14 OM-TDB/6

Maintenance

NOTICE: Contact an authorized representative when repairs are required.

A Maintenance & Service Log is provided at the back of this manual. Each time

maintenance is performed on your kettle, enter the date on which the work was done,

what was done, and who did it. Keep this manual on file and available for operators to

use. Periodic inspection will minimize equipment down time and increase the efficiency

of operation. The following points should be checked:

1.

Jacket Vacuum/Removing Air from Jacket (by Operator)

Every day, while the kettle is cold, read the pressure/ vacuum gauge. A

positive reading or a negative reading between zero and 20” vacuum on the

pressure/ vacuum gauge indicates excess air in the jacket. Air in the jacket

slows kettle heating and can prevent the kettle from reaching operating

temperature. To remove air:

To remove air:

a.

Start the unit. (See “Operation” section).

b.

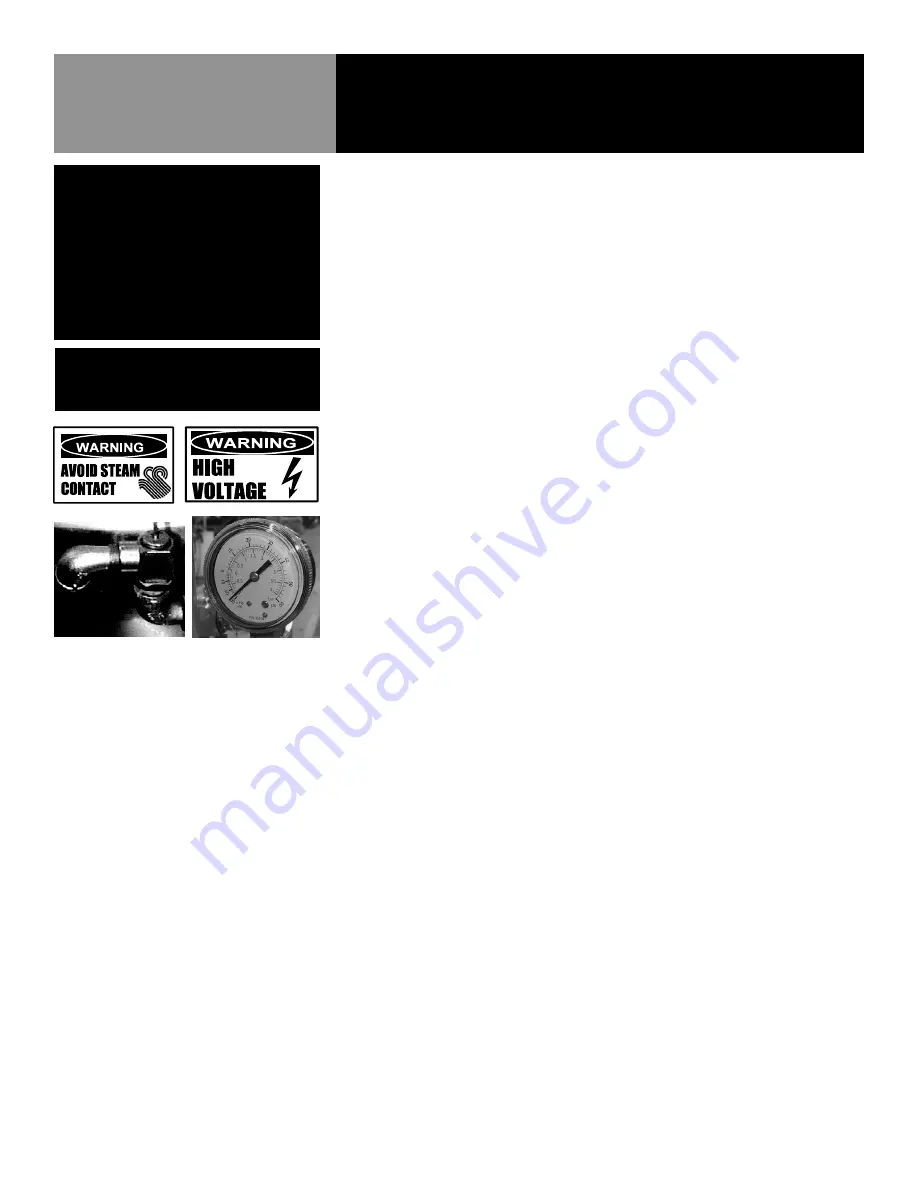

Make sure the elbow on the outlet of the pressure relief valve is turned

so that escaping steam is directed down toward the floor. Be sure and

follow the instructions on the attached pressure relief valve tag.

c.

When the pressure/vacuum gauge reaches a positive pressure reading

of 5 PSI (0.35 Bar/ 34.5 kPa), release trapped air by lifting the pressure

relief valve ring for about one second. Repeat this step, then let the

valve ring snap closed, so the valve will seat properly and not leak.

2.

Pressure Relief Valve (by Operator)

At least twice a month, test the pressure relief valve. Test the valve with the

kettle operating at 15 PSI (1.1 Bar/105 kPa), by holding the test ring for at least

five seconds. Then release the ring and permit the valve to snap shut. If the ring

does not activate, if there is no discharge, or if the valve leaks, stop using the

kettle immediately and contact a authorized service representative.

3.

Grease / Lubrication (by Service)

At least twice a year, grease the two trunnion bearings. The bearings are

located within the kettle support housing. Remove the access panels from the

support housing with a screwdriver to gain access to the grease fittings. Use

a lithium-based, multi-purpose grease. When the access panels are removed,

the mounting bolts for the trunnion bearings and tilt switch can also be

checked for tightness. When finished, reassemble access panels to support

housing.

4.

Jacket Filling

Every day, before you turn on the unit, make sure the water level is

approximately in the center of the water gauge glass. The jacket was filled at

the factory with the proper amount of treated water, and is airtight, but over

time steam may be vented and water lost.

From time to time, you may need to restore the water to its proper level. The

procedure for adding water follows.

WARNING

AVOID ANY EXPOSURE TO THE STEAM

BLOWING OUT OF THE PRESSURE

RELIEF VALVE. SEVERE BURNS CAN

RESULT ON EXPOSED SKIN.

FAILURE TO CHECK PRESSURE RELIEF

VALVE OPERATION PERIODICALLY

COULD RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO EQUIPMENT.

Make sure that the

open end of the elbow

on the pressure

relief valve is directed

downward.

The pressure gauge

should show a

vacuum of 20 to 30

inches when the

kettle is cold.

CAUTION

KEEP GREASE AWAY FROM ELECTRICAL

PARTS LOCATED NEAR THE GEARS.