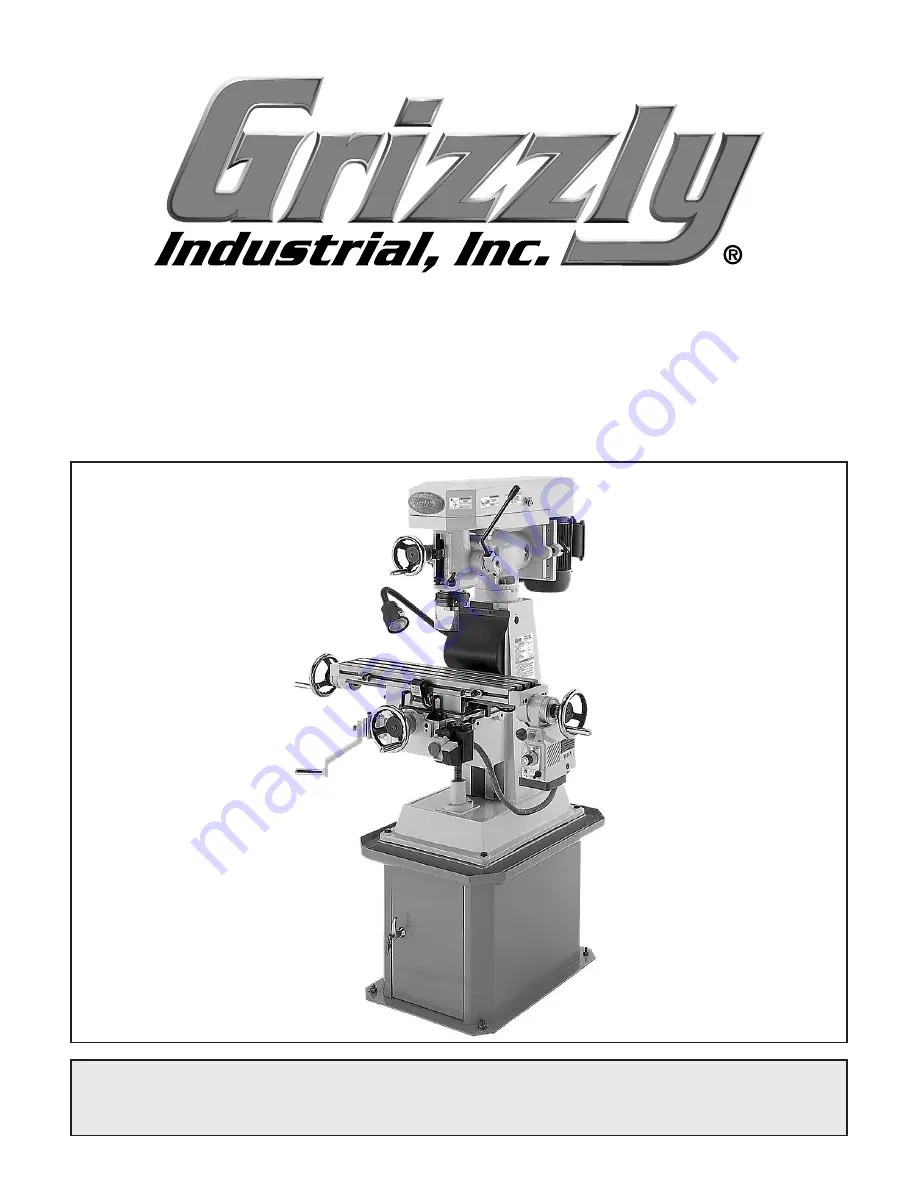

MODEL G3102/G3103

VERTICAL MILL

OWNER'S MANUAL

COPYRIGHT © OCTOBER, 2008 BY GRIZZLY INDUSTRIAL, INC., REVISED MARCH, 2015 (ST)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE

OR FORM WITHOUT THE WRITTEN APPROVAL OF GRIZZLY INDUSTRIAL, INC.

#TS11100 PRINTED IN CHINA