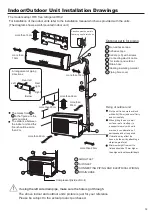

Outdoor Unit

25

Dirección: Parque Industrial Haier, Calle Qianwangang, Zona de Desarrollo Económico y Tecnológico, Qingdao 266555,

Shandong, R.P.C.

Contactos: TEL +86-532-88936943; FAX +86-532-8893-6999

Sitio web: www.haier.com

indoor

display

Contents of Malfunction

LED flash tim

e

S

of

PCB

Diagnosis and Analysis

F12

EEPROM ERROR

1

F1

IPM protection

2

Input over current occured been detected by PIM hardware

F22

AC overcurrent

protection

3

F3

Communication fault

4

Communication failure between outdoor board and module

●

F20

Press overload

5

Send from the module.

。

F19

Overvoltage or underv-

oltage protection

6

The voltage of P/N exceed or below the EE voltage limmit of

the module board.

F27

Press blovked/stoped

7

Send from the module,3 times within 30 minutes send to indoor board

F4

Discharging temp.senor

Td abnormal

8

After the press is started for10 minnutes,the Td temp.exceed the

temp. in EE.3 times within 30 minutes send to indoor board.

F8

DC fan motor fault

9

Error status confirm and lock if occurs 3 times within 30 minutes

F21

10

F7

11

Start up and test immediately

F6

12

F25

13

F30

The press suction tpmp.

is too high

14

After starting up 10 minnutes to test, for 5 minutes,the Ts temp.

was detected to be over

40℃,

then shut down compressor send to indoor

board.

●

Starting again in three minutes.

E7

Communication fault

15

Communication failure between indoor unit and outdoor unit

F13

Lack of refrigerant

16

The comressor runs continuously for more than 5 minutes and the

current value of outdoor unit is 0.6A-1.6A.Meet the cool/heat

●

conditions,flashing outdoor lights

F14

Four-way valve fault

17

Check the indoor unit coil temp.,after the heating compressor starts

up 10minutes,Tc≤

0℃

last on one minute,then stop the compressor.

Deforsting and deforsting exit will not be detected within 5 minutes

F11

Compressor out of step

18

From the module board

F28

Position detection

ioop fault

19

From the module board,Appear 3 times in 10 minutes and confirm

E9

Indoor overload shutdown

21

Compressor start up 2 minutes after the start of testing.If Tc≤

1℃

last on 2 minutes the compressor stop.When the compressorstops for

more than 3 minutes and Tc

>9℃,

the compressor resumes.

E5

Indoor anti-frost stop

21

F5

Module temperature is

too high(95?)

23

Module temperature is too high for protection.

F2

Compressor software

over current

24

From themodule board.1.35 times the total current.

F23

Phase current over current

25

If the phase current of the compressor is greater than the phase current

stop value in EE of the outdoor unit during runing,then compressor stop.

After 3 minutes compressor restart.

F24

CT of bolt

27

,

When the total current of the compressor is detected to be less than0.5A

and the compressor frequency is greater than 50Hz, theduration is one minute.

Then force the compressor to stop for 3 minutes,no fault confirmed

●

F34

External coil protection

37

F35

Module unknown fault

38

F36

Tcm resistance abnormal

39

●

F41

High pressure protection

43

F42

Low pressure protection

45

F43

Type matching exception

46

EEPROM chip damaged or data fault

The AC current value exceeds the total current stop value in

EE.Error lock if appear 3 times within 30 minutes.

Start up and test immediately

Start up and test immediately

Td resistance fault

Ta resistance fault

Ts resistance fault

Te resistance fault

After starting up 10 minnutes to test, 3 times within 30 minutes

send to indoor board.

Compressor start up 2 minutes after the start of testing.If Tc≥

63℃

last on 5 minutes the compressor stop.When the compressorstops for

more than 5 minutes and Tc

●

<39℃,

the compressor resumes

outdoor

Содержание 1U71S2SR2FA

Страница 2: ......

Страница 16: ...WARNING CAUTION N Open the window and well ventilated the room explosion proof fuse 13 ...

Страница 18: ...R32 2 3 R 2 3 R R32 R32 R32 R32 R32 15 ...

Страница 20: ...R32 R32 R32 R32 R32 R32 R32 R32 R32 17 ...

Страница 21: ...3 R32 R32 R32 R32 R32 R32 R32 18 ...

Страница 22: ...R32 R32 R32 R32 R32 R32 R32 R32 10A HFC 410A 19 ...

Страница 25: ...22 ...

Страница 26: ...23 R32 R32 ...