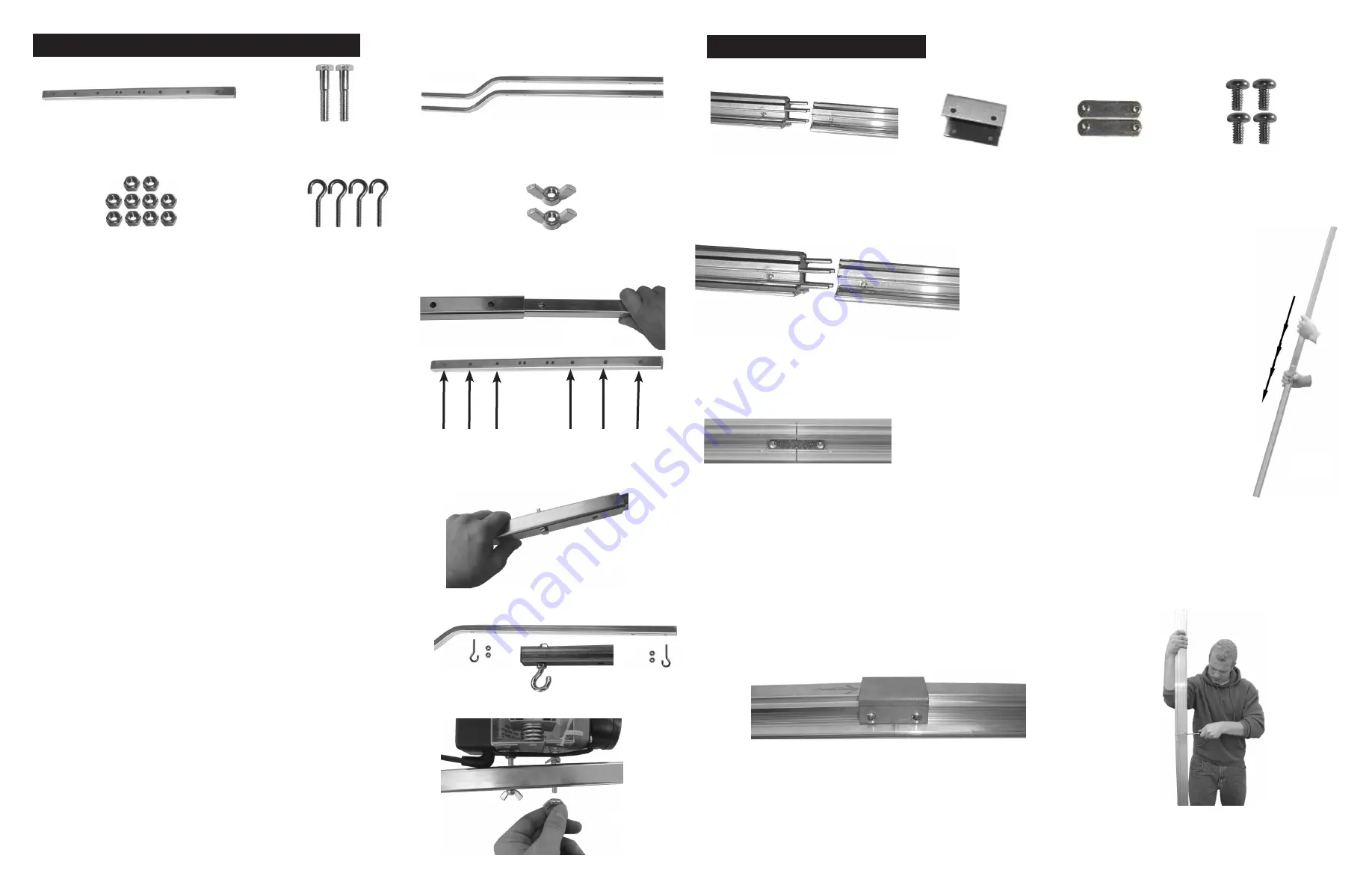

Start

by inserting the 2 crossbar ends into the cross-

bar splint.

Next

align the holes in the crossbar splint with the holes

in the crossbar. There are 3 holes in each side of the

splint to accommodate different crossbar widths. You

must use the same holes in each side so the crossbar

ends span an equal distance from the center of the

splint (Fig 4-1).

After

inserting the 2 crossbar ends into the crossbar

splint secure them using the 2 - 1/4” x 1 1/2” crossbar

to splint screws and 2 of the 1/4” hex nuts (Fig 4-2).

Next

install the 4 - lamp hanging eye screws with the

remaining 1/4” hex nuts (Fig 4-3). There are two sets

of holes on each end to accommodate different light

widths. Note: As in the LightRail 5 logo you can see

the crossbar ends are bent. If you have a particularly

high ceiling you may want to hang the crossbar with

the bends down opposite the logo. This you will need

to decide so the 1/4” eye screws are mounted facing

the right way.

Now

that the crossbar is assembled it can be mounted

to the Drive Motor. Locate the 2 holes in the center of

the crossbar splint. Slide them over the two 1/4” screws

protruding from the bottom of the Drive Motor and fas-

ten it using the 2 - 1/4” wing nuts (Fig 4-4). Be sure

to tighten the wing nuts until the 1/4” screws on the

bottom of the Drive Motor begin to protrude from the

bottom of the wing nuts (Fig 4-4).

STEP FOUR: INSTALLING THE CROSSBAR

4 - Lamp Hanging

Eye Screws

1 - Crossbar splint

2 - 1/4” Wing Nuts

2 - Crossbar ends

2- 1/4” x 1 1/2”

Crossbar to Splint Screws

10 -1/4” Hex Nuts

Tools you will need:

7/16” wrench, pliers

Fig 4-1

Crossbar Width Adjustment Holes

Fig 4-4

Fig 4-3

Fig 4-2

STEP ONE: RAIL ASSEMBLY

Start

by matching ends of Rail halves

with arrows. While making sure the

alignment pins line up with their cor-

responding holes, push the two Rail

halves together (Fig 1-1); if needed

you can tap the Rail end on the floor to

assist in pushing the Rail halves all the

way together (Fig 1-2).

Next

insert one slide nut in the slide nut channel

on each side of the Rail. Push them towards the

middle until they cover the joint where the 2 Rail

halves meet (Fig 1-3).

Last

slide the Rail coupler over the top of the Rail and start each of the 4 - #10 machine

screws into the threaded holes in the slide nuts (Fig 1-4). Tighten them just until they are

snug, then stand the Rail on its end and torque the screws tight while pushing down on the

Rail (Fig 1-5).

Tools you will need: Phillips head screwdriver

1 - Rail Coupler

2 - Slide Nuts

2 - Rail Halves

4 - #10 x 3/8”

Machine Screws

Fig 1-3

Fig 1-5

Fig 1-4

Fig 1-2