Mounting and Setup

English, Revision 03, Date: 07.02.2012

15

3

Mounting and Setup

3.1

Testing a Transponder

It is possible to test the transponders with a reading antenna and a connected PC

(q. v. section 4.2 on page 20).

3.2

Mounting Transponder

Range and Positioning accuracy will be influenced by

-

Metal parts lying on the ground (sheet metals)

-

Reinforcement laid close to the transponder

-

Induction loops, e.g. formed by structural steel

NOTE!

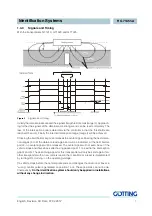

Individual metal rods have only little influence and may hurt the

metalfree area partially (see figure Figure 5 on page 16).

There is no influence on the positioning accuracy caused by

-

Environmental influences as snow, ice and water

-

Contaminations as oil, tar etc.

Basically the following Mounting Instructions for Transponder

G 71325 have to be observed

-

Keep a minimum distance of

500 mm

between the transponders.

-

Keep a minimum distance to the metal parts (see figure Figure 5 on page 16). The

interference on positioning accuracy and range depends on the size and the

range of the metal parts.

-

The minimum distance between conductors with a diameter smaller than 6 mm

has to be 2 mm.

Which end of the transponder is turned upwards is insignificant for the range or the

function.

3.2.1

Mounting in very solid Ground (e. g. concrete)

-

No additional protective casing necessary.

-

Vertical alignment required (otherwise a position error will be generated).

-

Transponder should be sealed (e.g. with a two component epoxy resin).

-

To protect the transponder use either a covering cap or apply an epoxy resin layer

(thickness approximately 1 cm). The drill hole should be wide enough so that the

cover cannot put pressure on the transponder.