69

SafetyandImportantInformation

Hansgrohe products are safe provided they are installed,

used and maintained in accordance with these instructions

and recornrnendations.

Please read these instructions thoroughly and retain for

future use.

The plumbing installation of this thermostat mixing

valvemust comply with the requirements of UK

Water Regulations/Bylaws (Scotland), Building Regulati-

ons or any other regulations specified by the local Water

Authority and supplier.

The installation of thermostatic mixing valves must comply

with the requirements of the Water Supply (Water Fittings)

Regulations 1999.

We strongly recommend that you use a plumber registered

with or a member of an Association:

Chartered Institute of Plumbing and Heating Engineering

(CIPHE)

Water Industry Approved Plumber Scheme (WIAPS)

Dispose of plastic bags carefully

Keep children well away from the work area.

Check for hidden pipes and cables in the wall before

drilling holes.

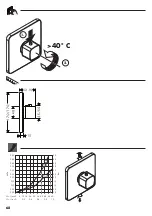

The unit must be mounted on a finished waterproofed wall

surface (usually tiles).

If you are using power tools (e.g. to drill holes) wear sa-

fety glasses and always disconnect tools from the power

supply after use.

Do not operate the shower unit if the hand shower or spray

hose has been damaged or is blocked.

Do not block the flow of water from the hand shower, by

placing it on your hand or any other part of your body

or foreign object.

The thermostatic unit should be serviced annually by a

qualified person to ensure maximum safety during use.

The mixer is fitted with check valves (page 67 pos.

97350000). There are filters on the thermostatic element

too (page 67 pos. 96633000).

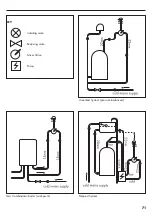

The fitting of isolation valves is required (preferred location

page 70 Installation Requirements)

Onthefollowingpages68-73youcan

findimportantinformationonlyforthe

installationinUK

TechnicalHotlineforUKonly

08707701975

E-mailforUKonly

(Diese Servicehotline ist nur für das Vereinigte König-

reich Großbritannien, nicht z. B. für Deutschland)

Содержание Axor Urquiola

Страница 24: ...1 MPa 0 1 0 5 MPa 1 6 MPa 1 MPa 10 bar 147 PSI 80 C 65 C 70 C 4 64 DIN EN 1717 62 62 42 66 68 24...

Страница 25: ...68 0 3 MPa 67 68 MTC 42 C 65 C 180 180 60 25...

Страница 27: ...68 0 3 67 68 42 65 180 60 27...

Страница 43: ...68 0 3 MPa 67 68 42 C 65 C 180 180 60 43...

Страница 55: ...68 0 3 67 68 42 C 65 C 180 180 60 55...

Страница 58: ...68 0 3 67 68 42 65 180 180 60 58...

Страница 59: ...1 0 5 0 1 1 6 PSI 147 10 1 80 C 65 C 4 70 C 64 DIN EN 1717 DIN 1988 62 62 42 66 68 59...

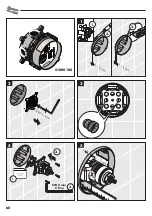

Страница 60: ...60 1 2 mm X Montage 2 1 2 2 SW 4 mm 5 Nm 3 4 5 1 01800180 1 2 3...

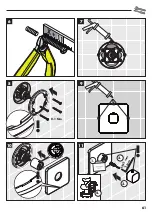

Страница 61: ...61 Montage 3 4 S W 3 m m 2 N m 2 1 7 6 8 9 10 11 X 11 0 1 Nm...

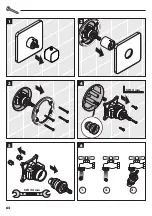

Страница 62: ...62 Safety Function Justierung 2 1 3 1 1 2 S W 3 m m 2...

Страница 63: ...63 z B 42 C for example 42 C 2 1 1 2 3 4 5 6 7 8 S W 3 m m 2 N m 1 2...

Страница 64: ...64 Wartung 1 2 3 2 3 4 5 6 SW 24 mm SW 4 mm 1...

Страница 65: ...65 Wartung 2 1 8 9 10 11 12 SW 24 mm 15 Nm SW 4 mm 5 Nm 7...

Страница 67: ...67 Pr fzeichen P IX DVGW SVGW ACS WRAS ETA KIWA 11731000 P IX 18019 II BQ0587 X X X X DIN 4109 P IX 18019 II...

Страница 75: ...75...