EtherNet/IP adapter functionality

11

match those of the SMpdp module. Please note that the PLC can readout the actual size of the

process data configured inside the KE/SE from the diagnostics area (see reference section).

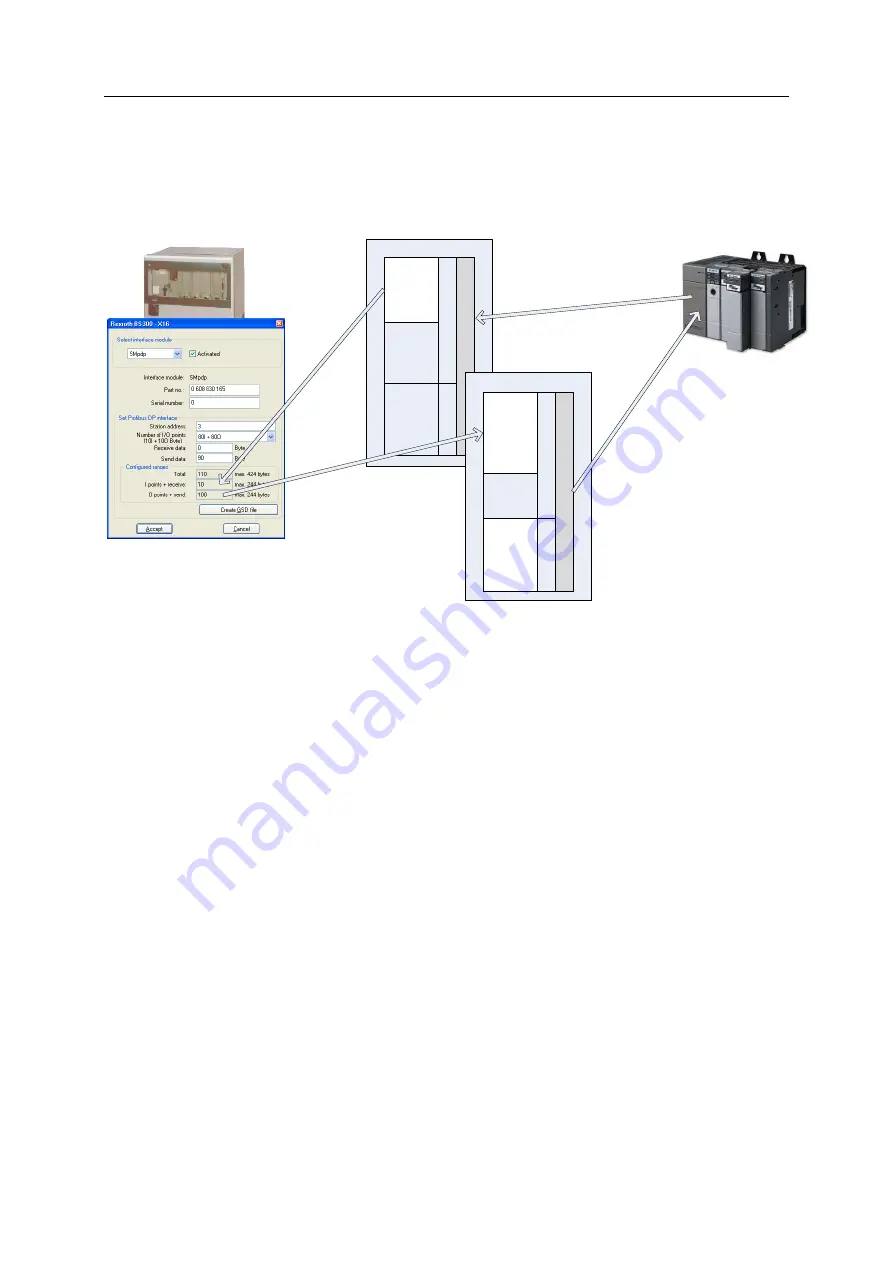

The following picture shows the data flow and data areas in an example case:

2

4

0

b

y

te

s

p

ro

c

e

s

s

d

a

ta

K

E

in

p

u

ts

(1

0

b

y

te

s

)

CIP object

1

4

4

u

n

u

s

e

d

u

n

u

s

e

d

3

8

4

b

y

te

s

C

IP

o

b

je

c

t d

a

ta

u

n

u

s

e

d

2

4

0

b

y

te

s

p

ro

c

e

s

s

d

a

ta

K

E

o

u

tp

u

ts

(1

0

0

b

y

te

s

)

1

4

4

d

ia

g

s

u

n

u

s

e

d

3

8

4

b

y

te

s

C

IP

o

b

je

c

t d

a

ta

P

ro

fib

u

s

d

ia

g

n

o

s

tic

s

CIP object

Read process data

(get assembly 103 data)

Write process data

(set assembly 103 data)

PLC

BG02-EIP

SE/KE

3.2.1

Input data (PLC

BG02

KE)

The process input data (data sent from PLC to BG02) is mapped into the lower 240 bytes of the

assembly object instance 103 attribute 3. This data is cyclically updated (every 20ms) by writing to

the Profibus Slave #3 (the KE/SE SMpdp interface). The PLC must always write 384 bytes.

3.2.2

Output data (KE

BG02

PLC)

As outlined above, the output data sent from BG02 to the PLC is made up of two blocks. The first

block contains process data read from the KE’s SMpdp Profibus module, the second contains

diagnostics data on the BG02

KE SMpdp Profibus communication. The second block always starts

at byte offset 240 (dez), as the maximum process data size allowed in the KE is 240 Bytes. The PLC

must always read a fixed size of 384 bytes, therefore reading both blocks of information.

The first block containing process data is a 1:1 copy of the process data received via the Profibus

interface from the SE/KE. This means all signal mapping is done inside the KE using the BS300

software by setting up the “PLC assignment table”.

The following table shows the layout of the diagnostics area. Note, that all values are encoded using

“intel” endianness (“little endian”, i.e. LSB is first in memory).