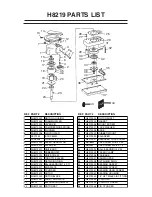

Model H8219 Air Orbital Sander

-4

-

OPERATIONS

Read the manual before operation.

Become familiar with this tool, its

safety instructions, and its operation

before beginning any work. Serious

personal injury may result if safety

or operational information is not

understood or followed.

Like all tools there is potential danger

when operating this tool. Accidents

are frequently caused by lack of

familiarity or failure to pay attention.

If normal safety precautions are

overlooked or ignored, serious

personal injury may occur.

Attaching Sandpaper

1.

DISCONNECT THE SANDER FROM

THE AIR SUPPLY!

2.

Install the

1

⁄

4

" NPT male quick-connect

fitting into the air inlet.

3.

The sanding pad for the Model H8219

measures 6

1

/

2

" X 3

1

/

2

".

New sandpaper

sheets can be obtained by cutting down

a single sheet or a piece from a roll.

Cut at least 2

1

/

2

" extra for the length to

fasten it properly.

Note:

Using sandpaper that is torn or

is smaller than the sanding pad will

cause excessive wear and damage

your sander.

4.

Attach the sandpaper by clamping it

onto both ends of the sander with the

paper clamps as, shown in

Figure 2

.

5.

Firmly press the paper clamps until the

holding spikes (

Figure 2

) push through

the sandpaper.

Figure 2.

Attaching the sandpaper.

Paper Clamp

Holding Spikes

Содержание H8219

Страница 2: ......