HAMWORTHY HEATING LTD

SHERBORNE

500001103/E

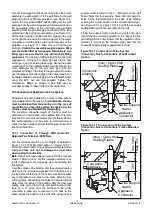

6.7 Surface Temperatures

Combustible materials in the vicinity of the boiler and

flue shall not exceed 65°C during boiler operation.

The flue shall not be closer than 50mm to any

combustible material, except where it passes through

such material with a non-combustible sleeve when the

air gap may not be less than 25mm.

6.8

Flue System Location

The flue system must not be placed or fitted where

there is undue risk of accidental damage to the flue

pipe or undue danger to persons in the vicinity. Check

that the flue is clear from any obstruction.

7.0 AIR SUPPLY

Detailed recommendations for air supply and

ventilation requirements are given in

BS 6644

, and

BS 5440:Part 2

. The following notes are intended to

give general guidance. In all cases there must be

provision for an adequate supply of air for both

combustion where applicable, and general ventilation,

in addition to that required for any other appliance.

7.1

Air Supply By Natural Ventilation

(Open-flue installation only)

The boiler room must have, or be provided with,

permanent air vents directly to the outside air, at high

level and at low level. For an exposed boiler house,

air vents should be fitted preferably on all four sides,

but at least on two sides. Air vents should have

negligible resistance and must not be sited in any

position where they are likely to be easily blocked or

flooded or in any position adjacent to an extraction

system which is carrying flammable vapour. Grilles or

louvres must be so designed that high velocity air

streams do not occur within the space housing the

boiler.

The air supplied for boiler house ventilation shall be

such that the maximum temperatures within the boiler

house shall be as follows:

1) At floor level (or 100mm above floor level) = 25°C.

2) At mid-level (1.5m above floor level) = 32°C.

3) At ceiling level (or 100mm below ceiling level) = 40°C.

Where both low and high level openings are used, the

grilles shall have a total minimum free area of :-

Low Level - (inlet)

550cm

2

per boiler.

High Level - (outlet)

275cm

2

per boiler.

7.2

Air Supply (Room-sealed installation)

If the Sherborne boiler is installed as a room-sealed

boiler

within a room

there is no requirement for the

room to have additional ventilation.

If the Sherborne boiler is installed as a room-sealed

boiler

within a cupboard or compartment

, the

enclosure shall be provided with both high and low

level air vents sized in accordance with the following.

Figure 7.2 Minimum Air Vent Requirements per

Boiler Installed in a Compartment

Vent position

Room or inter-

nal space

Direct to out-

side air

cm

2

/boiler

cm

2

/ boiler

High level

700

350

Low level

700

350

Compartment ventilated to:

7.3 Air Supply By Mechanical Ventilation

(Open-flue installation only)

Air supplied to the boiler room by Mechanical means

should be as follows :-

1)

Mechanical inlet and mechanical extract can be

utilised providing the design extraction rate does not

exceed one third of the design inlet rate.

2)

Mechanical extract ventilation with natural inlet

ventilation

MUST NOT

be used.

NOTE:

For Mechanical ventilation systems an

automatic control should be provided to cut off the gas

supply to the boiler, in the event of failure of air flow in

either inlet or extract fans.

Figure 7.3 Mechanical Ventilation Flow Rates

…. (Open flue installation only)

Forced / in-

duced

Flow rate per 1000kW

total rated heat input (Gross)

Inlet air

(Combustion

ventilation)

Extract air

(ventilation)

m³/s.

m³/s.

Volume

0.90

0.60

8.0

WATER CIRCULATION SYSTEM

8.1 General

The Sherborne boiler

has a low water content and

the requirements of minimum water flow are given in

Section

8.8: Minimum Water Flow Rates

and

Figure 2.2. Recommendations for the water

circulation system are given in

BS 6644

and

CP

342

. The following notes are of particular

importance:-

1)

In a combined central heating and hot water

system, the hot water storage vessel must be of the

indirect cylinder or calorifier type. The hot water

storage vessel should be insulated preferably with

not less than 75mm (3 in) thick mineral fibre, or its

thermal equivalent.

2)

Circulating pipework not forming part of the useful

12

Содержание Sherborne S65

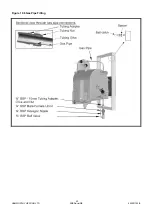

Страница 8: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 1 1 Boiler Installation Typical 2 ...

Страница 29: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E Figure 10 6 Gas Pipe Fitting 23 ...

Страница 45: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 39 ...

Страница 46: ...HAMWORTHY HEATING LTD SHERBORNE 500001103 E NOTES 40 ...

Страница 47: ...Notes ...