2. Safety

PNEG-681CE

CE Compliant Series II Bucket Elevator

13

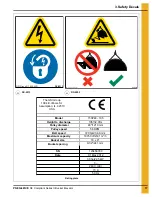

Correct Use of the Bucket Elevator (Continued)

3. Never operate with guards removed or inspection covers open.

4. Never open or work on the moving parts of the Bucket Elevator unless:

a. It has been run completely empty of grain. (A loaded elevator might result in unexpected

movement of the belt and buckets even when locked out.)

b. It is locked out and tagged out at the main electrical isolator.

c. All equipment working with the elevator are also locked out and tagged out.

5. The elevator must be installed vertical in all directions and must not be used at any other angle.

6. Do not fix a hoist or other lifting equipment to the Bucket Elevator, nor to the ladders or platforms

attached to the elevator.

7. Ladders and platforms attached to the elevator are for personnel access only and must not be used

to carry or support heavy pieces of equipment.

8. Do not exceed the maximum ladder and platform load, noted on the warning decal (225 kg).

9. Never alter or adjust the elevator from it is original specification.

10. Always lock out and tag the electrical power to the elevator before working on it.

11. Do not use the elevator in an enclosed, potentially explosive area.

Working at Heights

The equipment has been designed to operate primarily at ground level, at some stages during the life cycle

it will be necessary to work at heights. For this reason the equipment has been provided with access

ladders and platforms, to minimize the risk to health and safety. In addition attention should be paid to the

following safety requirements.

1. The ladders, platforms and walkways are for use by competent and trained personnel only. NEVER

allow children or members of the general public to gain access to the equipment, its ladders or

access platforms.

2. Where the equipment is sited in an unsecured location, access must be restricted by use of security

fencing and lockable gates.

3. Lower sections of ladders on the equipment should be fitted with a lockable safety gate, to prevent

unauthorized access.

4. The equipment should be OFF and all power LOCKED OFF before work on or in the equipment.

Ensure the power isolator is OFF and LOCKED and TAGGED to prevent inadvertent re-start.

This must include all equipment attached to the elevator on which you are working.