'BDUPSZTVQQMJFE

UIFSNBMCMBOLFU

BSPVOETMFFWF

$PNCJOBUJPO'JSF

4NPLF%BNQFS

'JSF

SBUFE

CBSSJFS

c

.BY

3FHJTUFS

JODMVEFT

HSJMMFBOE

0#%

4MFFWF-FOHUI

9

"

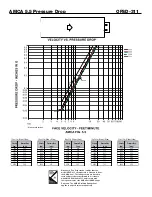

Actuator Space envelopes

The drawing below and corresponding table show the minimum dimensions

required for internal actuator mounting on OFSD-311s. The standard mounting

locations provide enough space for the mounting of actuators and controls plus

allowing space for a grille and duct connection (see Sleeve Length below).

Wall Opening Sizing

To accommodate for sleeve and thermal blanket thickness,

the wall opening must be oversized by 3⁄8 in. (9.5mm) as

shown. For example, if the nominal damper size required

is 18 in. x 14 in. (457mm x 356mm), the wall opening size

needs to be 18 3⁄8 in. x 14 3

⁄8 in. (467mm x 365mm). The

damper itself is undersized 1⁄4 in. (6mm) on each dimension

for an actual damper size of 17 3⁄4 in. x 13 3⁄4 in. (451mm x

349mm). This is also the inside dimensions of the sleeve (for

grille considerations).

Actuator Space

Honeywell

envelopes

ML-4XXX series MS-4120 series

MS4XXX series

‘X’ Dimension

5.88 in.(149mm)

5.88 in. (149mm)

Minimum Width

12 in. (305mm) 12 in. (305mm)

Minimum Height

12 in. (305mm) 12 in. (305mm)

AppLiCAtiOn DAtA

OFSD-311

Sleeve information

‘Sleeve Length’

=

Depth of Grille

(or Register)

+

X

(Actuator: see table above)

+

5 in. [127mm]

(Damper Width)

+

1.25 in. [31.8mm]

(for duct connection)

(round up to nearest length: 14 in., 16 in., 18 in.,

or 20 in. [356, 406, 457, 508mm])

‘Sleeve Gauge’

= 16 Ga. or 20 Ga. (1.5mm or 1mm)

Nominal Damper

Width +

3

8

in.

Nominal

Damper

3

/

8

in.

Wall

Fire Smoke Damper

With Sleeve And

Thermal Blanket

/

Combination Fire Smoke Dampers meeting the following specifica-

tions shall be furnished and installed where shown on plans and/or

as described in schedules. Dampers shall meet the requirements of

NFPA 80, 90A, 92A, 92B, 101 & 105 and further shall be tested, rated

and labeled in accordance with the latest edition of UL Standards 555

and 555S. Dampers shall have a UL555 fire rating of 1½ hours and be

of low leakage design qualified to UL 555S Leakage Class I.

Each damper shall be UL qualified for mounting out of the plane of

the wall to allow ‘through the grille’ access to actuator and controls.

Each damper /actuator combination shall have a UL555S elevated

temperature rating of 250° F (121ºC) minimum and shall be opera-

tional and dynamic rated to operate at maximum design air flow at its

installed location. Each damper shall be supplied with an appropriate

actuator installed by the damper manufacturer at the time of damper

fabrication. Damper actuator shall be (specifier select one of the fol-

lowing) electric type for 120 (24 or 230) volt operation. Each damper

shall be UL555S rated for leakage and airflow in either direction

through the damper.

Damper blades shall be of the double skin airfoil type and shall

have an equivalent thickness of 14 ga. (2mm) Damper frame shall

be galvanized steel formed into a structural hat channel shape with

reinforced corners. Bearings shall be sintered bronze sleeve type

rotating in extruded holes in the damper frame. Blade edge seals

shall be silicone rubber designed to inflate and provide a tighter seal

against leakage as pressure on either side of the damper increases.

Jamb seals shall be stainless steel compression type. Blades shall be

completely symmetrical relative to their axle pivot point, presenting

identical resistance to airflow in either direction or pressure on either

side of the damper.

Each damper shall be supplied with a factory mounted sleeve; sleeve

shall be wrapped with UL approved thermal barrier material. Each

damper shall be supplied with a 165°F (74ºC) RRL.

The basis of design is Greenheck Model OFSD-311.

Specifications

Copyright ©2006 Greenheck Fan Corporation

OFSD-311 Rev 3 June 2006