4

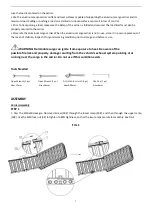

STEP 2

2. Place the bottom bracket (1#) on the bottom of the carrier frame (5#) and position the square hole. The M10*45mm

ring screw (4#) is then passed through the bottom bracket (1#) and the carrier frame (5#) and the U clamp (2#). The

M10 lock nut (3#) is finally tightened. See FIG 2.

FIG 2

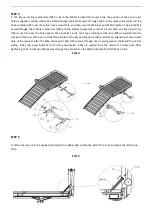

STEP 3

3. The spoon shaped fixed plate (6#) protrusion side is faced to the inside of the carrier frame (5#) and is mounted on

the left of the carrier frame (5#), aligns two round holes, so that the M10 x 20mm ring screw (8#) passes through the

spoon shaped plate (6#) and the upper round hole of the carrier frame (5#) in turn, and then uses the M10 lock nut (3#)

to tighten. The button socket cap screw M10 x 25mm (7#) from the inside of the carrier frame (5#) through the carrier

frame (5#) and the spoon shaped fixed plate (6#) from the top of the second round holes, and then the M10 lock nut

(3#) tightened. Finally, the M10 x 20mm ring screw (8#) is made from the right side of the 10 flat washer (9#) and the

upper first round hole of the carrier frame (5#) from the right side of the carrier frame (5#), and the M10 lock nut (3#) is

tightened. See FIG 3.

FIG 3

FIG: 1

Note: After complete the installation, we

must ensure that the 4 bolts are on the

same straight line. This is the correct way

of installation.

The head of the

ring screw

(4#) goes towards the

outer side of the

carrier

frame (5#).

Содержание 712140

Страница 6: ...6 STEP 6 Folding steps See FIG 6 FIG 6...