50 in.

32 in. (813mm)

50 in.

32 in. (813mm) 64 in. (1626mm)

50 in.

96 in. (2435mm)

50 in.

100 in.

(1270mm)

(1270mm)

32 in. (813mm)

(2540mm)

(1270mm)

32 in. (813mm)

128 in. (2540mm)

(1270mm)

Smoke Dampers meeting the following specifications shall be

furnished and installed where shown on plans and/or as described

in schedules. Dampers shall meet the requirements of NFPA 92A,

92B, 101 & 105 and further shall be tested, rated and labeled in

accordance with the latest edition of UL Standards 555S. Dampers

shall have a low leakage design qualified to UL555S Leakage Class II.

Each damper /actuator combination shall have a UL555S elevated

temperature rating of 250°F (121°C) minimum and shall be

operational at maximum design air flow at its installed location. Each

damper shall be supplied with an appropriate actuator installed by

the damper manufacturer at the time of damper fabrication. Damper

actuator shall be (specifier select one of the following) electric

type for 120 (24 or 230) Volt operation or pneumatic type for 25 psi

minimum (30 psi maximum) operation.

Damper blades shall be 16 ga. (1.5mm) galvanized steel 3V type with

three longitudinal grooves for reinforcement. Damper frame shall

be galvanized steel formed into a structural hat channel shape with

reinforced corners. Bearings shall be sintered bronze sleeve type

rotating in extruded holes in the damper frame. Blade edge seals

shall be silicone rubber designed to inflate and provide a tighter seal

against leakage as pressure on either side of the damper increases.

Jamb seals shall be stainless steel compression type. Blades shall be

completely symmetrical relative to their axle pivot point, presenting

identical resistance to airflow in either direction or pressure on either

side of the damper.

The Damper Manufacturer's submittal data shall certify all air

performance pressure drop data is licensed in accordance with the

AMCA Certified Ratings Program for Test Figures 5.2, 5.3, and 5.5.

Damper air performance data shall be developed in accordance with

the latest edition of AMCA Standard 500-D. Dampers shall be labeled

with the AMCA Air Performance Seal.

Damper must be rated for mounting vertically (with blades running

horizontal) or horizontally and be UL 555S rated for leakage and

airflow in either direction through the damper.

The basis of design is Greenheck Model SMD-202.

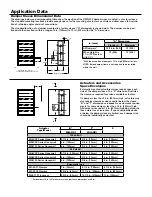

Damper Sizing Information

Dampers larger than maximum single section size are supplied as a factory assembly of two or more sections of equal size.

The following figures show maximum damper section size and assembly configurations for multi-section dampers.

Specifications

Transitioned Damper

Dimensions

When a fire/smoke damper is being used in conjunction with round or oval ductwork, the

SMD-202 can be supplied in a factory sleeve with round or oval transitions on both ends

of the sleeve. Dampers should be ordered to the duct dimensions. Drawings below show

overall damper size.

*

These dimensions are furnished approximately

1

/

4

in. (6mm) undersize, except round and oval dimensions which are approximately

1

/

8

in. (3mm) undersize.

Ts = (2)(Sleeve Thickness)

D* + 2 in. (51mm) +T s

D*

TYPE R

16 in. (406mm)

Min.

2

1

/

8

in.

D* + 2 in. (51mm)+T s

TYPE O

W

*

H*

W*

+ 2 in. (51mm)+T s

H* + 2 in. (51mm)+T s

W*

H*

TYPE C

H* + 2 in. (51mm)+T s

(54mm)

16 in. (406mm)

Min.

2

1

/

8

in.

(54mm)

16 in. (406mm)

Min.

W* + 2 in. (51mm)+T s

(54mm)

2

1

/

8

in.

Single Section

Double Section

Copyright ©2006 Greenheck Fan Corporation

SMD-202 Rev 4 June 2006