035-17477-002 Rev. D (1202)

Unitary Products Group

3

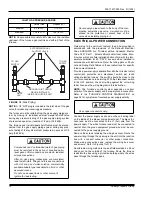

VENT SAFETY CHECK PROCEDURE

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while

any other appliances connected to the venting system are not

in operation:

1.

Seal any unused openings in the venting system.

2.

Inspect the venting system for proper size and horizontal

pitch, as required in the National Fuel Gas Code, ANSI

Z223.1, or the CAN/CGA B149 Installation Codes and

these instructions. Determine that there is no blockage

or restriction, leakage, corrosion or other deficiencies

which could cause an unsafe condition.

3.

Insofar as is practical, close all building doors and win-

dows and all doors between the space in which the appli-

ance(s) is located and other spaces of the building. Turn

on clothes dryers. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they shall oper-

ate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4.

Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so the

appliance shall operate continuously.

5.

Test for draft hood equipped appliance spillage at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

6.

After it has been determined that each appliance con-

nected to the venting system properly vents when tested

as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning appliance

to their previous conditions of use.

7.

If improper venting is observed during any of the above

tests, the venting system must be corrected.

8.

Any corrections to the common venting system must be

in accordance with the National Fuel Gas Code Z223.1

or CAN/CGA B149.1 or .2 Installation Code (latest edi-

tions). If the common vent system must be resized, it

should be resized to approach the minimum size as

determined using the appropriate tables in Appendix G

of the above codes.

SPECIFIC UNIT INFORMATION

LIMITATIONS & LOCATION

This furnace should be installed in accordance with all

national and local building/safety codes and requirements, or

in the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 or CAN/CGA B149.1 or.2 Installation

Code (latest editions), local plumbing or waste water codes,

and other applicable codes.

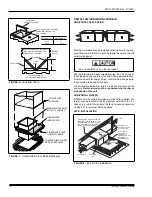

Downflow/horizontal models when installed in a downflow

configuration are AGA/CGA listed for application into a manu-

factured (mobile) home.

Upflow models or horizontal applications are not approved for

mobile homes.

CLEARANCES FOR ACCESS

Ample clearances should be provided to permit easy access

to the unit. The following minimum clearances are recom-

mended:

1.

Twenty-four (24) inches between the front of the furnace

and an adjacent wall or another appliance, when access

is required for servicing and cleaning.

2.

Eighteen (18) inches at the side where access is

required for passage to the front when servicing or for

inspection or replacement of flue/vent connections.

In all cases, accessibility clearances shall take precedence

over clearances for combustible materials where accessibility

clearances are greater.

This furnace may not be common vented with any

other appliance, since it requires separate, prop-

erly-sized air intake and vent lines. The furnace

shall not be connected to any type of B, BW or L

vent or vent connector, and not connected to any

portion of a factory-built or masonry chimney.

If this furnace is replacing a common-vented fur-

nace, it may be necessary to resize the existing

vent line and chimney to prevent oversizing prob-

lems for the new combination of units. Refer to the

National Gas Code (ANSI Z223.1) or CAN/CGA

B149.1 or .2 Installation Code (latest editions).

Do not install the furnace in an unconditioned

space or garage that could experience ambient

temperatures of 32° F (0° C) or lower. For applica-

tion in below freezing locations, See “BELOW

FREEZING LOCATIONS” on page 4.

The furnace is not to be used for temporary heat-

ing of buildings or structures under construction.

This unit must be installed in a level (1/4”) position

side-to-side and front-to-back to provide proper

condensate drainage.

Do not allow return air temperature to be below

55°F for extended periods. To do so may cause

condensation to occur in the main fired heat

exchanger.

Only use natural gas in furnaces designed for nat-

ural gas. Only use propane (LP) gas for furnaces

that have been properly converted to use propane

(LP) gas. Do not use this furnace with butane.

Using wrong gas could create a hazard, resulting

in damage, injury or death.