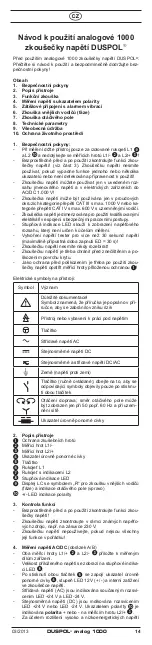

03/2013

DUSPOL

®

analog 1000

6

parts to be tested.

- The level of voltage applied is indicated by means of the

LED step indicator

8

.

- Actuate both push-buttons

5

to connect the plunger coil

level indicator

4

, the 12 V LED step (+/ -) and an internal

load in the voltage tester.

- Alternating voltages (AC) are indicated by the +24 V LED

and the -24 V LED lighting up simultaneously.

- Direct voltages (DC) are indicated by the +24 V LED or the

-24 V LED lighting up. The polarity indication

J

shows the

polarity

(+ or -) applied to the probe tip L2/+

3

.

- To differentiate between low-energy and high-energy volt-

ages (e.g. capacitively induced interference voltages), an

internal load in the voltage tester can be connected by ac-

tuating both push-buttons (see section 5).

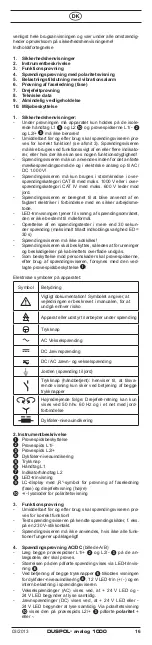

5. Load connection with vibration alert

(figure A/B

)

Both handles L1

6

and L2

7

are equipped with push-buttons

5

. Actuate both push-buttons to switch to a lower internal re-

sistance. Here, voltage is applied to a vibration motor (motor

with unbalanced mass). From approx. 200 V on, this motor is

set in rotary motion. With the voltage increasing, the motor’s

speed and vibration increases as well. The duration of the test

with a lower internal resistance (load test) depends on the level

of voltage to be measured. In order to avoid an inadmissible

warming of the device, it is provided with a thermal protection

(controlled reduction). With this controlled reduction, the speed

of the vibration motor is reduced and the internal resistance

increases.

The load connection (with both push-buttons being actuated)

can be used ...

- to suppress reactive voltages (inductive and capacitive

voltages),

- to charge capacitors,

- to trip 10/30 mA FI safety switches. The tripping of the FI

safety switch is done by testing the external conductor

(phase) to PE (earth). (figure D)

6. External conductor test (phase)

(figure C)

- Fully grasp the handles L1

6

and L2

7

, in order to en-

sure a capacitive coupling to earth.

- Apply the probe tip L2/+

3

to the system part to be tested.

During the single-pole external conductor test (phase),

make absolutely sure not to touch the probe tip L1/-

2

and that it remains contactless.

- If an “R” symbol is shown on the LC display

9

, the exter-

nal conductor (phase) of an AC voltage is applied to this

system part.

Note:

The single-pole external conductor test (phase) can be carried

out in an earthed mains from 230 V, 50/60 Hz (phase to earth)

on. Protective clothing and insulating conditions on site might

impair the function.

Attention!

The absence of voltage can only be determined by means of

a two-pole test.

7. Phase sequence test

(figure E/F)

- Fully grasp both handles L1

6

and L2

7

, in order to en-

sure a capacitive coupling to earth.

- Apply the probe tips L1/-

2

and L2/+

3

to two external con-

ductors (phases) of a three-phase mains and check whether

the external conductor voltage of e.g. 400 V is applied.

- A clockwise phase sequence (phase L1 before phase L2)

is given, if an “R” symbol is shown on the LC display

9

.

Nothing is shown on the LC display, if no clockwise phase

sequence has been detected.

- The phase sequence test always requires a countercheck!

If the LC display shows the clockwise phase sequence by

means of the “R” symbol, the LC display must show noth-

ing during the countercheck with the probe tips L1/-

2

and L2/+

3

being inverted.

If the LC display shows the “R” symbol in both cases, the

earthing is too weak.

Note:

The phase sequence test can be carried out in an earthed

three-phase mains from 230 V, 50 / 60 Hz (phase to phase)

on. Protective clothing and insulating conditions on site might

impair the function.

8. Technical data

- regulation: DIN EN 61243-3: 2011, IEC 61243-3: 2009

- nominal voltage range: 12 V to 1,000 V AC/DC

- nominal frequency range f: 0 to 60 Hz

- max. indication error: U

n

±15%, ELV U

n

+0% -15%

- internal resistance of measuring circuit: 180 kΩ,

- current consumption of measuring circuit: I

s

< 6,0 mA

(1,000 V)

- current consumption of load circuit: I

s

< 550 mA (1,000 V)

- polarity indication: + 24 V LED, - 24 V LED, + 12 V LED, -

12 V LED (with push-buttons being actuated)

- external conductor (phase) test and phase sequence test:

≥ U

n

230 V, 50/ 60 Hz

- vibration motor, start: ≥ U

n

200 V

- overvoltage category: CAT IV 600 V,

CAT III 1,000 V

- protection category: IP 65 (DIN VDE 0470-1 IEC/ EN

60529)

6 - first index: protection against access to dangerous

parts and protection against solid impurities, dustproof

5 - second index: protected against water jets. The device

can also be used in the rain.

- max. allowable Duty cycle: 30 s (max. 30 seconds), 600 s off

- weight: approx. 250g

- length of connecting cable: approx. 1,000 mm

- operating temperature and storage temperature range:

- 20 °C to + 45 °C (climatic category N)

- relative air humidity: 20 % to 96 % (climatic category N)

- times of controlled reduction (thermal protection):