MULTIPLE FURNACES IN COMMON DUCT WORK

Multiple furnaces connected to common duct work, either supply, return, or both supply

and return must be wired so that all furnace blower motors are energized at the same time.

WARNING

Failure to turn all blowers on at the same time can cause a reversal of air flow in those units where the

blower motor is not operating. This reversal of air flow can cause premature blower, blower motor,

wiring and or heat exchanger failure.

Please consult the factory for specific wiring instructions for your application.

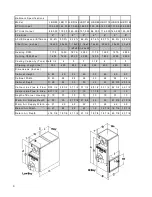

Table 6 Blower Specifications

Model HP

Speeds

RPM

Volts

Full

Load Amp.

Rotation Blower

Model

HBD/LBD 85

3/4

Variable

1400 Max

115

9.6

CCW

100-10T

HBD/LBD 115

3/4

Variable

1400 Max

115

9.6

CCW

100-10T

ECM MOTOR OPERATING MODES

Introduction

The ECM 2.3 motor is a variable speed, high effiency motor which has the ability to produce constant

air flow within a system, independent of static pressure. It achieves constant air flow by adjusting

speed and torque to account for changes in system static pressure. The GE ECM uses a proprietary

mathmatical algorithim to model air moving systems driven by forward curved blower wheels.

Operating Modes

The ECM motor is controlled by 24VAC thermostat signals to determine which mode of operation the

blower is to run. Air flow rates in the different modes are controled by the setting of the DIP

switches.

Standby Mode:

The thermostat inputs are being continuously monitored . The motor will respond to the 24

volt AC input signal from the thermostat.

Fan Mode:

When a call for fan operation is received from the thermostat (“G” line is energized) the

blower will operate at a reduced speed as determined by the position of the cooling DIP

switches as set for the airconditioning speed. See air flow tables for DIP switch and air flows.

If a call for cooling or for heating is energized along with the call for fan only the unit will run

at the respective air flow for heating or cooling.

Cooling Mode:

When a call for cooliong is received from the thermostat (“Y” line is energized) the motor will

operate at the cooling speed and profile as adjusted by the cooling DIP switches. Cooling air

flow is profiled to ramp the air flow up to the full cooling air flow to allow for maximum

dehumidification

Heat Mode:

When a call for heat is received from the thermostat (“W” line is energized) the motor will

operate through the heating cycle at the air flow as adjusted by the heating DIP switch. When

a call for heat is initiated the blower will turn on after a 90 second delay to ensure warm

plenum temperatures as the furnace heats up. The blower then runs at a reduced rate for 3-1/2

minutes before increasing its speed to the full air flow requireements.

9

Содержание HBD1 15

Страница 17: ...17 17...

Страница 31: ...31...