9

OM-BPM-15/30/40G(C,A) (CE) INTERNATIONAL

Pilot will not light.

User

a. Lighting procedure, to ensure that the instructions in the

Operation section of this manual are followed.

Authorized

Service Rep

Only

b. That the pilot gas supply line is purged of air. X

c. Pilot gas adjustment screw, to ensure that it is open. X

d. Pilot tubing and orifice for clogging. X

Pilot flame goes

out when

Combination

Control knob is

released.

Authorized

Service Rep

Only

a. Pilot gas adjustment. X

b. Are connections from Powerpile generator to Pilotstat

power unit and Powerpile operator clean and secure? X

c. Are open and closed circuit output voltages of the

generator in the acceptable range shown by the charts

in the manual for the W720 Systems Tester? X

d. Resistance of the Pilotstat power unit. X

e. If an appropriate meter is not available, replace the

generator first, then the power unit. X

Pan will not heat,

and pilot light

is out.

User

a. Is the Combination Gas Control Valve knob turned ON?

b. Check the pilot tubing and orifice for clogging.

Authorized

Service Rep

Only

c. Are connections from Powerpile generator to Pilotstat

power unit and Powerpile operator clean and secure?X

d. Are Open and closed circuit output voltages of the

generator in the acceptable range shown by the charts

in the manual for the W720 Systems Tester?X

e. If an appropriate meter is not available, replace the

generator. X

Pan will not heat,

but pilot

light is burning.

Authorized

Service Rep

Only

a. That secondary thermostat switch is closed.

SERVICING & CONVERSION

IMPORTANT: BEFORE ATTEMPTING ANY SERVICING, ENSURE THAT THE GAS ISOLATING

COCK IS TURNED OFF AND CANNOT BE INADVERTENTLY TURNED ON.

ENSURE ALSO THAT THE ELECTRICITY SUPPLY IS DISCONNECTED. AFTER

ANY SERVICING OR EXCHANGE OF GAS CARRYING COMPONENTS — ALWAYS

CHECK FOR GAS SOUNDNESS!

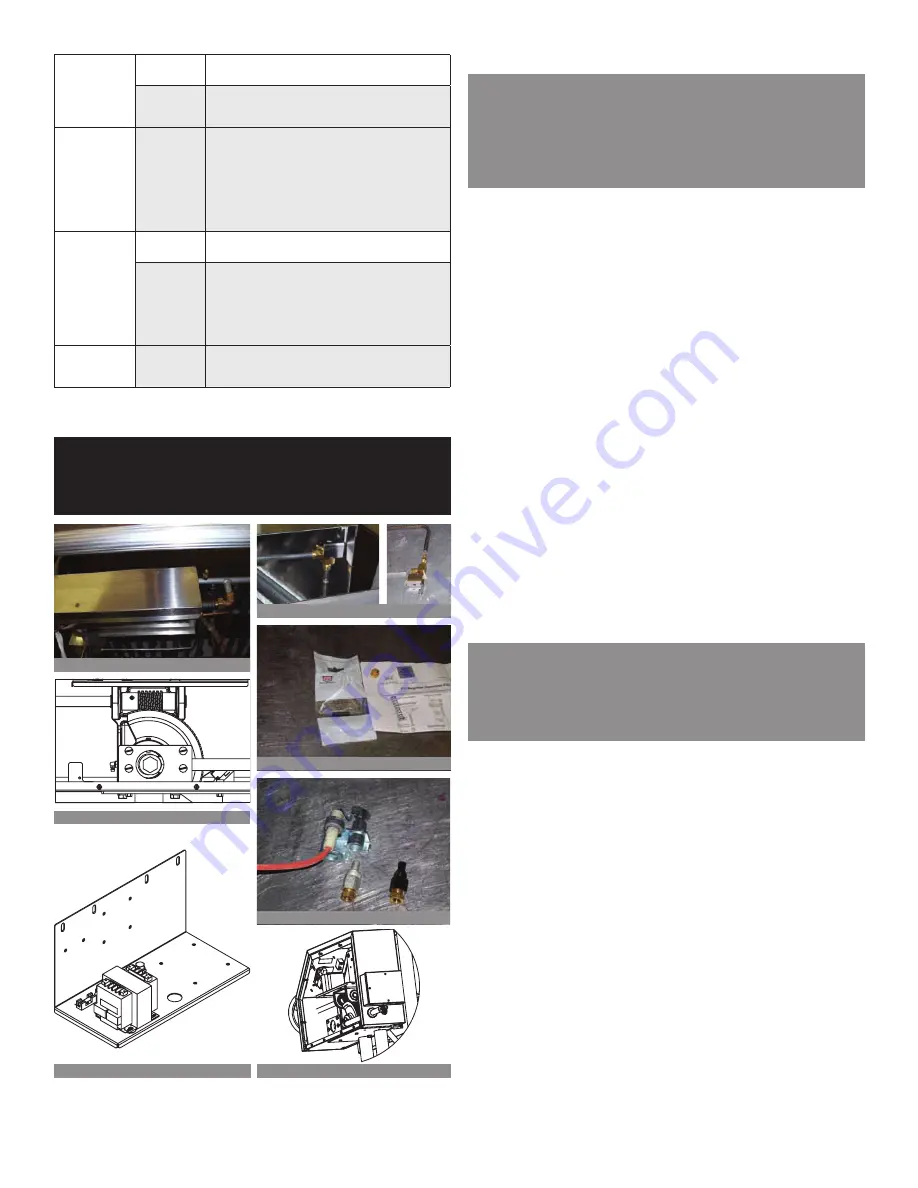

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 7

FIGURE 6

FIGURE 5

FIGURE 4

SERVICING

NOTES:

1. WHEN REPLACING WIRING CONNECTIONS REFER TO THE WIRING DIAGRAM

IN THE UNIT OR THIS MANUAL.

2. WHEN ANY THREADED GAS CONNECTION IS DISTURBED FOR ANY

REASON, THE THREADS MUST BE RESEALED WITH APPROPRIATE GAS LEAK

PREVENTION SEALANT THAT IS SUITABLE FOR THE TYPE OF GAS. UNIFIED

BRANDS/ GROEN RECOMMENDS GAS SEALANT COMPOUND SUCH AS

LOCKTITE® 243 OR UNIFIED BRANDS PART NUMBER 122002.

After Servicing

1. Test for gas soundness as specified in IGE/UP1.

2. If leaks are found, disconnect the mating parts, clean the threads and apply

recommended sealant as specified above in Note #2. as appropriate after

any gas connection has been disturbed.

3. Check for correct operation as appropriate (see Installation, CE Models, Gas

System Performance).

Regular Servicing Procedures

The following must be checked at regular intervals:

1. Burners Clean the burners periodically to maintain maximum performance.

Burners are best cleaned with a stiff bristle brush, or if necessary with a wire

brush. Take care not to damage the burner.

Clean the injector orifice with a wooden splinter or toothpick. Avoid metal

reamers, which may distort or increase the orifice size. WARNING - Do not

leave any wood splinter or bristles from brush in the burner or injector. Fire

could result.

2. Gears and Bearings: The gear housing has been fitted for proper lubrication

of moving parts. Since the gears do not run in oil, periodic lubrication with

grease is essential. Frequency of lubrication depends on operating conditions,

but should occur at least once every six months. Groen recommends the use

of a Number Two grade LGI lithium grease. Add grease through the Zerk

fittings on the gear housing until grease flows out of the bearings around the

trunnion shaft. Place a liberal amount of grease on the gear to cover the arc

that is in contact with the worm gear.

CONVERSION

NOTES:

1. SEE INSTALLATION, CE MODELS, GAS SYSTEM PERFORMANCE FOR

IMPORTANT INFORMATION. VERIFY THE TYPE OF GAS TO BE USED. IN THE

COUNTRIES LISTED IN THAT SECTION, ALL CONVERSIONS MUST BE FOR

APPROVED GAS.

2. ALL THREADED GAS CONNECTIONS MUST BE SEALED AS SPECIFIED IN

NOTE #2 IN SERVICING SECTION.

To change the type of gas used (e.g G20 to G31 natural to propane or inverse)

following parts should be changed:

1. Burner injectors. See instruction in REMOVAL OF BURNER ORIFICES at the

end of this section.

2. Igniter tube injector. This is inserted inside the igniter tube as shown in the

figures.

3. Gas valve spring. Install per instructions supplied with the spring package as

shown in figure 5.

4. Pilot orifice. Insert the black shaded orifice for G31 or propane gas as shown

in figure 6. The light colored orifice is for G20 on natural gas.

5. Data plate with correct rate and gas manifold pressure information.

After Conversion

1. Test for gas soundness as specified in IGE/UP1as appropriate after any gas

connection has been disturbed.

2. If leaks are found, disconnect the mating parts, clean the threads and apply

recommended sealant as specified in SERVICING, Note #2, at the beginning

of this section.

REMOVAL OF CONTROL CABINET PANELS

1. Remove 10 screws on cover.

2. Remove 4 screws at center of cover.

3. Lift off the removable side panel.