11

308854

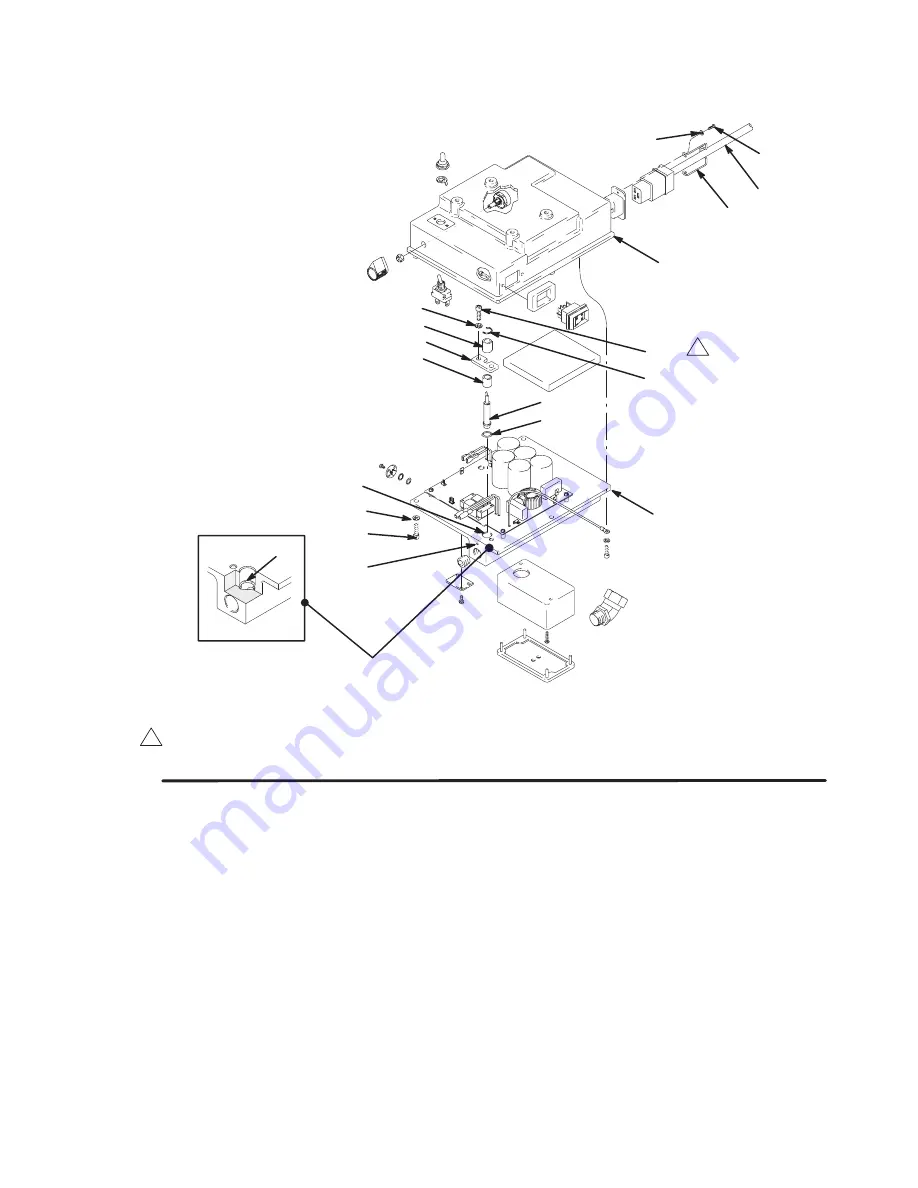

Pressure Control Repair

8185A

Fig 8

214

202

213

201

90 REF

230

89 REF

229

214

216

217

213

215

218

219

220

1

Torque to 150 in–lb (17 N.m)

C

A

B

1

2.

Carefully slide new o–ring (220) down bore (A) of

motor control (201) into o–ring groove (B). Make

sure o–ring is in groove around its entire circumfer-

ence.

NOTE:

P

T

FE

o–ring (220) is stiffer than a rubber

o–ring and may be difficult to place in groove.

3.

Carefully slide new transducer and plastic

spacer (217) down bore. Loosely attach

bracket (218), screws (213), and washers (214).

4.

Seat transducer into o–ring by drawing down

screws and washers until bracket is flush with

motor control surface.

5.

Carefully remove transducer and verify that o–ring

is seated correctly and not pushed out of groove. If

not seated correctly use new o–ring and repeat

steps 2 through 5.

6.

When o–ring is correctly installed, reinstall trans-

ducer and tighten screws to 150 in-lb (17 N

m).

Install spacer (216) and C-clip (215). Connect

electrical lead and assemble sprayer.

7.

Perform Flush and Prime procedures in STARTUP

of Operation Manual 308855 with compatible fluid.

8.

Inspect weep hole (C) for any leakage.

9.

If any leakage is present, replace o–ring repeating

steps 1 through 9.