2

8. INSPECTION

The equipment must be inspected in accordance with the conditions of

use and the operating conditions at least once per year by an authorised

person 2 per TRBS 1203 (Technical expert) (testing per BetrSichV, §10,

sect.2 represents implementation of EC Directives 89/391/EEC and

95/63/EC and the annual occupational safety inspection per BGV D8,

§23, sect. 2 and BGG956). These inspections must be documented:

– Before commissioning.

– After significant alterations before recommissioning.

– At least once per year.

– In the event of unusual occurrences arising that could have detrimen-

tal effects on the safety of the winch (extraordinary tests, e.g. after a

long period of inactivity, accidents, natural events).

– After repair works that could have an influence on the safety of the

winch.

Technical experts (AP2) are persons, who have sufficient knowledge

based on their specialist training and experience, in the areas of

winches, lift and pull systems and the relevant official occupational

health and safety rules, accident prevention regulations, guidelines and

generally accepted engineering rules (e.g. EN standards), to evaluate

the operational safety of winches, and lift and pull systems. Technical

experts (AP2) are to be nominated by the operator of the equipment.

Performance of the annual occupational safety inspection as well as the

training required to obtain the aforementioned knowledge and skills can

be provided by haacon hebetechnik.

9. MAINTENANCE RECOMMENDATION

The operator determines the intervals themselves based on frequency

of use and the operating conditions.

– Regular cleaning, no steam jets!

– Carry out visual check on inaccessible brakes / locks every 5 years at

the latest, replace brake pads as required.

– General overhaul by the manufacturer after 10 years at the latest.

CAUTION!

Only perform inspection, maintenance and repair work on an

unloaded hoist. Only allow work on brakes and locks to be per-

formed by qualified specialist personnel.

Maintenance and inspection work

Intervals

Visual check of the rope hooks (load carrier)

Before

every use

Function of the winch

Condition of the rope and lifting equipment

Brake function under load

Grease bearing of drive pinion

Quarterly

Annually

Check rope for wear acc. to DIN ISO 4309 and service

Check fastening bolts for secure seating

Check all parts of the winch and crank for wear, if ap-

plicable, replace defective parts and lubricate.

Annually

Check type plate for legibility

Have an inspection performed by an expert

Lubricant recommendations:

Multi-purpose grease per DIN 51502 K3K-20

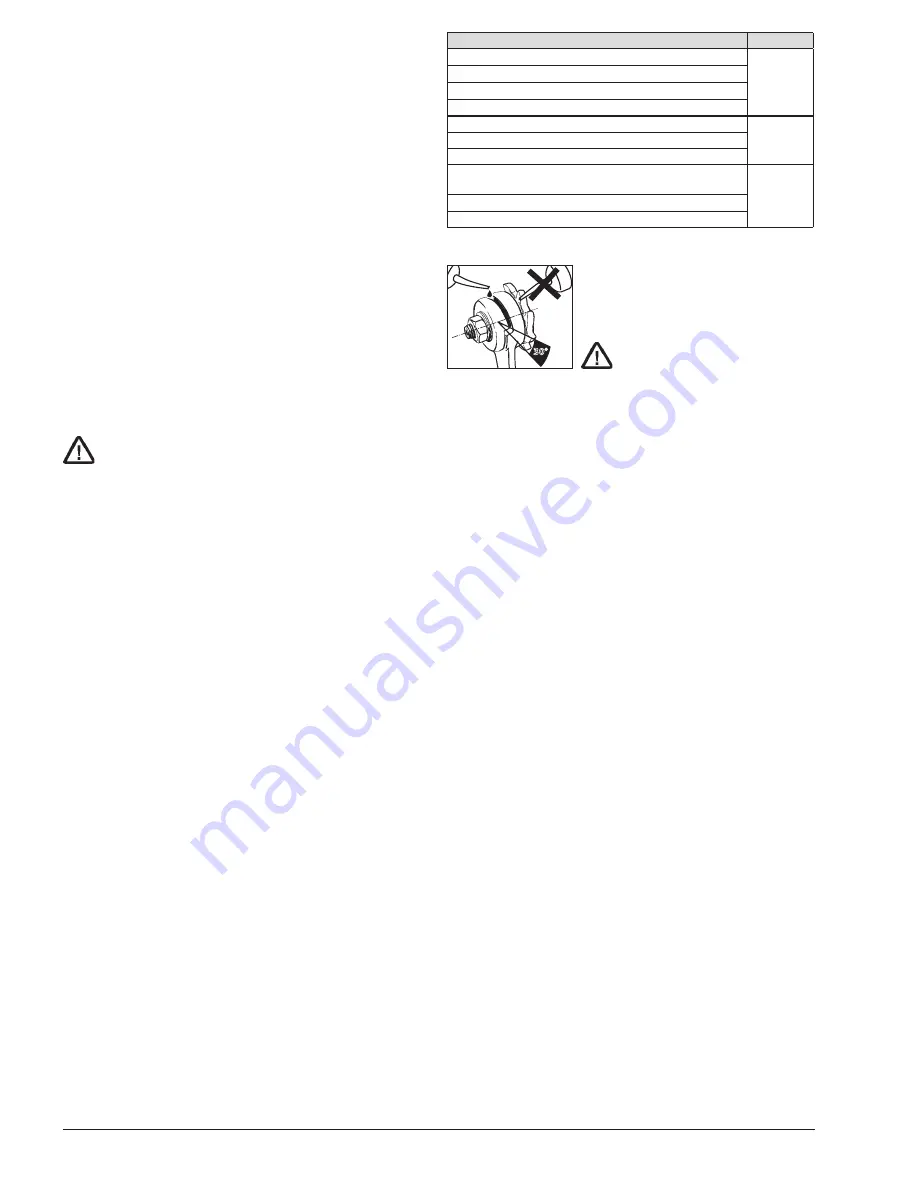

Safety crank

1- 3

30°

max

If sluggishness occurs during lowering, pour

a few drops of oil into the gap in the crank

cam.

Safety cranks with a gap aperture >30°

should be replaced. Repair must be carried

out by only by the manufacturer.

CAUTION!

Only disassemble the crank, ratchet

brace and locking pawl when the

equipment is not under load!

Do not oil or grease the brake pads!

10. SPARE PARTS

When ordering spare parts it is essential to quote:

– The type and serial number of the equipment / item and part number

11. DISASSEMBLY, DISPOSAL

– Make sure to observe the safety instructions.

– Dispose of the equipment and the substances within it in an environ-

mentally responsible manner.

Louis Reyners BV

|

Symon Spiersweg 13a, 1506 RZ Zaandam

|

+

31 (0) 75 650 47 50

|

|

www.LR.nl