-13-

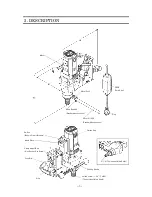

2.Checking and adjustment of Drill Carriage Assy.

(In case of combination with □49 Drill Carriage Assy.)

◎

Set Drill Head onto Pole Base. While moving

feeding handle, tighten 4 pieces of hex. socket set

screws on Drill Carriage Assy. in good balance

with hex. bar wrench and adjust the gap between

Pole and Drill Carriage Assy.

As for the degree of adjustment from

①

side,first

tighten hex. socket set screw till the rattling stops.

As for the degree of adjustment from

②

side, first

tighten hex. socket set screw till the rattling stops.

Then loosen them back by one quarter of one

turning.(When core drill is fixed on the floor, drill

head do not slide (fall) down because of its

weight.)

CAUTION

If hex. socket set screw are fastened too tight,

feeding handle gets heavy. When slide plate is

worn and starts to rattle, replace it.

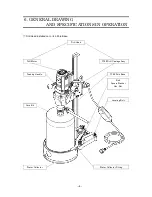

3. Checking and adjustment of clutch

◎

As Friction Plates wear out, the clutch becomes easy to slip. When this happens,

readjust the clutch using clutch adjusting tools.

1) Set the

speed

change at HI.

2) Remove Hex.

Socket

Cap Plug 1/8” from Gear Case by Hex. Bar Wrench (5mm).

3) Insert the tip of

Clutch

Adjusting Pin into the hole, where the plug 1/8” is removed,

in parallel with the main shaft. While doing this, slowly turn the Main Shaft by hand

and further insert Clutch Adjusting Pin till the Main Shaft is locked.

4) Hold Clutch Adjusting Pin by your hand, hang the Spanner 36mm on the Main

Shaft. Using Torque Wrench, fasten the clutch.

Model

Tightening

Torque

Tightening

Direction

SPZ-252U

2

i

72N

・

m

Left

CAUTION

Tightening more than specified value might

cause the damage to clutch adjusting pin and

Drill Motor.

①

②

Clutch Adjusting Pin

Torque Wrench

Hex. Bar Wrench

Spanner 36mm

Left

Right

Содержание SPZ-252U2i

Страница 19: ...17 MEMO...