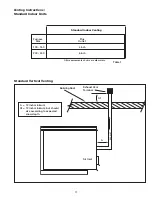

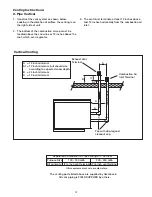

From

Gas

Gas Cock

1/8 in. Plugged

6 in. Trap

Ground Joint Union

To Controls

23

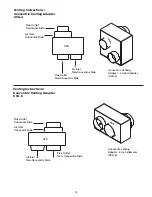

1. Single furnaces (furnace input 100 to 400 MBH)

have a single

3

⁄

4

inch connection. Double furnaces

(furnace input 500 to 800 MBH) have two

3

⁄

4

inch

connections, and triple furnaces (furnace input

1050 to 1200 MBH have three

3

⁄

4

inch connections.

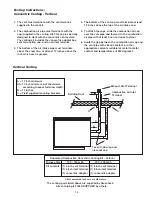

2. When connecting the gas supply, the length of the

run must be considered in determining the pipe

size to avoid excessive pressure drop. Refer to a

Gas Engineer’s Handbook for gas pipe capacities.

3. A drip leg should be installed in the pipe run to the

unit.

4. Install an easily accessible ground joint union and

a manual shut off valve (these are required by

some local codes) for emergency shut off and

easy servicing of the controls.

5. A

1

⁄

8

inch NPT plugged tap shall be installed

immediately ahead of the gas supply connection

to the furnace.

6. After gas piping is completed, carefully check all

piping connections for gas leaks. Use soap

solution or equivalent for testing. DO NOT use a

flame or other source of ignition to check for gas

leaks.

7. When leak testing pressures above 14 in. wc (

1

⁄

2

psi), close the field installed shutoff valve,

disconnect the furnace and its gas train from the

gas supply line, and plug the supply line before

testing.

8. When leak testing at pressures equal to or less

than 14 in. wc (

1

⁄

2

psi) close the field-installed

shutoff valve to isolate the unit from the gas

supply line before testing.

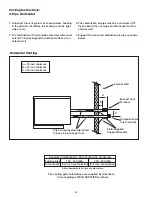

Recommended Piping to Controls

Gas Supply Pressure Requirements

Natural: 6 to 14 in. wc

LP: 11 to 14 in. wc

Start-Up Instructions:

Furnace - Gas Connection

Manual Shut

Off Valve

Содержание IGX

Страница 38: ...38 Documentation Date Problem Resolution...