094025_o_de_gb_fr_dk_wkstwin_s

haacon hebetechnik gmbh T49 (0) 9375 - 84-0 Fax +49 (0) 9375 - 84-66

6. OpERATiOn

Loads can be raised and lowered

only in low gear.

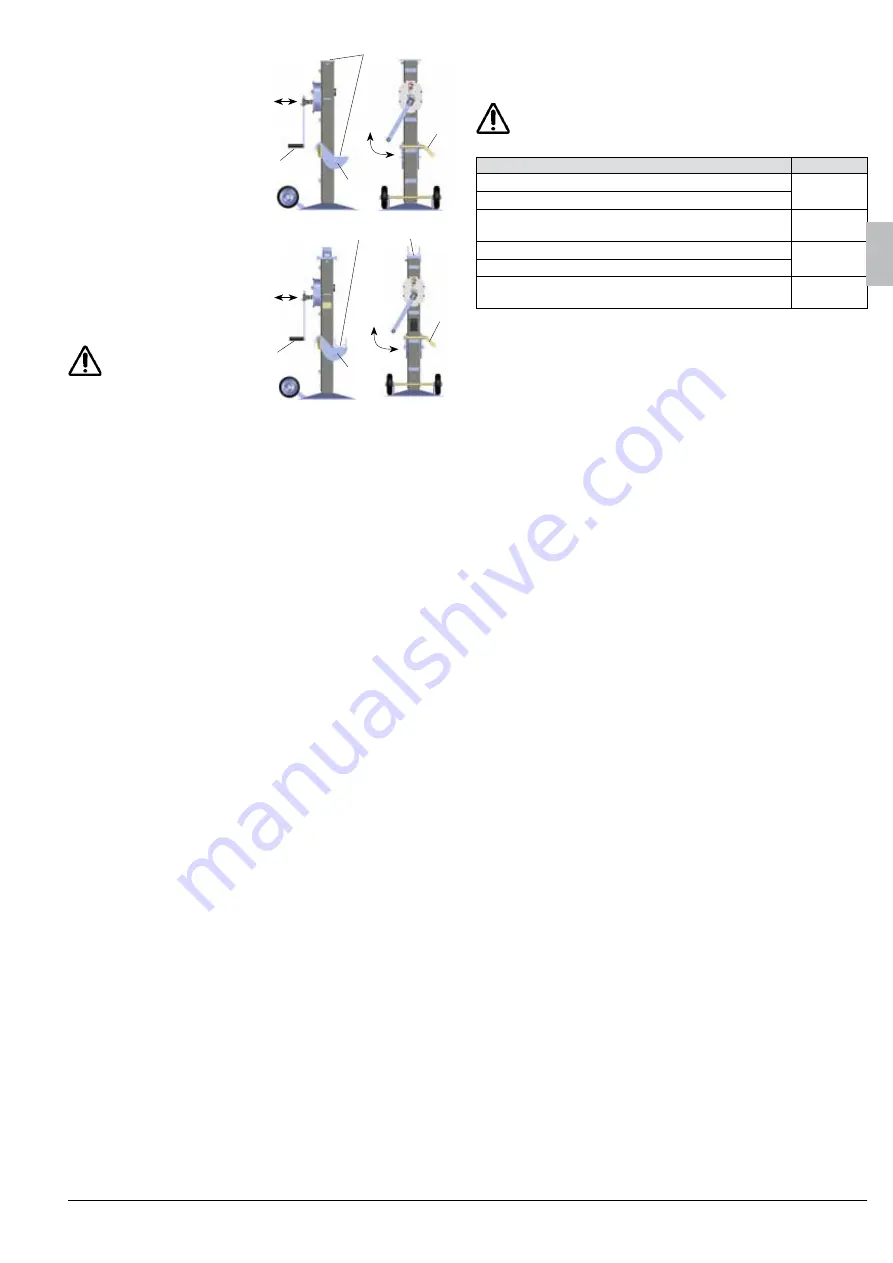

Raised / lowered:

Turn the hand crank clockwise

when lifting.

Turn the hand crank anticlockwise

when lowering.

Switching to rapid traverse gear:

Pull the crank out until it reaches the

stop.

Switching to load gear:

Push the crank in,

the switch lock must engage.

Adjusting the lifting claw:

The hoist claw can be positioned in

four fixed positions on the shaft.

Pull the clip connector out, remove

the socket pin and adjust the lifting

claw to the required height. After

attaching the lifting claw, secure the

socket pin with a clip connector.

Support loads safely!

The load capacity of the

ground must be at least

25 kN/cm².

Observe the load specifications on the vehicle’s axles.

Attach the load as close to the load attachment surfaces as

possible.

Secure the height-adjustable lifting claw with a spring clip after attaching.

After lifting a little, check that the load has been picked up safely.

During lifting and lowering movements observe the load and lifting

equipment at all times. Do not leave raised loads unattended.

Remove the crank after reaching the required working position in order

to prevent the unit being actuated inadvertently.

The crank force increases significantly when the unit’s maximum posi-

tions are reached. Stop lifting.

Do not use the unit outdoors if the wind is gusty. Set down loads that

have already been lifted or secure them accordingly.

7. ChAnGinG ThE SET-up lOCATiOn

The unit is equipped with wheels due to its weight.

The unit is mobile according to the barrow principle.

8. TESTinG

The equipment must be inspected in accordance with the conditions of

use and the operating conditions at least once per year by an authorised

person for testing per TRBS 1203 (Technical expert) (testing per BetrSi-

chV, §10, sect.2 represents implementation of EC Directives 89/391/

EEC and 2009/104/EC and the annual occupational safety inspection per

DGUV-V 54, §23, sect. 2 and DGUV-G 309-007).

These inspections must be documented:

– Before commissioning.

– After significant alterations before recommissioning.

– At least once per year.

– In the event of unusual occurrences arising that could have detrimen-

tal effects on the safety of the winch (extraordinary tests, e.g. after a

long period of inactivity, accidents, natural events).

– After repair works that could have an influence on the safety of the

winch.

Technical experts are persons, who have sufficient knowledge based

on their specialist training and experience, in the areas of winches, lift

and pull systems, and familiarity with the relevant official occupational

health and safety rules, accident prevention regulations, guidelines and

generally accepted engineering rules (e.g. EN standards), to evaluate

the operational safety of winches, and lift and pull systems. Authorised

persons for testing are selected and commissioned by the operator of

the unit.

carnk

up

down

socket

pin

load bearing surfaces

Type 1094

crank

up

down

socket

pin

load bearing surfaces

Type 1095

lifting claw

lifting claw

9. MAinTEnAnCE RECOMMEnDATiOn

The operator determines the intervals themselves based on frequency

of use and the operating conditions.

– Regular cleaning, no steam jets!

– General overhaul by the manufacturer after 10 years at the latest.

CAuTiOn!

Only perform inspection, maintenance and repair work on an

unloaded hoist. Only allow work on brakes and locks to be per-

formed by qualified specialist personnel.

Maintenance and inspection work

intervals

Visual and functional tests

Before

every use

Brake function under load

Relubrication (lubricating nipple), while doing so deploy

and retract the unit over its full stroke length

Every 6

months

Check type plate for legibility

Annually

Professional inspection according to DGUV-V 54

Check gear parts, replace if necessary, lubricate

Every 2 - 5

years

lubricant recommendations:

Multi-purpose grease per DIN 51502 K3K-20

10. SpARE pARTS

The following data should be given with each order:

– Type number and serial number of the equipment / Pos. and Part

number.

11. DiSASSEMBly, DiSpOSAl

– Make sure to observe the safety instructions.

– Dispose of the equipment and the substances within it in an environ-

mentally responsible manner.

GB