Model T32336 (Mfd. Since 05/22)

-29-

Operation (Cont.)

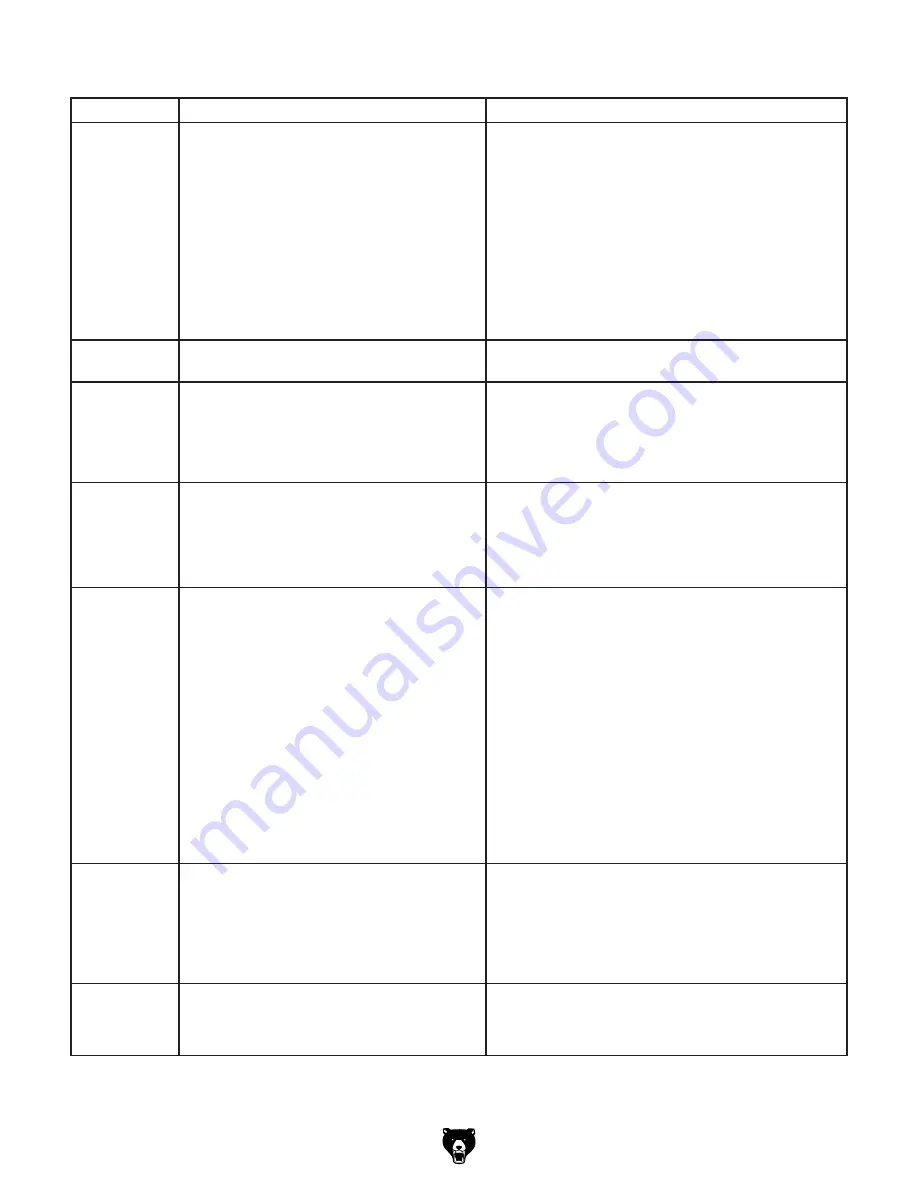

Symptom

Possible Cause

Possible Solution

Compressor

does not build

air pressure, or

does not reach

full pressure.

1. Drain valve is open.

2. Tanks need to be drained.

3. Air filter dirty/clogged.

4. Air leak in tanks or delivery pipes.

5. Check valve components are dirty/damaged.

6. Reed valve(s) not sealing.

7. Head gasket or valve body gasket leaking.

8. Worn pump piston rings.

9. Broken crankshaft or connecting rod.

1. Close drain valve.

2. Open drain valve to drain condensation, then close.

3. Replace air filter (

Page 24).

4. Check air tanks, pipes, and all connections for leaks

(

Page 26). Do not attempt to repair leaking/damaged

tank, only replace.

5. Clean/replace check valve components (

Page 30).

6. Remove cylinder head and replace reed valve(s).

7. Remove cylinder head and replace gasket(s).

8. Inspect and replace pump piston rings.

9. Replace or rebuild compressor pump.

Air leaks from

air filter.

1. Check valve components are dirty/damaged.

2. Reed valve(s) not sealing.

1. Clean/replace check valve components (

Page 30).

2. Remove cylinder head and replace reed valve(s).

Air tools have

oily discharge.

1. Tanks need to be drained.

2. In-line oiler is out of adjustment (if used).

3. In-line filter is damaged or missing (if used).

4. Compressor pump is at fault.

1. Open drain valve to drain condensation.

2. Adjust in-line oiler drip ratio or use correct viscosity oil.

3. Replace filter or in-line filter assembly.

4. Worn compressor piston, rings, or valves. Rebuild or

replace pump.

Air tools

have watery

discharge or

get cold and

freeze up with

ice during use.

1. Tanks need to be drained.

2. In-line water separator is full (if used).

3. Ambient environment has too much humidity.

1. Open drain valve to drain condensation.

2. Drain water separator.

3. Install in-line air dryer and water separator.

Air tool has low

supply pressure

but compressor

has sufficient

air pressure.

1. Air hose is too long.

2. Regulator needs to be adjusted for higher

airflow delivery.

3. Machine is undersized.

4. In-line filter is damaged or clogged (if used).

5. In-line water separator is full (if used).

6. Pressure switch cut-in/cut-out settings have

been adjusted incorrectly.

7. Air leaks in hose.

8. Regulator at fault.

9. Pressure gauge(s) at fault.

1. Use shorter hose.

2. Turn regulator knob clockwise to increase line PSI. DO

NOT exceed pressure rating of attached tool.

3. Use a smaller attachment tool or a larger air

compressor.

4. Replace filter or in-line filter assembly.

5. Drain water separator.

6. Adjust settings (

Page 31). Do not exceed cut-in/cut-

out pressures listed on data sheet (

Page 6) or inside

pressure switch.

7. Check air hoses and all connections for

leaks (

Page 26).

8. Inspect regulator for leaks. Replace if at fault.

9. Replace pressure gauge(s).

Safety relief

valve leaks.

1. Pressure switch cut-in/cut-out settings have

been adjusted incorrectly.

2. Safety relief valve at fault.

3. Pressure switch at fault.

1. Adjust settings (

Page 31). Do not exceed cut-in/cut-

out pressures listed on data sheet (

Page 6) or inside

pressure switch.

2. Test/replace.

3. Turn compressor

OFF, disconnect from power, and

empty tanks. DO NOT USE until switch is replaced.

Delivered air

is dirty or has

excessive

moisture.

1. Tanks need to be drained.

2. Delivery pipes are dirty (if used).

1. Open drain valve to drain condensation.

2. Remove delivery pipes, clean out and replace.

Содержание T32336

Страница 40: ......