Operation

310692D

13

Operation

Pressure Relief Procedure

1.

Turn off air and fluid supply.

2.

Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun to relieve pressure.

Applying the Fluid

When using the HVLP spray gun, instead of a conven-

tional airspray gun, you may need to use a slightly

slower hand movement and make fewer passes with the

gun to coat a part. This is due to the reduced spray

velocity produced by lower HVLP air pressures, along

with a larger fluid particle size because there is less air

to blow off solvents than what is produced by conven-

tional airspray. Take care to avoid runs or sags as you

spray.

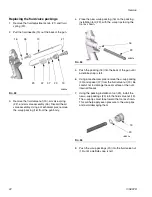

1.

To achieve the best results when applying fluid:

•

Keep the gun perpendicular and 6 to 8 inches

(150 to 200 mm) from the object being sprayed.

•

Use smooth, parallel strokes across the surface

to be sprayed with 50% overlap.

WARNING

Follow

Pressure Relief Procedure,

page

13 when

you stop spraying and before cleaning, checking, ser-

vicing, or transporting equipment. Read warnings,

page 3.

F

IG

. 11

ti4836a

F

IG

. 12

Incorrect

Correct

ti4843a

ti4842a

Содержание Delta Spray XT

Страница 25: ...Service 310692D 25 ...