26

w

e

e

z

Turn the power switch off. Lower the presser

foot. Turn the needle clamp screw

q

counterclockwise with the large screwdriver.

Loosen the screw and remove the needle from

the needle clamp.

q

Needle clamp screw

To determine if the needle is defective, place the flat side of

needle on something flat (a needle plate, piece of glass, etc.). The

gap between the needle and the flat surface should be consistent.

Never use a blunt or blunt needle, as it may cause skipped

stitches or thread breakage. Defective needles can ruin the fabric.

Always purchase good quality needles. Change needles often.

Needle (HL x 5) size

9 or 11

11 or 14

14, 16 or 18

Light weight

Medium

weight

Heavy weight

Fabrics

Crepe de chine,

Voile, Lawn,

Organdy, Geor-

gette, Tricot

Linens, Cotton,

Pique, Serge,

Double Knits,

Percale

Denim, Tweed,

Gabardine,

Coating, Drapery

and Upholstery

Fabric

Thread

Fine silk

Fine Cotton

Fine Synthetic

Covered Polyester

50 silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton Covered Polyester

50 silk

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester

Thread and Needle Chart

z

x

q

x

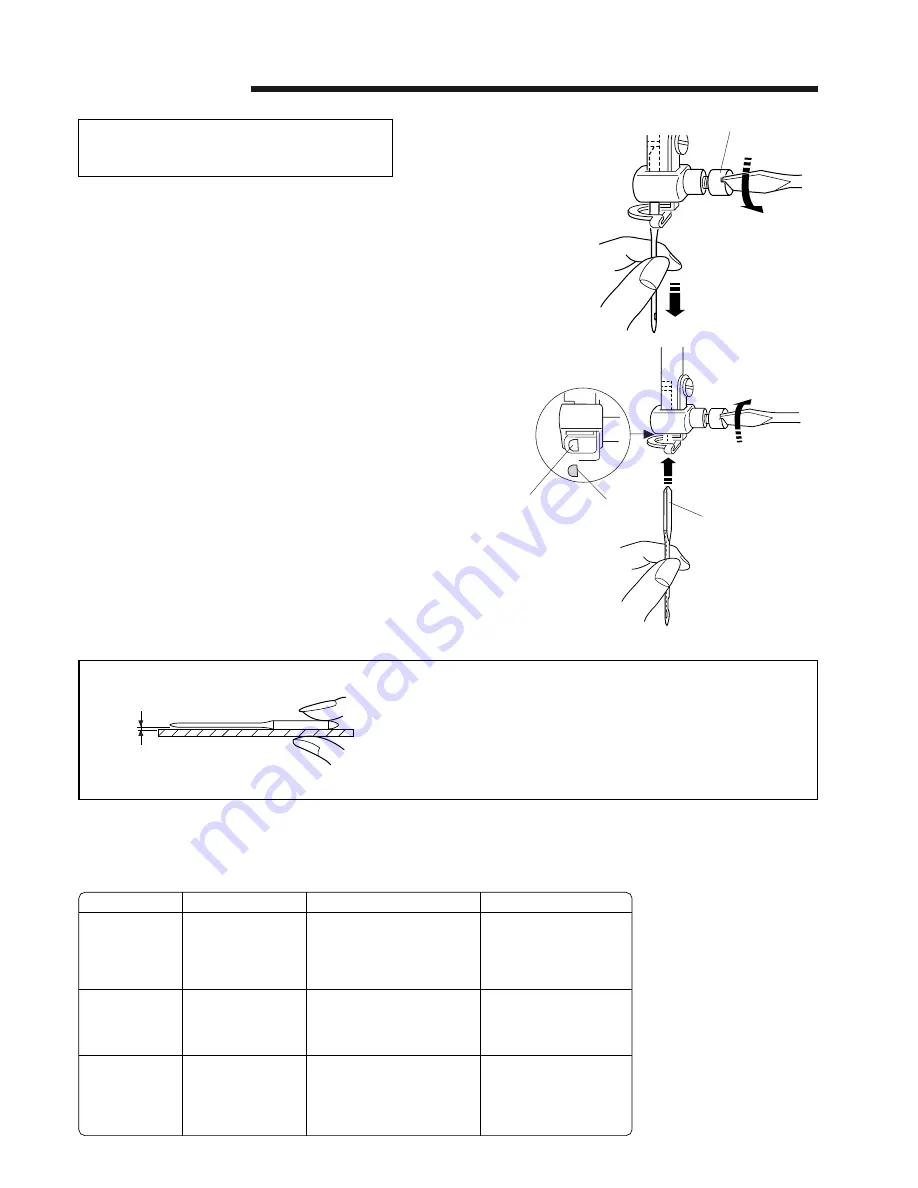

Insert a new needle into the needle clamp

w

with the flat side

e

to the right, pushing it up

as far as it will go.

Tighten the clamp screw

q

firmly.

w

Needle clamp

e

Flat side

* Use an HL x 5 needle

Changing the Needle

CAUTION

Turn the power switch off and unplug the

machine before changing the needle.

To Check the Needle