307962 11

Air Motor Service

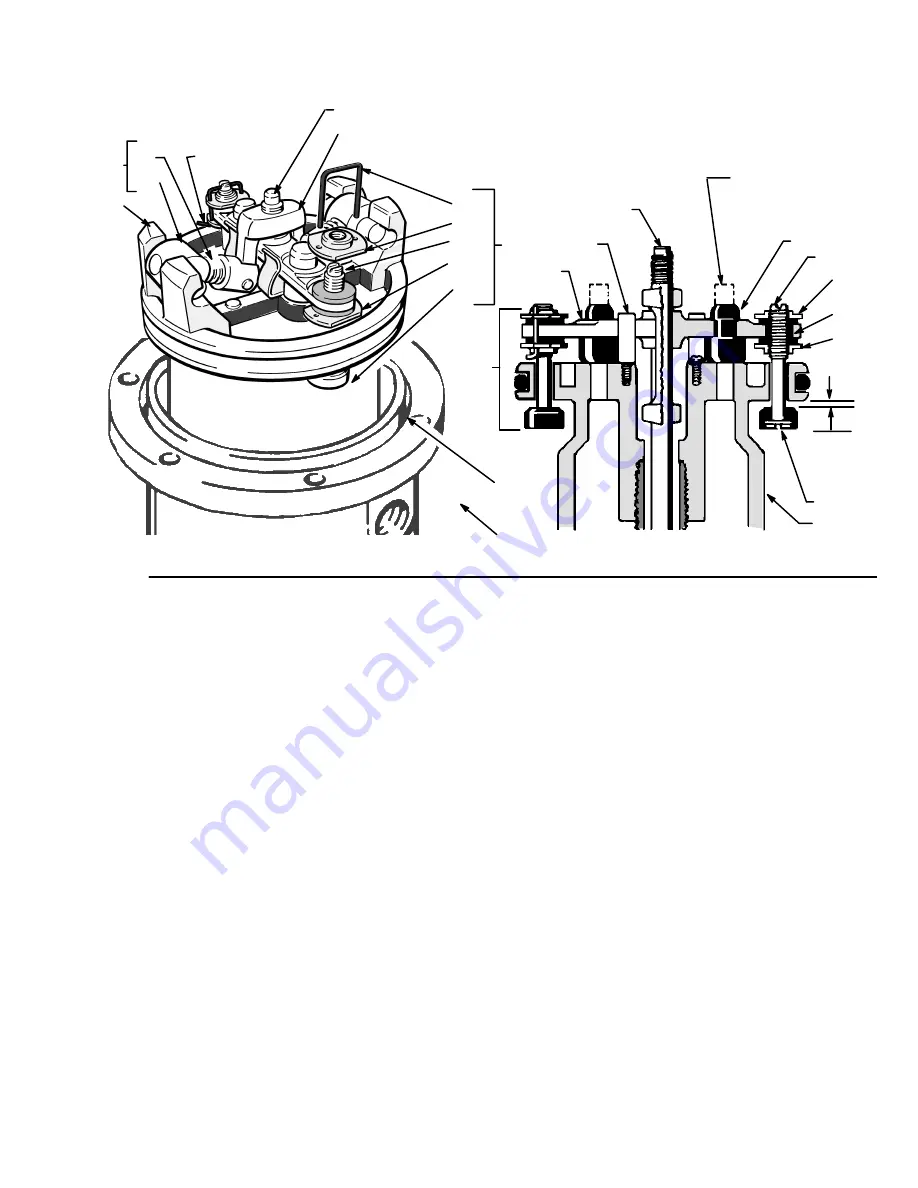

Fig 4

101

107

D

118

B

114A

113

116c

102

110

109

C

116a

120

113

114A

111

114B

112

116

CUT OFF TOPS OF

POPPETS AS

INDICATED BY

DOTTED LINES

101

119

0.145”

(3.68 mm)

CUTAWAY VIEW

114B

C

PUSH TOGGLES (B) IN

AND THEN UP

112

TURN WIRES UP

NOTE:

Refer to Fig. 4 for Steps 5 to 21.

5.

Use a screwdriver to push down on the yoke (107)

and snap the toggle assemblies (B) down.

6.

Remove the lockwires (118) and upper adjusting

nuts (114A) from the air transfer valves (C).

7.

Screw the stems (113) out of the grommets (111) and

lower adjusting nuts (114B).

8.

Remove the poppets (112) and inspect them for

cracks.

9.

Grip the rocker (109) with pliers, compress the spring

(110), swing the toggle assembly (B) up and away

from the piston lugs (D). Remove the parts.

10. Inspect the actuator (119) to be sure it is supported

by the spring clips (116a), but slides into them easily.

11. Remove the yoke (107), actuator (119) and the trip

rod (101).

12. Remove the poppets (120): stretch them out and cut

them with a sharp knife.

13. Pull the piston (116) out of the base (102). Remove

the o–ring (124) in the base casting.

14. Clean all parts thoroughly and inspect for wear or

damage. Inspect the polished surfaces of the piston,

piston rod and cylinder walls for scratches or wear.

Replace parts as necessary. Lubricate all parts with

a light waterproof grease.

15. Install the o-ring (124) in the groove inside the base

(102). Install the o-ring (123) around the rim of the

base. Install the o-ring (121) around the piston

(116c). Slide the piston rod down into the base (102).

16. Pull the poppets (120) into the actuator (119) and clip

off the top part of the poppets as shown with dotted

lines. See the

Cutaway View

.

17. Install the poppets (112) on the stems (113). Reas-

semble the stems (113), grommets (111), adjusting

nuts (114A,114B). Install the wires (118). Turn the

ends of the wires up to hold them in place.

18. Install the trip rod (101), actuator (119), yoke (107)

and the toggle assemblies (B) on the piston (116).

19. Adjust the stems (113) so there is a 0.145 in. (3.68

mm) clearance between the poppets (112) and the

piston (116) when the toggle assemblies are in the

down position. See the

Cutaway View

. Special

gauge, Part No. 171818, is available.

20. Snap the toggle assemblies (B) to the up position.

Reinstall the cylinder (115) and hold the trip rod (101)

in place with tool 207579. Apply a medium strength

thread locking compound to the threads of the trip

rod (101). Torque cap nut (131) to the trip rod (101).

21. Reassemble the air motor to the displacement pump.

Before mounting the pump, connect an air hose to

the air motor and run the pump to be sure it operates

smoothly.