Introduction

Your Grizzly sandblasting gun kit features four

specialized sandblasting pattern nozzles, a col-

lection bag, and a polished aluminum media can.

Using the included pattern nozzles, your sand-

blasting gun will remove rust, scale, varnish, and

paint from the flat surface, inside and outside cor-

ners, and spot locations of your workpiece.

MODEL H8118

SANDBLASTING

GUN KIT

INSTRUCTION SHEET

Eye, lung, or hand injury could result from

sandblasting if you don't wear proper pro-

tective gear. Always wear safety goggles, a

respirator, and gloves when sandblasting.

COPYRIGHT © DECEMBER, 2006 BY GRIZZLY INDUSTRIAL, INC.

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#CR8845 PRINTED IN CHINA

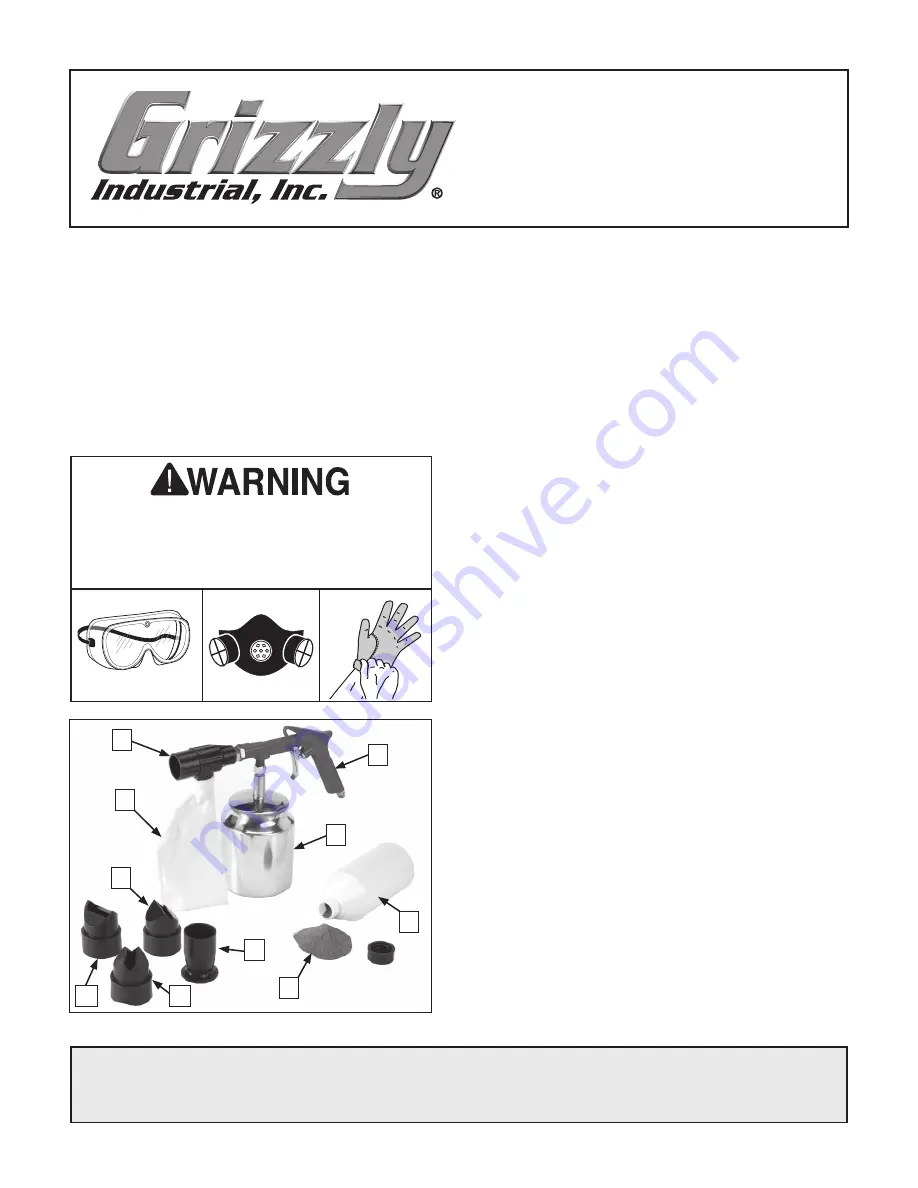

Parts & Inventory:

(Figure 1)

A.

Blast Barrel and Air Jet (P8118001) ............ 1

B.

Blast Gun (P8118002) .................................. 1

C.

Collection Bag (P8118003) .......................... 1

D.

Media Can (P8118004) ................................ 1

E.

Media Storage Bottle (P8118005) ................ 1

F.

Flat Pattern Nozzle (P8118006) ................... 1

G.

Spot Pattern Nozzle (P8118007) ................. 1

H.

Inside Corner Pattern Nozzle (P8118008) ... 1

I.

Outside Corner Pattern Nozzle (P8118009) 1

J.

Blast Media (See Below) .............................. 1

G

F

H

I

J

A

B

D

E

C

Figure 1.

Model H8118.

Air Supply Requirements

Sandblasting operations are extremely demand-

ing on small compressors and can cause a com-

pressor overload or overheated condition. Refer to

your compressor Owner's Manual and make sure

that it can handle the load of sandblasting.

We recommend using a compressor that is can

sustain at least 11 CFM at 100 PSI.

To maintain a consistent blast pattern and finish,

we recommend installing an air regulator with a

gauge in the blast gun air supply.

Keep your compressor completely isolated from

your sandblasting environment, or keep the work

area downwind from the compressor. Airborne

abrasive dust will destroy compressor rings, pis-

tons, valves, and bearings.

Make sure to increase the maintenance interval

of your compressor if using it for sandblasting

operations.

If you need help with your sandblasting kit, call

our Tech Support at: (570) 546-9663.