Greenlee / A Textron Company

9

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

EK425 Battery-powered Crimping Tool

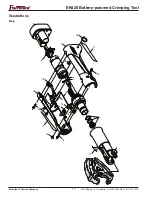

Maintenance

Each Operating Day

Before use:

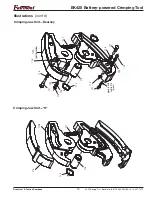

1. Inspect dies for wear or damage such as cracks,

gouges, or chips.

2. Inspect the tool for damage or leaks. If damage is

detected, return the tool to an authorized Fairmont

service center for inspection.

Skin injection hazard:

Do not use hands to check for oil

leaks. High pressure oil easily punc-

tures skin causing serious injury,

gangrene, or death. If injured, seek

medical help immediately to remove

oil.

After use:

1. Wipe all tool surfaces clean with a damp cloth and

mild detergent.

Troubleshooting

Before You Begin

1. Make sure that the battery is charged. Recheck the

battery after several minutes to make sure the bat-

tery is holding its charge.

Tool is inoperative.

Dirt, contaminants, etc., in ram area

Clean tool.

of tool.

Crimping tool battery contacts

Reform contacts.

damaged.

Tool components worn or damaged.

Return tool to an authorized

Fairmont service center.

Dies stop during operation.

Oil level is low.

Return tool to an authorized

Fairmont service center.

Air in hydraulic system.

Pull trigger and hold retract button

simultaneously. Hold for approximately

10 seconds.

Tool loses oil.

Damaged internal seal.

Return tool to an authorized

Fairmont service center.

2. Use a

nonflammable

contact cleaner or pencil

eraser to clean the electrical contacts on the battery

and crimping tool.

3. Reinstall the battery and check the tool again.

Problem

Probable Cause

Probable Remedy

2. Fully retract the ram. Place the tool in the carrying

case. Store in a cool, dry place.

3. Charge the battery.

Monthly

1. Thoroughly clean all surfaces.

2. Oil the pin joints.

Annually or After 10,000 Crimps

Return the tool to an authorized Fairmont service center

for inspection.

Do not use solvents or flammable

liquids to clean the crimping tool.

Solvents or flammable liquids could

ignite and cause serious injury or

property damage.