Owner’s Manual

HK3819 / HK5523

Page 15

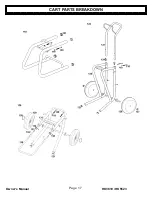

PRIME VALVE SERVICE

Part # HK-3500B ( older version )

Removal

Place 5/8” wrench on flats of bleed valve housing (Ref # 4) and remove valve assembly from the manifold (Ref #

39).

Remove the ball (Ref # 3) seat (Ref # 2) and the crush washer (Ref # 1) from the manifold. Inspect for worn or

damaged parts.

Drive the roll pin (Ref # 9) out of the valve knob (Ref # 10) and separate the knob from the stem.

Unthread the stem from the valve housing (Ref # 4).

Remove and replace stem seals, taking note of their correct sequence

Installation

Lubricate the seals and install the stem in the reverse fashion. Install the knob and pin.

Thread the valve knob through the housing counter clockwise until it bottoms out. Drop new ball into valve

housing.

Apply a liberal amount of grease to both sides of seat. Place into end of housing, with the tapered end towards

the ball. Add crush washer to the assembly. The grease will hold the parts to gather while you thread the

assembled parts into the manifold. Tighten securely.

NOTE: The grease will be flushed out during the prime cycle on the next use.

Ref #

Part #

Description

1

11A-3CP

Crush washer

2

11A-4

Prime valve seat

3

11A-5TC

Prime valve ball, tungsten carbide

4

HK-3005

Prime valve housing

5

02-22-2007

Body o-ring

6

606-8

Stem o-ring

7

606-15

Back up ring

8

HK-3010

Prime valve stem

9

HK-3020

Pin, Prime valve knob

10

HK-3015

Knob, prime valve

11

HK-3030

Label, “close”

HK-3500B PRIME VALVE

*

HK-3600BRK

Prime Valve Repair Kit, Includes Ref # 1-3, 5-7