-30-

Model G0846 (Mfd. Since 02/18)

Review the troubleshooting procedures in this section if a problem develops with your machine. If you need

replacement parts or additional help with a procedure, call our Technical Support.

Note: Please gather the

serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

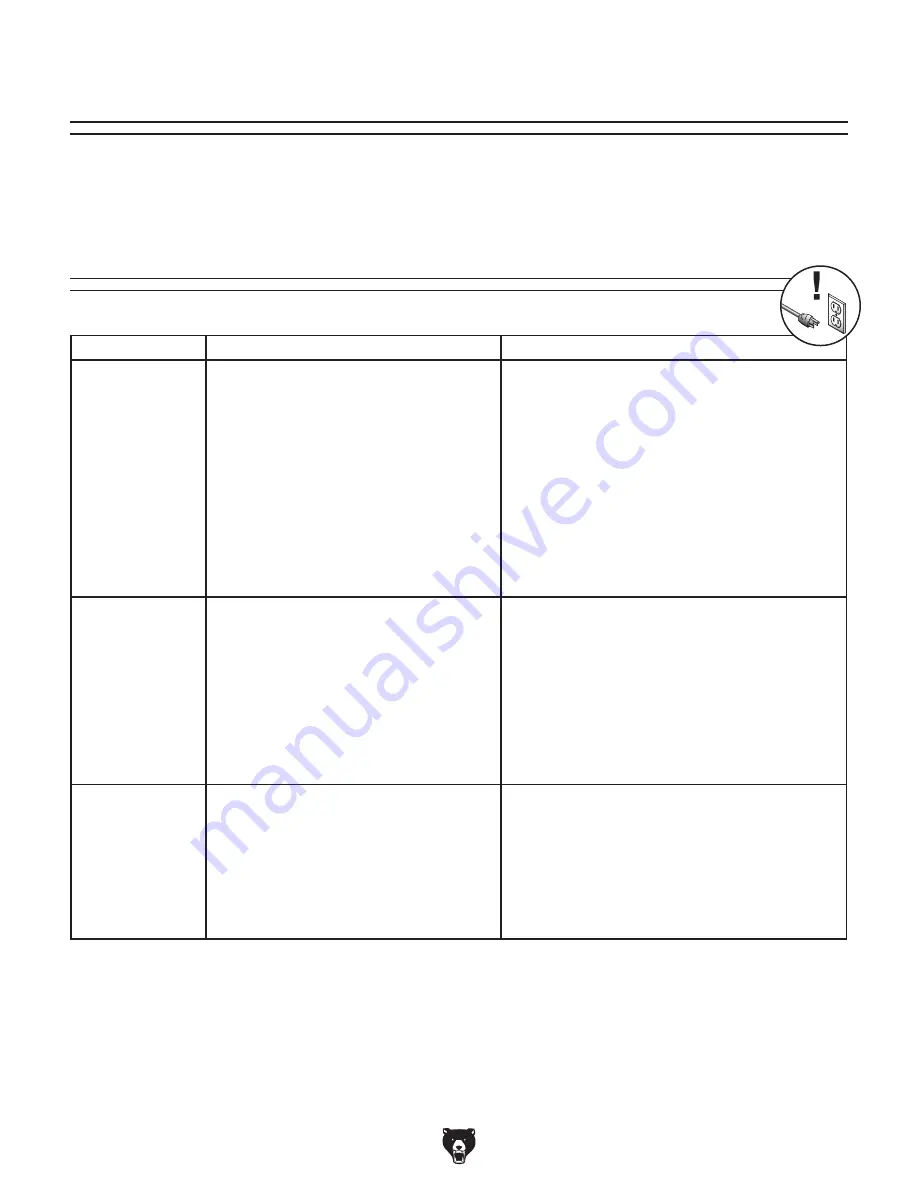

Motor & Electrical

Symptom

Possible Cause

Possible Solution

Machine does not

start or a breaker

trips.

1. Incorrect power supply voltage or circuit

size.

2. Power supply circuit breaker tripped or fuse

blown.

3. Motor wires connected incorrectly.

4. Spindle rotation switch miswired or at fault.

5. Switch disabling key removed.

6. Start capacitor is at fault.

7. Wiring is open/has high resistance.

8. Power ON/OFF switch is at fault.

9. Centrifugal switch is at fault.

10. Spindle rotation switch at fault.

11. Motor is at fault.

1. Ensure correct power supply voltage and circuit

size.

2. Ensure circuit is sized correctly and free of shorts.

Reset circuit breaker or replace fuse.

3. Correct motor wiring connections (

Page 39).

4. Rewire or replace switch.

5. Install switch disabling key (

Page 19).

6. Test/replace if faulty.

7. Check for broken wires or disconnected/corroded

connections, and repair/replace as necessary.

8. Replace faulty ON/OFF switch.

9. Adjust/replace the centrifugal switch if available.

10. Test/replace switch.

11. Test/repair/replace.

Machine has

vibration or noisy

operation.

1. Motor mount loose.

2. Motor or component is loose.

3. Bit not mounted correctly.

4. Machine is incorrectly mounted or sits

unevenly on floor.

5. Motor fan is rubbing on fan cover.

6. Centrifugal switch is at fault.

7. Motor bearings at fault.

1. Tighten.

2. Inspect/replace stripped or damaged bolts/nuts, and

re-tighten with thread-locking fluid.

3. Remove and re-install bit (

Page 21).

4. Tighten/replace fasteners; relocate/shim machine.

5. Replace dented fan cover; replace loose/damaged

fan.

6. Replace centrifugal switch.

7. Test by rotating chuck; rotational grinding/loose

shaft requires bearing replacement.

Machine slows or

stalls.

1. Workpiece material is not suitable for this

machine, or machine undersized for the

task.

2. Motor connection is wired incorrectly.

3. Workpiece crooked; hold-down clamp loose

or misadjusted.

4. Motor has overheated.

5. Centrifugal switch is at fault.

6. Motor is at fault.

1. Only drill wood products; make sure moisture

content is below 20% and use sharp bits/reduce

feed pressure.

2. Correct motor wiring connections (

Page 39).

3. Straighten or replace workpiece/adjust hold-down

clamp pressure (

Page 24).

4. Clean off motor, let cool, and reduce workload.

5. Adjust/replace centrifugal switch.

6. Test/repair/replace.

Содержание G0846

Страница 52: ......