IGLOO NET

MODEL NO.

GS-W803

GSWeb Playground Equipment

8

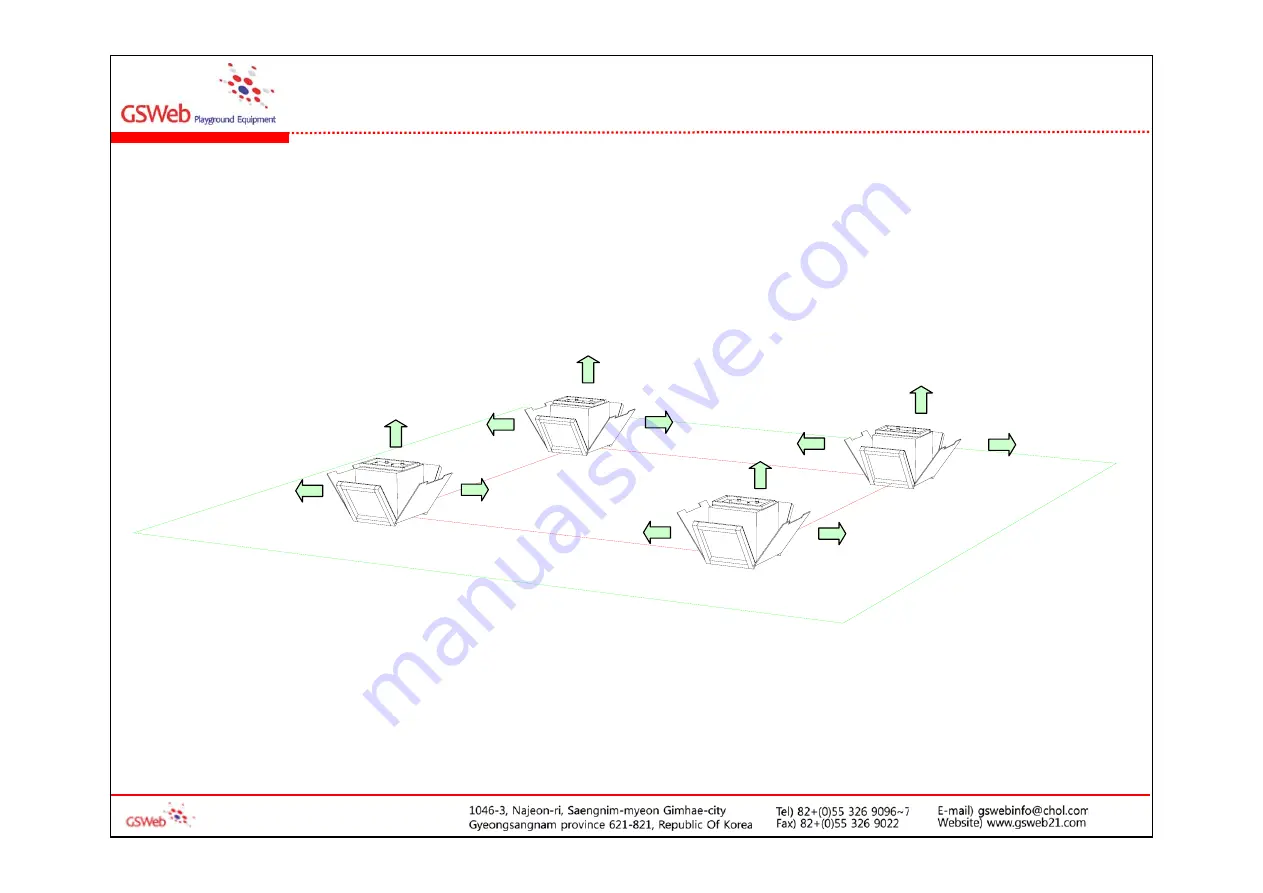

Remove Wood Support Frame

Remove wood support frame from dry concrete blocks

After concrete has cured enough, remove frame and replace soil in area

around footing to subgrade level

Figure-8 :

Remove wood support frame