INSTRUCTION MANUAL

43180

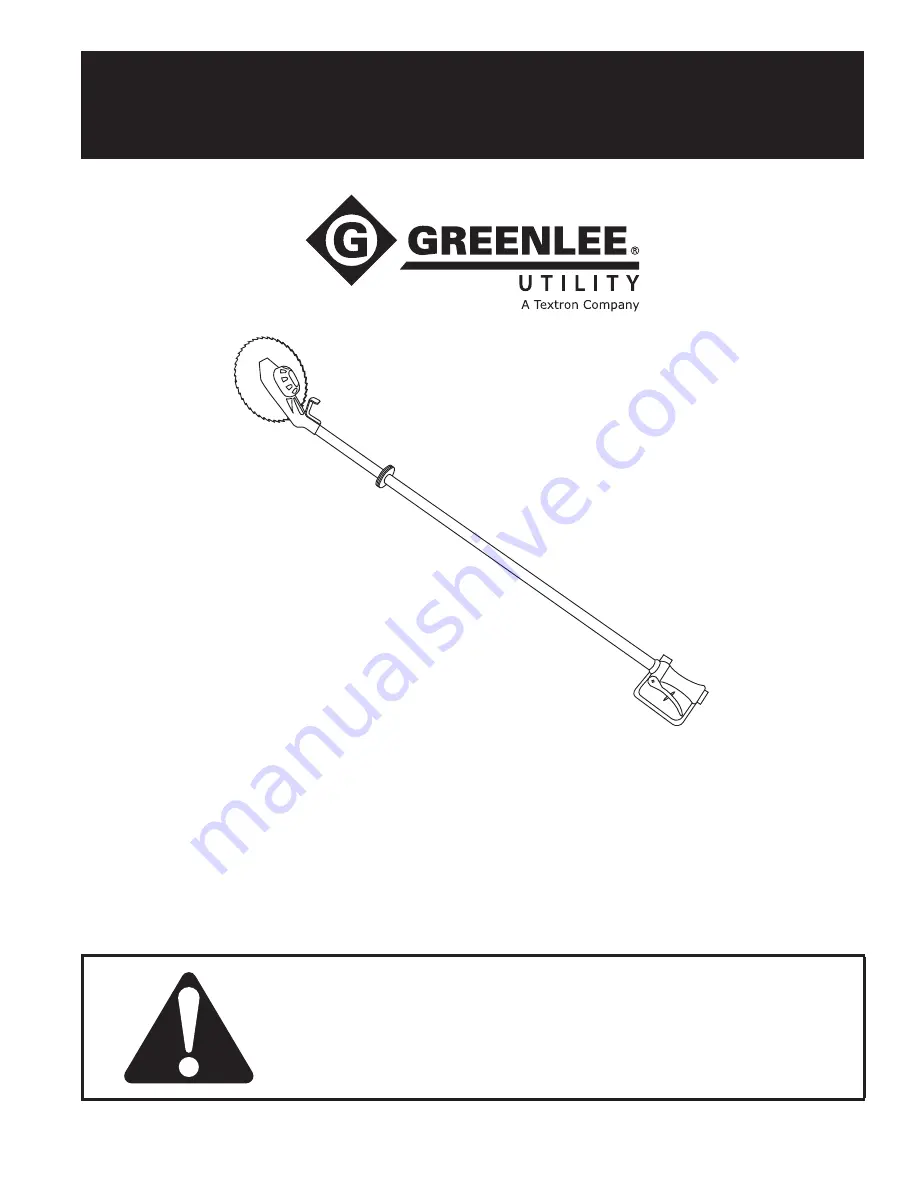

Overhead Circular Saw

99913097 REV 11

© 2010 Greenlee Textron Inc.

10/10

Read

and

understand

all of the instructions and

safety information in this manual before operating

or servicing this tool.

Register this product at www.greenlee.com