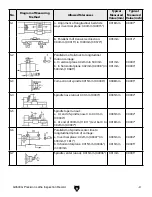

G0509G Precision Lathe Inspection Record

-2-

No.

Diagram of Measuring

Method

Allowed Tolerances

Typical

Measured

Value (mm)

Typical

Measured

Value (inch)

G1

a. Alignment of longitudinal bed slide

ways in vertical plane: 0.04mm (0.0015")

0.018mm

0.0007"

b. Parallelism of transverse direction:

0.04mm (0.0015") in 1000mm (39.370")

0.03mm

0.0012"

G2

Parallelism of tailstock to longitudinal

motion carriage:

a. In vertical plane 0.02mm in 500 mm

b. In horizontal plane 0.02mm (0.0008") in

500mm (19.685")

0.01mm

0.01mm

0.0004"

0.0004"

G3

Cam action of spindle 0.015mm (0.0006")

0.008mm

0.0003"

G4

Spindle nose runout 0.01mm (.0004")

0.005mm

0.0002"

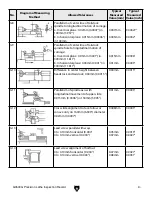

G5

Spindle taper runout:

a. At end of spindle nose 0 to 0.01mm

(0.0004")

b. At end of 300mm (11.811") test bar 0 to

0.02mm (0.0007")

0.005mm

0.018mm

0.0002"

0.0007"

G6

Parallelism of spindle center line to

longitudinal motion of carriage:

a. In vertical plane: 0.02mm (0.0007") in

300mm (11.811")

b. In horizontal plane: 0.015mm (0.0006")

in 300mm

0.005mm

0.013mm

0.0002"

0.0005"

G7

Spindle center runout: 0.015mm (0.0006") 0.01mm

0.0003"