Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

10

Troubleshooting

What to do if:

The chipper

won’t start

•

The engine oil level might be too low

The chipper is fitted with oil alert and will not start if the oil level is too low

Check the oil level and top up if required

•

The chipper is placed on a slope

The chipper is fitted with oil alert and will not start if the oil is not level

Move the chipper to level ground

Belt drive engagement will not work

•

The housing might be blocked

Turn engine off, disconnect the spark plug wire, ensure rotor has completely stopped, remove debris,

restart engine, then attempt to re-engage the belt drive

Drive belts squealing/smoking

•

Drive belts are loose/damaged

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped. Follow the

belt tensioning procedure on page 15

Discharge slows down

•

The chipper is clogged up

Turn the engine off, disconnect the spark plug wire, ensure rotor has completely stopped, remove debris,

then close and lock the outlet chute

Outlet chute is blocked

Outlet is pasted with wet/leafy material

Feed hard, dry material in with softer material

Turn the engine off, disconnect the spark plug wire and ensure rotor has completely stopped. Open up

the outlet chute and clear blockage.

The material is ejected in long strips

•

The knives and/or anvil might be blunt

Once the engine has been given enough time to slow

down to idle speed (about 10-15 seconds), disengage the

rotor by winding the engagement handle in the counter

clock-wise direction until the handle comes to a stop.

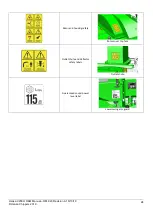

WARNING!

Only engage and disengage the rotor at

idle speed otherwise excessive vibration and belt friction

may cause damage.

Allow the engine to cool down by running at idle for at

least 1

–

2 minutes before shutting down. Turn the

ignition key anti-clockwise into the off position to shut

the chipper down.

WARNING!

The heavy rotor will continue to turn for

some time after the engine has been shut down. Do not

open the rotor housing cover until the engine and cutting

disk have completely stopped and the rotor is

disengaged.

2

3