Greenlee Textron / Subsidiary of Textron Inc.

12

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

HG3505A / 42303 Portable Power Unit

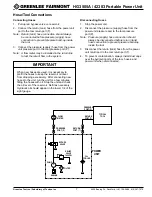

Hydraulic System - Oil and Filter

Maintenance (cont’d)

Perform this procedure in a clean environment.

Cleanliness is vital to maintain the service life of the

unit. Refer to Exploded View, HG3505A Power Unit.

1.

Engine must be shut off, and red bypass valve on

reservoir pulled up. Disconnect hoses and tool from

the unit.

2.

Place a pan under pipe plug (41) to catch oil as it

drains. The capacity of the hydraulic reservoir is 0.9

gallons (3.4 liters). Remove pipe plug, and allow the

system to drain.

Note: The hydraulic filter should be cleaned when

the system is drained. In order to clean the filter,

the reservoir must be removed. Cleanliness is

especially important when this procedure is

done.

3.

Remove cap nuts (40) and washers (39). Pull

reservoir (38) off of unit. Spacers (37) may fall free.

4.

Clean out any dirt which has accumulated in the

bottom of the reservoir.

5.

Remove filter (20), screwing it out of pump inlet

port. Inspect O-ring (21) for signs of cracks, wear

or damage. Clean filter with solvent, and dry with

compressed air. If filter is damaged, replace it.

6.

Reinstall filter. Check O-ring (34) for cracks, wear,

or damage. Install spacers (37) and reservoir,

secure with cap nuts (40) and washers (39).

Replace pipe plug (41).

7.

Remove breather/filler plug (22), clean filter in

breather/filler plug with solvent, and dry with com-

pressed air. Fill reservoir with new, clean oil. See

Specifications. Do not use oil which was drained

from reservoir or recycled oil. Replace breather/filler

plug.

Note: New hoses must be prefilled with hydraulic oil.

See Hose/Tool Connections.

Do not disconnect tool, hoses, or fittings while

the power unit is running or if the hydraulic fluid

is hot. Exposure to hot hydraulic fluid can cause

serious burns.