned at the same time)

* 201: Control method setting status being scanned

* 202: If it is 1, the scan is completed and the heater value is stored in the internal storage device (If it is 0, it is not saved, not scanned)

* 204: Set to 3 for 3 heaters (Low load malfunction concern Output 20% or less Detection prohibited)

M3.5

M6

M8

M6

M3.5

M8

M8

M6

M3.5

26.0

15.0

7.3

• 90/130/160 A

Explanation about SCR Alarm

Alarm (LED) Alarm Description

Checking list

Power Fail

(EMG

lighting)

When load power is

not applied

1. Confirmation of load power voltage for each channel

(Example: Check 1CH load voltage when 1CH POWER Fail)

2. Check that the load power breaker is ON (Reset, turn on / off)

3. SCR load power input terminal R, S, T wiring check

Fuse disconnected 1. Open the upper case of SCR and check the fuse disconnection

(Shot is normal when measuring the fuse tester after the load power is turned off)

When the heater is

disconnected

1. Check the resistance value of the load connected to the SCR (disconnection and disconnection)

2. Check the SCR heater connection terminals U, V, W wiring

SCR Short

(EMG

flashing)

Internal SCR

element shorted

1. Symptom: When 4 mA and control input are not applied, load current When more than 5 A flows.

2. Confirm: Check several channel SCR Short

3. Generation channel 4

-

20 mA Input part voltage is less than 0.4 V, Ensure current is measured in

clampmeter (SCR failure if confirmed, replacement required)

OC Fail

(OC lighting)

In case of

overcurrent

1. When the current exceeding the OC Limit setting value flows to the load

2. Clamp meter connected to overcurrent identified channels U, V, W Check the current on the wiring.

Fan Fail

(OC flashing)

FAN failure

1. Make sure that the cooling fan on the bottom of the SCR is rotating

2. Make sure that there is foreign substance in the cooling fan

LL Fail

(LL lighting)

One or more

disconnection in

parallel heater

configuration

1. Check if the heater value is saved using the Scan function (communication)

2. If you do not know whether or not you have scanned the control signal (4

-

20 mA)

When there is no scan, DIP SW 2 turns OFF and scan progress, LL LED

When it changes to flashing, it changes to switch ON position again.

3. Check the resistance value of the heater. Comparison of the resistance value of the part

(When the resistance value becomes high)

Over Temp 60

(OT flashing)

Heat sink temperature

Over 60 degrees

1. Check if cooling fan is rotating well

2. Identify the cooling unit inside the panel

3. If an alarm occurs immediately upon power

-

on, the SCR internal fault.

Over Temp 80

(OT lighting)

Heat sink temperature

Over 80 degrees

4FQBSBUFQPXFS

JOQVUUFSNJOBM

4JHOBMBOE

BMBSNUFSNJOBMT

-&%EJTQMBZ

4PGUTUBSUPS

61%08/TFUUJOHWPMVNF

*OUFSOBMEJQTXJUDI

$PNNVOJDBUJPOEJQTXJUDI

-PBEUFSNJOBM

※ The reset operates after turning off the switch 1 and turning it on again through the CPU reset

● SOFT

This is the function to set the soft start and soft up/down times.

(Set via external VR)

- Soft start : It is a function to protect against load with large starting current

(inrush current) and it gradually increases output operates when power is

turned on while control input is applied, and is set to 50 seconds at

maximum VR. (ex : 20 mA : 50 seconds,, 12 mA : 25 seconds,)

- If VR is set to the minimum, this function does not work, and the time is

reduced as VR is changed to the left.

Function to protect power regulator (TPR) and load when overcurrent occurs.

(Phase control only)

- At the time of shipment, it is set to about 120 % of the product rating, and the

overcurrent detection setting value can be changed through communication.

It is a function to limit the output separately from the control input signal. It

can be set through communication and the maximum output amount is

limited according to the set value.

- Set to 100 % at the time of shipment

■ VR Explanation

■ O.C

■ Output limit function