English (GB)

15

8.4.3 Checking the outlet pressure and flow rate

Declining performance can indicate the need for an

overhaul. Regardless of performance, the pressure

and flow rate must be stable, and rapidly changing

pressure or flow rate indicate system problems on

the inlet or outlet side.

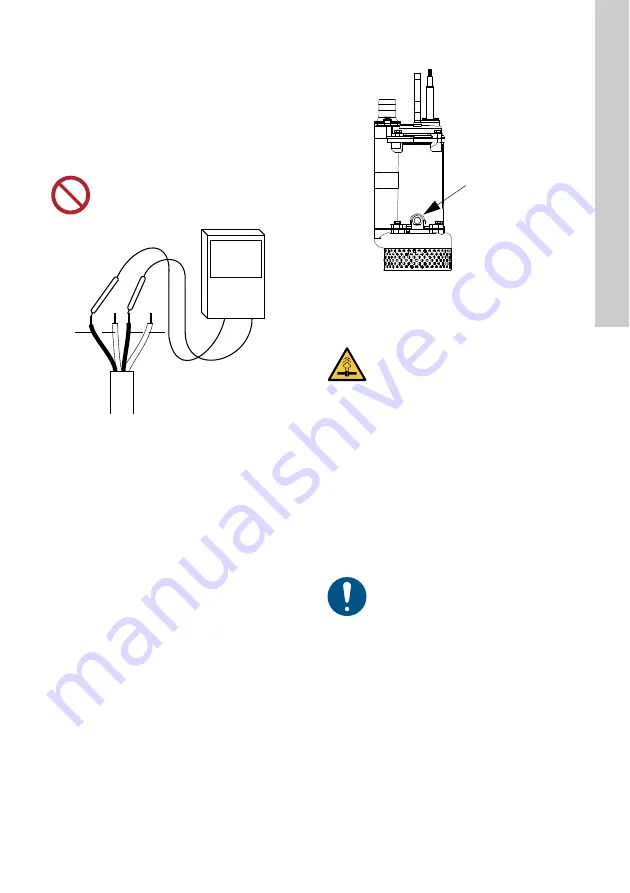

8.4.4 Inspecting the seal sensor

Check the resistance of the seal sensor with a

multimeter as shown in fig.

Fig. 15

Resistance check

8.4.5 Oil check and oil change

Fig. 16

Position of oil plug

1. Loosen the oil plug. See fig.

2. Remove the oil plug and check the oil level.

3. Take a sample to inspect the condition of the oil.

4. If the oil needs to be changed, place a clean

container under the pump to collect all the

drained-off oil.

5. Tilt the pump with the oil-filling hole pointing

downwards in order to drain the pump of oil.

If the drained oil is contaminated or opaque, this

is an indication of an impending mechanical shaft

seal failure. Replace the mechanical seal.

6. Fill fresh oil into the oil chamber through the oil

filling hole. Use lubrication oil ISO VG 32 Mobil

DTE 24 turbine oil 90 or equivalent.

8.4.6 Inspection and adjustment of impeller

clearance

Check the clearance between the impeller and the

wear plate. Recommended clearance is 0.3 - 0.5

mm. Replace or repair as necessary.

Do not use a megger as it will damage the

control circuit of the seal sensor.

TM

04

41

19

08

0

9

20 K

Ω

TP

TP

SS

SS

TM

04

41

44

090

9

CAUTION

Pressurised system

Minor or moderate personal injury

- When loosening the oil plug of the oil

chamber, note that pressure may have

built up in the chamber. Do not remove

the oil plug until the pressure has been

fully relieved.

Used oil must be disposed of in

accordance with local regulations.

Oil plug