English (GB)

39

9. Maintenance

9.1 Maintenance of the dosing pumps

A drop in performance of the dosing pumps may be caused by

contamination in the suction and discharge valves.

9.1.1 Dismantling and cleaning the valves

1. Unscrew the suction and discharge valves.

2. Use a pin (

∅

2) to press out the ball cage, ball and O-ring from

below.

3. Replace damaged parts.

When re-assembling, observe the correct position of the parts,

see fig.

Fig. 25

Construction of the valves

9.1.2 Dismantling the diaphragm

For safety reasons, the dosing diaphragm should be replaced

after a maximum of 2000 operating hours.

1. Insert the suction lines of the pumps into a water tank, and run

the system until the dosing heads of the pumps have been

well purged with water.

2. Open venting screws by one rotation until the venting lines are

also purged. Switch off the system.

3. Loosen the four dosing head screws.

4. Remove the dosing head, and unscrew the diaphragm by

rotating to the left.

Assembly

1. Insert the intermediate ring so that the relief hole points

downwards.

2. Screw in the diaphragm.

3. Switch on the pump briefly until the diaphragm is located at

the rear dead point.

4. Carefully fit the dosing head, and uniformly and gently tighten

the screws in a diagonally opposite sequence, so that the

dosing head is not damaged.

5. Vent the pump.

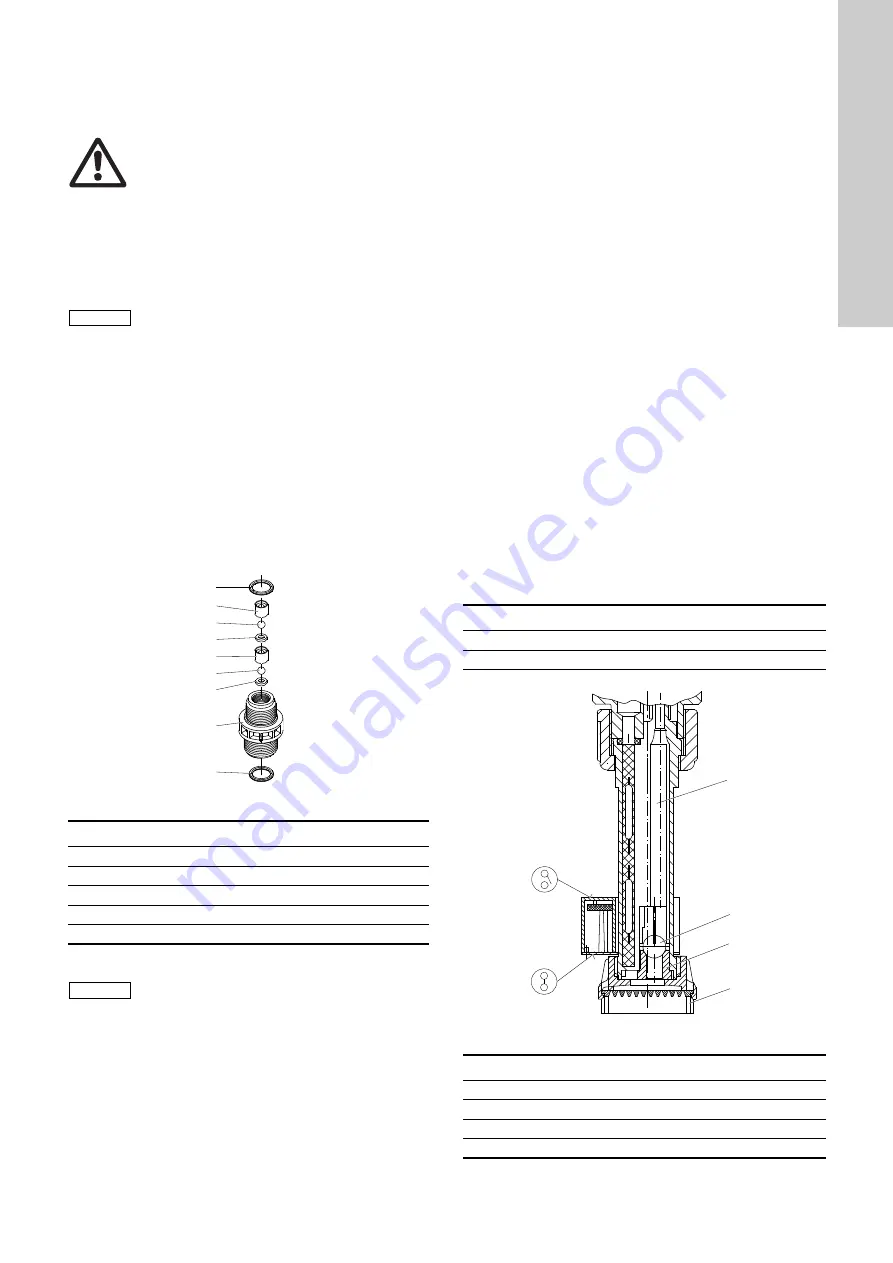

9.2 Maintenance of the suction lines

The suction lines are equipped with foot valves and filter nuts.

The Reed contacts are integrated in the suction line body.

The floats with magnet core are located axially on the valve body

and are sliding.

The foot valve should be dismantled and cleaned occasionally,

at the latest when the suction performance drops.

The function symbol (NO contact) must be present on the top

surface of the two floats.

If this is not the case, disconnect the float and reverse the

polarity.

Fig. 26

Suction line, spare parts

Warning

Before any maintenance work, i.e. when exchanging

parts and gaskets, the entire system has to be rinsed

with water.

Before maintenance work, all chemicals must be

completely removed!

When handling acids or lyes, wear appropriate

protective clothing.

Maintenance and repair work must only be carried

out by authorized specialists.

Note

According to the German accident prevention

regulations GUV 8.15 and VGB 65 § 19, chlorine

dioxide systems must be regularly checked for

safety, at least once a year and prior to every startup,

by a specialist.

This check can be carried out by the after-sales

servicing department during the six-monthly

maintenance.

TM

04

82

17

45

10

Pos.

Description

1

Valve body

2

Ball cage

3

Seat

4

Ball

5

O-ring

Note

When installing the valves, make sure that the flow

direction is correct (arrow).

The O-ring must be inserted correctly into the

provided groove.

OCD-164

Product No.

-30 to -220

95730320

(553-1995)

-350 to -2000

95730321

(553-1996)

TM

04

8

221

4

510

Pos.

Description

1

Float switch, PVC

2

Ball

3

Valve seat, grey PVC

4

Filter nut, PVC grey

Содержание Oxiperm OCD-164

Страница 2: ...2...

Страница 247: ...Fran ais FR 247 4 crou filtre PVC gris...

Страница 420: ...RU 420 1 10 1 10 1 20 TrinkwV 2001 0 4 1 10 2 1 10 3 EN 12671 D 15 7 5 DIN EN 938 9 0 DIN EN 939 HCl NaClO2...

Страница 422: ...RU 422 10 10...

Страница 430: ...RU 430 5 4 2 0 1 1 8 5 4 3 42 9 5 4 4 ClO2 ClO2 ClO2 2 3 3 TM04 8200 4510 11 1D O2 O TM04 8201 4510 1D O2 O...

Страница 431: ...RU 431 10 5 5 2 1 5 5 6 5 6 1 5 6 1 TM04 8202 4510 50 60 6 20 11 1D O2 O...

Страница 432: ...RU 432 5 6 2 1 2 3 20 20 4 11 4 5 4 4 5 4 6 5 6 5 6 TM04 8203 4510 1 20 2 3 4 5 6...

Страница 455: ...RU 455 34 HCl 35 HCl 36 NaClO2 37 NaClO2 38 H2O 39 H2O 40 ClO2 41 HCl 42 NaClO2 43 H2O 44 45 46 47...

Страница 526: ...526...