309067

7

Intermediate Problem Solving

TYPE OF

PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK, refer to this column

Drain valve

leaks

1. Drain valve for correct torque and/or worn parts. Check for

debris trapped on seat.

1. Tighten to 185 in-lb (21 N

m). Clean

valve and replace with new gasket (55)

and sealant 110–110. See page 18.

No output:

motor runs

and pump

strokes

1. Paint supply.

1. Refill and reprime pump.

2. For clogged intake strainer.

2. Remove and clean, then reinstall.

3. For loose suction tube or fittings.

3. Tighten; use thread sealant on

npt threads of adapter fitting (43).

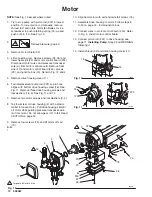

4. To see if intake valve ball and piston ball are seating

properly. See page 11.

4. Remove intake valve and clean. Check

ball and seat for nicks; replace as need-

ed. See page 11. Strain paint before us-

ing to remove particles that could clog

pump.

5. For leaking around throat packing nut which may indicate

worn or damaged packings. See page 11.

5. Replace packings. See page 11. Also

check piston valve seat for hardened

paint or nicks and replace if necessary.

Tighten packing nut.

6. Release gun trigger. Observe resting position of pump rod

(222).

6. If pump consistently comes to rest

with rod (222) fully extended, piston

packings and/or piston valve may be

worn. Service pump. See page 11.

No output:

motor runs but

pump does not

stroke

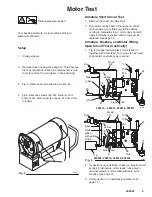

1. Displacement pump connecting rod pin (14).

See Fig. 9, page 11.

1. Replace pin if missing. Be sure retainer

spring (15) is fully in groove all around

connecting rod.

2. Connecting rod assembly (12) for damage. See page 15.

2. Replace connecting rod assembly. See

page 15.

3. Be sure crank in drive housing rotates; plug in sprayer and

turn on briefly to check. Turn off and unplug sprayer.

See page 15.

3. Check drive housing assembly for dam-

age and replace if necessary. See

page 15.

Spray pattern

variations

1. Spray tip worn beyond sprayer pressure capability.

1. Replace spray tip.

NOTE:

Smaller size tip provides

longer life.

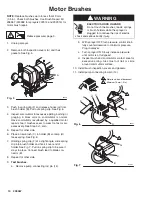

2. Motor control board (22a) by performing motor control

board diagnostics on page 13. If diagnostics indicate, sub-

stitute with a good board.

CAUTION:

Do not perform this check until motor armature

is determined to be good. A bad motor armature can burn

out a good board.

2. Replace board. See page 13.