VGH SERIES

OM-06114

OPERATION

PAGE C - 5

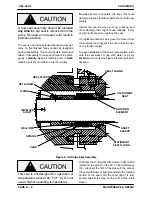

uid from an external source. When handling clean

liquids, flushing liquid is taken from the pump dis

charge and supplied through the seal flush line

supplied with the pump.

When handling abrasive or tacky liquids, it may be

necessary to supply fresh lubricating liquid from an

external source. Be sure the liquid supplied to the

seal is compatible with the liquid being pumped,

and that its flow is controlled to prevent dilution.

Consult the factory if flushing is required.

Bearings

The bearing housing

was

not

lubricated when

shipped from the factory

. See

INSTALLATION

,

Section B, and lubricate the bearing housing as in

dicated. Check the constant level oiler regularly

and keep it full of oil. When lubrication is required,

flip the transparent constant level oiler cup open

and fill it with SAE No. 30 non‐detergent

oil.

Under normal conditions, drain the bearing hous

ing once each year and refill with clean oil. Change

the oil more frequently if the pump is operated con

tinuously or installed in an environment with rapid

temperature change.

Monitor the condition of the bearing lubri

cant regularly for evidence of rust or mois

ture condensation. This is especially im

portant in areas where variable hot and

cold temperatures are common.

For cold weather operation, consult the factory or a

lubricant supplier for the recommended grade of

oil.

Power Source

Consult the literature supplied with the power

source, or contact your local power source repre

sentative.