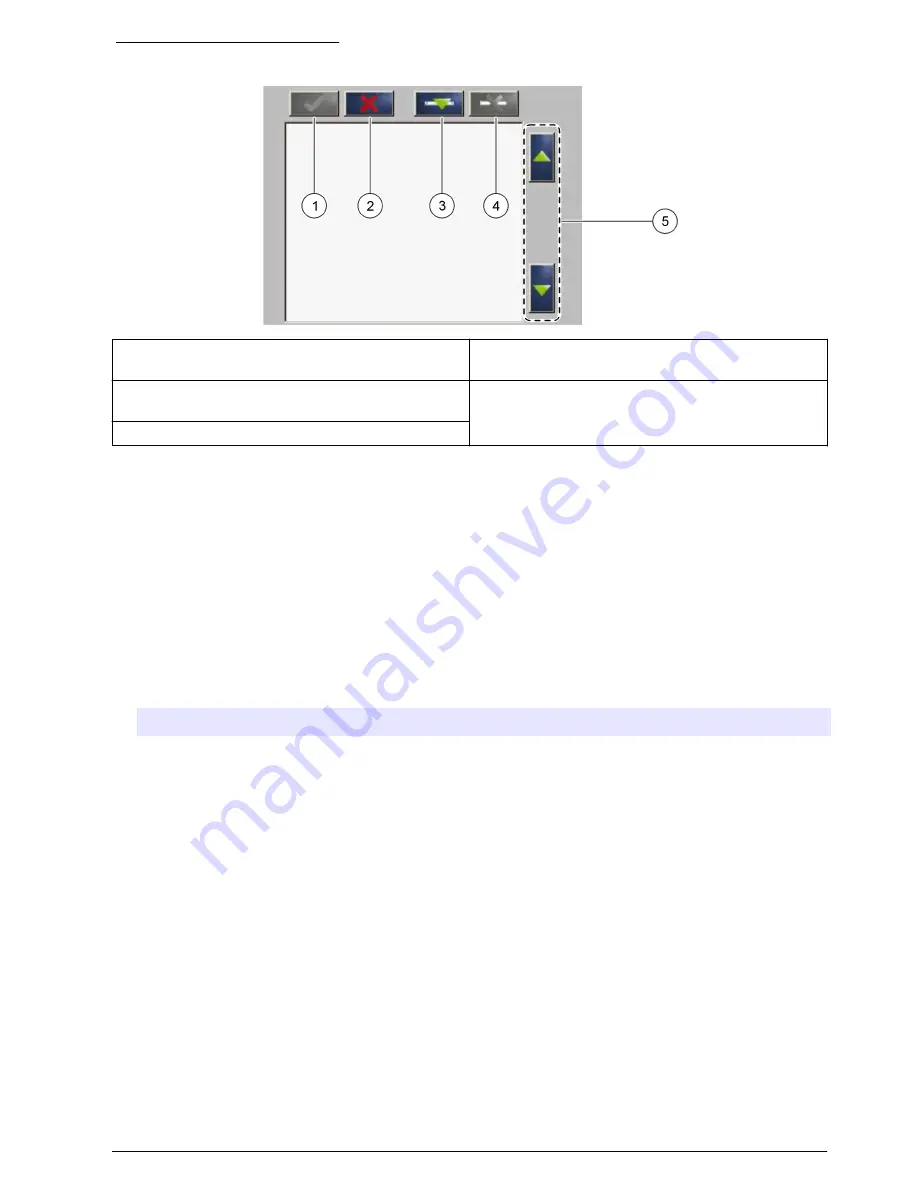

Figure 1 Keypad description

1

Enter: Saves the setting and exits the current

screen to the CONFIGURE menu

4

Delete: Removes a sensor from the selection

2

Cancel: Exits the current screen to the

CONFIGURE menu without saving the setting

5

UP and DOWN arrows: Moves the sensors up or

down the list

3

Add: Adds a new sensor to the selection

Startup

Add a sensor

Note: PROGNOSYS is not available for all sensors. Only newer sensor models can use the PROGNOSYS

function.

Note: Make sure that an RTC or a PROGNOSYS communication card is installed in the sc1000 sensor module.

When an RTC or PROGNOSYS communication card is installed, PROGNOSYS files are available

for different sc sensors. Do the steps that follow to add a sensor. Refer to

Figure 2

.

1.

Connect the controller. Refer to the controller documentation.

2.

Select an option.

Option

Description

For

RTC/PROGNOSYS

card

Select MAIN MENU>RTC MODULES/PROGNOSYS>RTC

MODULES>RTC>CONFIGURE>SELECT SENSOR

For PROGNOSYS

card

Select MAIN MENU>RTC

MODULES/PROGNOSYS>PROGNOSYS>CONFIGURATION>PROGNOSYS>SELECT

SENSOR

3.

Push

Add

. A list with all network connections opens.

4.

Select the applicable sensor for the RTC or PROGNOSYS module and push

Enter

. The sensor is

shown in the sensor list.

Note: Sensor names with black font are available for an RTC module. Sensor names with red font are not

available for an RTC module. A sensor name identified with a "(p)" is available for PROGNOSYS.

5.

Push

Add

to add more sensors from the list.

Sensors that are selected before are shown in gray. Refer to

Figure 3

on page 7 or

Figure 4

on page 7 to put in order or delete a sensor.

6.

Push

Enter

to accept the list.

English

5

Содержание PROGNOSYS

Страница 1: ...DOC023 52 90351 PROGNOSYS 05 2014 Edition 7 User Manual ...

Страница 2: ......

Страница 4: ...Table of Contents 2 ...

Страница 22: ...20 English ...

Страница 24: ......

Страница 25: ......